Used Halls for sale (401)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Clickout

Auction ended

Mannheim

Mannheim

6,896 km

Vertical panel saw

TK UNIVERSVP 950M

Condition: used, Year of construction: 1992, functionality: fully functional, 1 unit Panel Saw TK UNIVER SVP 950M

Operating hours: 1054h, as per pictures and inspection, self-dismantling

Color: green

Nkodpfsx Szycsx Adwst

Year of manufacture: 1992

Dimensions (L/W/H): 600x250x80 cm

Condition: used

Payment method: advance bank transfer

Storage location: joinery/workshop hall 1

Shipping: Collection only – no shipping available for this item!

Listing

Löwenberger Land

Löwenberger Land

6,581 km

Heating & blower

Herz / Lauber

Call

Condition: like new (used), Year of construction: 2022, functionality: fully functional, We are selling a converted overseas shipping container equipped with a Herz Firematic 130 boiler system. The heating unit has a capacity of 130 kW and is connected to a Lauber heat exchanger. Additional doors have been installed in the heating container to facilitate maintenance and inspection, ensuring easy access to the system. The boiler is fired with wood pellets, and the integrated pellet bunker holds approximately 1.5 tons. Both the heating container and the Lauber unit must be dismantled prior to transport, but thanks to the container design, they can be easily loaded for relocation. The interior of the heating container is lined and treated with a special coating to prevent condensation drip formation inside. The Lauber unit installed is a Lauber Energy Utilization Center type L-ENZ 80+ (5.50 kW fan). Both machines are in nearly new condition with only minimal operational use. The total operating hours are currently 3,577, which equates to approximately 149 days of operation. Both units were manufactured at the end of 2022 and have been in use since around May 2023.

What is this system suited for? It can be used for heating halls, buildings, construction sites, etc., as well as for drying bulk or natural materials such as wood, wood chips, horse manure, or any free-flowing bulk goods.

Please note: The drying boxes shown in some of the photos were part of our operational setup but are not included in this offer. For further details on dimensions, weight, and loading, please refer to the attached technical drawings.

Nkjdoybbphspfx Adwet

Listing

Siedlce

Siedlce

5,967 km

Pallet Scale

CORMAKW3T

Call

Condition: new, Year of construction: 2025, 3000 kg Platform Scale – A Professional Warehouse Scale for Large and Heavy Loads

The 3000 kg platform scale is a robust and precise device designed for use in demanding warehouse, production, and logistics environments. With a large steel platform measuring 120 x 120 cm and a load capacity of up to 3 tons, it allows for weighing both standard pallets and large industrial components, containers, or heavy machine parts. It’s an indispensable tool for daily operations, enabling fast, accurate, and repeatable weight measurements of various types of cargo.

Durable Construction and Reliability for Everyday Use

The platform is made from high-quality steel, ensuring long-lasting durability and resistance to heavy use. Its anti-slip, ribbed surface enhances safety—keeping loads stable even under maximum weight. The low profile design (10 cm height) allows for easy loading using a pallet jack or forklift, while adjustable feet ensure perfect leveling on any surface. This makes the scale suitable for modern warehouses with flat floors as well as production halls where minor floor unevenness may occur.

Technical Specifications:

Nkedjxay Hbspfx Adwst

Platform dimensions: 120 x 120 cm

Structure height: 10 cm (adjustable by approx. 4–5 cm)

Maximum load capacity: 3000 kg (3 tons)

Readability/accuracy: 0.5 kg (500 g)

Sturdy steel platform with anti-slip surface

Precision and Ease of Use

The platform scale is equipped with high-precision load cells that ensure reliable readings, even under full load. With a readability of 0.5 kg, the scale is suitable not only for heavy-duty weighing but also for quality control processes where precise weight measurements are crucial. The electronic display with an intuitive control panel allows for quick result reading, significantly improving operator efficiency and reducing the risk of errors.

