Used Butt Reducer for sale (2,599)

Krotoszyn

Krotoszyn Buttermilk pasteurization line

Alfa Laval, Tetra PakC8-K8M, CP19555, HP-5032/170

Germany

Germany Reduction sleeves

WNTfuer Direktklemmung

Denkendorf

Denkendorf Button head

RenishawPH10M

+44 20 806 810 84

Denkendorf

Denkendorf Button head

RenishawMIH

Denkendorf

Denkendorf RST button

Zeiss

Discover more used machines

Denkendorf

Denkendorf Button

RenishawTP2 TP6 TP20

Tönisvorst

Tönisvorst External quick button

KroeplinOD60100BJ AF01E032

Tönisvorst

Tönisvorst Digital interior button

IntertronicEID 1010

Tönisvorst

Tönisvorst Three D buttons

GarantTyp 359520

Tönisvorst

Tönisvorst Reduction sleeves

verschiedene GroessenMK

Czech Republic

Czech Republic Reduction device

Tvářecí strojBEA 2

Zielona Góra

Zielona Góra Butterfly table for prefabrication

BOOSTONER03H2R/900

Zielona Góra

Zielona Góra BOOSTON - Butterfly table from stock 12m

BOOSTONER-03HR/1200

Berlin

Berlin Butter Texturiser

EGLI AGEBR 1500 D

Alkmaar

Alkmaar Reduction oven

Bader & Scheffer GmbH

Suffolk

Suffolk Flaker for frozen blocks - meat, fruit, butter etc.

Magurit314

Geiselwind

Geiselwind Primary reduction gearing transmission for creel drive

LinckVG

Würzburg

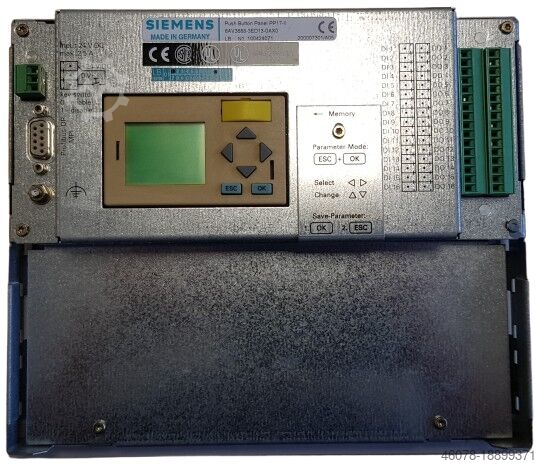

Würzburg Siemens Push Button Panel PP17-II

Siemens6AV3688-3ED13-0AX0

Ireland

Ireland Butternut Squash Peeler

Jay CraftNNN

Derby

Derby New Butter Extruder and Shaping Machines By Dairy Machinery UK

Dairy Machinery UKDMUK EXSH1

Liverpool

Liverpool Timber Frame Butterfly Station

H&M

Mallabia

Mallabia Lever push button

ALFAMATICTROMBOLINE MOP B-15

Mõisaküla

Mõisaküla Complete sawmill (stationary)

Söderhamn ErikssonCustomill

Åsby

Åsby Logintake with debarker

Marijampolė

Marijampolė Industrial robot

OSCCobra

Used Butt Reducer (2,599)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84