Used Extracted Wall for sale (10,494)

Cochem

Cochem Extraction / chip extractor

EmmegiMG4-VP

Wiefelstede

Wiefelstede MIG/MAG hose package with welding fume extraction

unbekannt4,3 m wassergekühlt

Wiefelstede

Wiefelstede Dust extraction fan 0.75 kW

Coral S+SGRINDEX

+44 20 806 810 84

Wiefelstede

Wiefelstede Filter system extraction system

KrämerGFR 64/1.75-70

Rödermark

Rödermark Sandblasting system with extraction

MHGSMG 45 k-P

Discover more used machines

Janville

Janville Wall-mounted stirrer

--

Janville

Janville Single wall tank

GEA-

Janville

Janville Wall mounted mixer

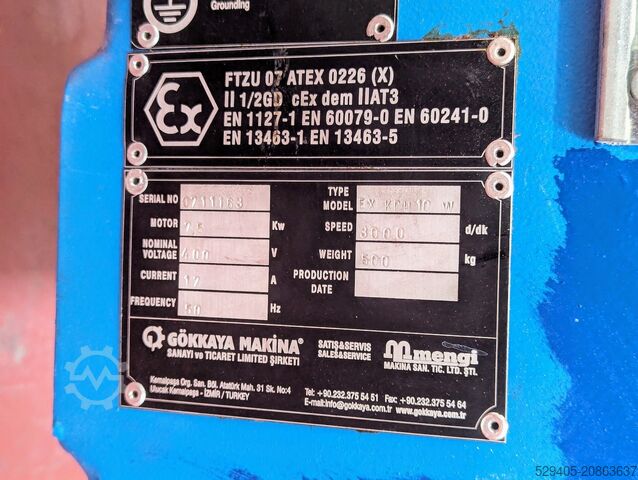

Gökkaya MachineryAKO®WALL EX KDH 10W

Janville

Janville Dissolver with wall support

--

Janville

Janville Stirrer on wall support

--

Netherlands

Netherlands Used Stacking box steel fixed construction stacking box with four closed walls, L: 800, W:

Kruizinga102866S-GB

Netherlands

Netherlands Used Stacking box steel fixed construction with four closed walls, L: 975, W: 610, H: 510

Kruizinga98-7343GB

Netherlands

Netherlands Used Euronorm stacking bins walls + floor perforated, L: 600, W: 400, H: 190 (mm). 28ltr,

Kruizinga98-7329GB-PAL

Netherlands

Netherlands Used Euronorm stacking bins all walls closed + open handles, L: 600, W: 400, H: 270 (mm).

Kruizinga98-6827GB-PAL

Netherlands

Netherlands Used Euronorm stacking bins all walls closed + open handles, L: 600, W: 400, H: 120 (mm).

Kruizinga98-7274GB-PAL

Netherlands

Netherlands Used Euronorm stacking bins all walls closed, L: 600, W: 400, H: 145 (mm). 24ltr, L: 600,

Kruizinga98-6771GB-PAL

Netherlands

Netherlands Used Stacking box steel fixed construction with four closed walls, L: 960, W: 580, H: 510

Kruizinga98-6989GB

Netherlands

Netherlands Used Stacking box steel fixed construction with four closed walls, L: 1215, W: 810, H: 415

Kruizinga98-6921GB

Netherlands

Netherlands Used Euronorm stacking bins KLT all walls closed, L: 590, W: 395, H: 145 (mm). 21ltr, L:

Kruizinga98-5376GB-PAL

Netherlands

Netherlands Used Euronorm stacking bins walls + floor perforated, L: 600, W: 400, H: 320 (mm). 62ltr,

Kruizinga98-606GB-PAL

Netherlands

Netherlands Used Stacking box steel fixed construction stacking box all walls closed, L: 1050, W: 850,

Kruizinga98-0251GB

Netherlands

Netherlands Used AGF boxes walls + floor perforated, L: 500, W: 300, H: 260 (mm). 29ltr, L: 500, W:

Kruizinga99-5469GB-PAL

Tatabánya

Tatabánya Extraction,Oil mist,Smoke separator

LOSMA ASPIROFILTERAS 7

Bitburg

Bitburg Clean air extraction system frequency converters

AL-KO350 + P FU

Bitburg

Bitburg Clean air extraction system

AL-KOPower Unit 300 P

Used Extracted Wall (10,494)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84