Applications in Logistics and Industry:

This 3000 kg warehouse scale has a wide range of applications across multiple sectors. It’s ideal for:

Incoming and outgoing shipment checks

Weighing pallets before transport

Inventory management in warehouses

Quality control and production monitoring

Handling in distribution centers and wholesale facilities

This device enhances work efficiency, saves time, and ensures accurate weight measurements essential in logistics, trade, and heavy industry.

Why Choose the 3000 kg Platform Scale?

By investing in a professional electronic scale for pallets and loads, you’re getting equipment that will serve you reliably for years. Its durable steel construction, high load capacity, and precise load sensors make it suitable for even the most demanding working conditions. Thanks to the universal platform dimensions and stable design, the scale is practical, easy to operate, and simple to maintain.

NOTE: Pallet not included in the set.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Siedlce

Siedlce

5,967 km

Mast pallet truck

CORMAKWRHS 1610

Call

Condition: new, Year of construction: 2025, If you run a warehouse or need to move heavy items, a mast pallet jack may be the perfect tool for you. A mast trolley is a type of lift truck that will allow you to lift and move pallets in a warehouse. Our offer includes trolleys that can lift loads up to 3,500 mm.

Introduction to mast hand pallet trucks

Mast hand trucks used mainly for warehouse work and production halls for loading and unloading goods. Thanks to its basic features such as versatility, solid construction and lifting height, it has many applications and offers many benefits for operators.

What is a mast pallet truck?

A mast pallet truck is a type of lift truck that is equipped with a mast with high lifting capacity. The mast is usually made of a solid material, such as steel, and can lift a load to a certain height. Thanks to this, the mast pallet truck allows you to move heavy goods to different levels in the warehouse.

Application of mast lift trucks

These are reliable transport devices that are widely used in various industries. They are essential in warehouses, where they enable easy operation of pallet racks and loading and unloading pallets from trucks. In addition, they are also popular in production halls, where they enable the transfer of materials to various workstations.

This universal model of pallet truck is an ideal solution to increase efficiency in warehouses, production halls and other places where it is necessary to move heavy pallets. Thanks to its advanced functions, the WRHS 1610 pallet truck with a capacity of 1,000 kg and a lifting capacity of 1,600 mm is an irreplaceable tool in the field of logistics and warehousing. They are perfect for unloading and loading cars.

Technical parameters

Nodsricgaspfx Adwjkt

Load capacity 1000 kg

Lifting height 1600 mm

Fork dimensions (LxW) 1150 x 145 mm

External fork width 550 mm

Width between forks 230 mm

Height with lowered forks 1970 mm

Height with raised forks 1970 mm

Minimum fork height 90 mm

Total length 1630 mm

Total width 740 mm

Turning radius 1400 mm

Swivel wheels 180 x 50 mm

Fork rollers 74 x 70 mm

Weight 181 kg

Listing

Siedlce

Siedlce

5,967 km

Mast pallet truck

CORMAKWRHS 1013

Call

Condition: new, Year of construction: 2025, Characteristics of the WRHS1013 trolley:

The WRHS 1013 mast pallet truck is a solid device designed to effectively move and lift pallets and heavy loads in various workplaces. This particular model boasts a lifting capacity of an impressive 1,000kg, meaning it can handle pallets with large volumes of goods, increasing its versatility and suitability across a range of industries.

The most important feature of the trolley is its ability to lift loads to a height of 1,300 mm. This means it can handle pallets of different heights and allows you to place them on racks, shelves or anywhere else you need to store goods. Thanks to this function, the WRHS 1013 trolley helps optimize storage space.

In addition, the WRHS 1013 pallet truck is equipped with a durable mast that ensures stability and safety when lifting and lowering loads. It also has an ergonomic handle that makes it easier for the operator to operate the truck, which translates into work efficiency and reduces the risk of injuries.

This model of pallet truck is an excellent tool to increase efficiency in warehouses, production halls and other places where it is necessary to move heavy pallets. Thanks to its advanced functions, the WRHS 1013 pallet truck with a load capacity of 1,000 kg and a lifting capacity of 1,300 mm is an irreplaceable tool in the field of logistics and warehousing.

Technical data

Load capacity 1000 kg

Lifting height 1300 mm

Fork dimensions 1150 - 145 mm

External fork width 550 mm

Width between forks 230 mm

Height with lowered forks 1670 mm

Height with raised forks 1670 mm

Minimum fork height 90 mm

Total length 1600 mm

Total width 750 mm

Turning radius 1200 mm

Swivel wheels 150 x 50 mm

Fork rollers 80 x 60 mm

Nkodpfx Aericbcedwet

Weight 179 kg

Listing

Siedlce

Siedlce

5,967 km

Mast pallet truck

CORMAKWRHS 1020

Call

Condition: new, Year of construction: 2025, Characteristics of the WRHS1020 trolley:

The WRHS1020 mast trolley is a device designed for lifting and moving pallets. It has a load capacity of up to 1,000 kg and the ability to lift objects to a height of up to 2,000 mm. This is an excellent solution for loading and unloading pallets from delivery vehicles, but is also useful in warehouses, production halls and construction sites.

Nksdpforicc Eox Adwet

It is characterized by stability and safety when moving loads. It can be controlled using the handle. The forks have rounded ends, which makes it easier to slide them under the pallets. The handle is covered with a layer of rubber, which improves work comfort and reduces the risk of injuries.

Lifting the load can be done using a hand lever or, in the case of light items, using a foot control, which guarantees ease and precision in operation. The WRHS1020 mast trolley is also equipped with a specialized hydraulic pump that allows the forks to be lowered smoothly, allowing for precise and safe placing of loads.

Its durable construction ensures long service life, and the foot brake increases safety by preventing the stroller from accidentally moving. Polyurethane wheels enable smooth driving on various types of surfaces, which increases the convenience of operation. Thanks to them, you can use the stroller even on difficult terrain.

It is worth adding that the stroller has an overload valve, which additionally protects against overload when transporting heavy loads. Not only is it a solid and durable device, but spare parts and service are also easily available. We offer service and spare parts immediately available, with the possibility of delivery throughout the country.

Technical data

Load capacity 1000 kg

Lifting height 2000 mm

Fork dimensions (LxW) 1150 x 145 mm

External fork width 550 mm

Width between forks 230 mm

Height with lowered forks 1565 mm

Height with forks raised 2545 mm

Minimum fork height 90 mm

Total length 1600 mm

Total width 750 mm

Turning radius 1400 mm

Swivel wheels 180 x 50 mm

Fork rollers 80 x 60 mm

Weight 259 kg

Listing

Siedlce

Siedlce

5,967 km

Electric scissor pallet truck

CORMAKHT15E

Call

Condition: new, Year of construction: 2025, Electric Scissor Pallet Truck HT15E

The HT15E electric scissor pallet truck is a multifunctional warehouse device designed for convenient and safe pallet handling. It combines the features of a classic electric pallet truck and a lift table, allowing not only transport but also lifting loads up to 800 mm. It performs perfectly in packing areas, sorting facilities, assembly halls, and production lines.

With a load capacity of 1500 kg, the HT15E model easily handles most standard pallets. Its robust scissor construction ensures stability and safety of lifted goods, while the electric motor provides smooth, fast, and effortless lifting. The operator doesn’t need to use physical force – simply press a button and the truck does all the work.

Powered by a high-performance battery, the truck enables long, uninterrupted operation. Charging is easy with a standard mains charger. This ensures that the HT15E is always ready for use, regardless of workload intensity.

The truck is equipped with an ergonomic control tiller, a precise hydraulic system, and high-durability wheels that ensure smooth movement even on uneven surfaces. Its compact design allows easy maneuvering in narrow aisles, while the lifting function helps maintain proper working posture – significantly improving operator comfort and safety.

The HT15E is the perfect choice for companies that value efficiency, ergonomics, and reliability. It performs excellently both in small warehouses and large logistics centers where precision and work speed are key.

Key Advantages:

Load capacity: 1500 kg – stable operation even with heavy loads

Nksdpfoxurpdex Adwet

Lifting height: 800 mm – ideal for order picking and packing

Electric lifting system – quick and effortless lifting

Reinforced steel construction – resistant to wear and overload

High-performance battery – long operating time on a single charge

Quiet operation and easy control – comfort in everyday use

Technical Specifications:

Parameter Value

Load capacity 1500 kg

Fork height 85–800 mm

Fork length 1170 mm

Fork width 160 mm

Fork spread (outside) 540 mm

Fixed wheel ⌀ 75×50 mm (2 pcs)

Steering wheel ⌀ 180×50 mm (2 pcs)

Battery 12 V / 50 Ah

Weight 115 kg

Listing

Siedlce

Siedlce

5,967 km

Lifting bar manual lift transport lever

CORMAKWJ03 (3000kg)

Call

Condition: new, Year of construction: 2025, Our lever up to 3000 kg is an irreplaceable tool in every warehouse, workshop or production hall, where solidity and reliability are important. The lever is made of the highest quality steel, which guarantees its durability and resistance to mechanical damage. The solid frame ensures stability when lifting, minimizing the risk of accidents and damage to the items being moved. The lifting height of the bar is 90 mm.

The transport lever with a capacity of 3,000 kg is the ideal solution for carrying a variety of loads in various work environments. It is perfect for both small workshops and large warehouses or production plants. Maximum load capacity of 3000 kg, durable steel construction, transport wheels for easy movement, ergonomic and comfortable handle and versatile use make our lever an irreplaceable tool for lifting and moving heavy loads. If you are looking for a reliable tool for lifting and moving heavy loads, our transport lever with a capacity of 3,000 kg will meet your expectations. Choose a proven solution that will increase the efficiency of your work and ensure safe use.

Please contact us and purchase our transport lever. We guarantee the highest quality and satisfaction with the use of our product.

Product characteristics:

Nkedpfx Aevxq Nhjdwjt

Total length: 1400 mm

Pipe diameter: 38x3 mm

Nose plate thickness: 11 mm, tapers at the end

Nose plate width: 65 mm

Load capacity: 3000 kg

Total weight: approximately 8 kg.

Manufacturer: Cormak

Listing

Siedlce

Siedlce

5,967 km

Gantry crane

CORMAKPK2

Call

Condition: new, functionality: fully functional, Year of construction: 2025, Product characteristics:

The Cormak 2-ton gantry crane is a specialized industrial machine designed for moving heavy loads in industrial halls. It consists of many elements, including a supporting frame, a trolley and other components that enable easy, safe and precise movement of loads horizontally and lifting and lowering them using hooks. The model is distinguished primarily by its durability and stable construction, thanks to which it can be used in difficult industrial conditions. This crane is also resistant to torsion, which is ensured by additional reinforcements used in the structure.

One of the most important features of the crane are four return rollers that ensure easy movement of heavy loads. These rollers are extremely durable and abrasion-resistant, which guarantees their long service life. Another important element are the built-in parking brakes, which ensure safe stopping of the crane in any place.

Height adjustment on the device is easy and safe when the lever is not loaded and with the help of two screws securing each bracket. The crane's structure is durable and stable, and its ease of use makes it an ideal solution for companies that need an efficient and reliable machine for moving heavy loads. Moreover, the multitude of retrofitting options allows it to meet even more applications and tasks in various industrial sectors.

Thanks to its efficiency and precision, the overhead crane is a versatile work tool that can be additionally equipped with rope or chain winches. After using a block, an overhead crane with a winch or chain allows for even more precise and effective movement of heavy loads. As a result, it is used in many industrial sectors, such as construction, metallurgy and the chemical industry. Using a gantry crane, you can carry out warehouse, assembly, loading and unloading works, as well as repairs. All these activities are performed with high precision and safety, which in turn translates into higher quality of work.

Technical parameters:

Load capacity: 2000 kg

Nkodpfx Asridh Nsdwet

Double T-carrier: 100 x 180 mm

Height: 2400 mm – 3600 mm

Width: 2360 mm

Weight: 168 kg

Overhead crane without a winch visible in the photos

Listing

Siedlce

Siedlce

5,967 km

ZZ1500x3000 Plasma Cutter

CORMAKZZ-1530

Call

Condition: new, Year of construction: 2025, Product characteristics

The plasma burner or oxygen-gas CNC1 burner is a mobile device designed for cutting shapes out of a metal sheet. The machine does not require anchoring, thus reducing the assembly time considerably. Additionally, it enables for placing the machine in any location within the hall without any new expenses. The machine is equipped with an excellent quality wheel system that together with the low weight portal makes the plotter one of the fastest machines available on the market.

The machine can be used for manual and automatic cutting. It is equipped with a digital controller that enables cutting out complicated shapes. The machine proves itself very well in the shipbuilding, machine-building and power industry. CNC1 has been equipped with a precise system of X/Y axes guides. The burner is controlled by Sino-USA electronic production system that is characterized by a high precision and elimination of the errors occurring during operation. The machine is very easy to configure. A manual configuration is possible for simple shapes and automatic configuration is possible for more complicated figures. The cutting pattern and the burner motion are shown on a display.

An original FastCAM software is attached to the machine for easy configuration. The software is in English which makes the work easier.

FastCAM is a technological CAD/CAM program, which is intended for designing and defining cutting paths of the elements cut out by CNC burning machines. The program shall be installed on an office PC or on a portable computer. After defining the way of cutting the operator receives a ready control code, which should be transferred to the control system of the machine. FastCAM program is a standard element of our machines.

BASIC INFORMATION

User-friendly interface – easy operation, even for people without prior experience of working with such programs as FastCAM

Import of drawings in the *.txt format from any programs similar to e.g. AutoCAD, SolidWorks etc.

MAKRO – a library containing standard shapes enables creating figures without the necessity of drawing them in CAD system. The program provides 2D figures

NESTING – an optimal usage of sheet metal thanks to the automatic arrangement of elements on a sheet

DEMO – shows a working path without having to turn on the plasma source or oxygen

VOLTAGE HEIGHT CONTROLLER

The machine is equipped with THC (a voltage control of the plasma burner blowtorch height). A precise control (+/- 0.1 mm) of the plasma blowtorch distance from a sheet metal during cutting. Higher accuracy and absence of defects which capacitive sensors and roller disks have. The parameters of the controller are collected automatically from the Automatic Cutting Parameters Selection table.

Technical data

Power supply

230 V

LCD

7" color

Code format

G-Code

Working dimensions

1500×3000 mm

Cutting speed

Njdpfsvxhwvjx Adwskt

50–3000 mm/min

Illustrations are preview only, the device is sold without the table.

Manufacturer: Cormak

Listing

Siedlce

Siedlce

5,967 km

Mast pallet truck

CORMAKP513A

Call

Condition: new, Year of construction: 2025, Mast Lift Truck P513A – Efficient and Reliable Pallet Stacker

Its robust construction made of high-quality steel ensures excellent stability and durability, making it a reliable device for intensive use. The truck is equipped with forks that allow precise lifting of loads, and the manual lifting mechanism provides full control over the process. This enables the operator to maneuver the truck accurately and effortlessly, even in narrow working spaces.

Thanks to its swivel wheels, the truck is easy to move across various surfaces, making it a highly versatile tool. It is an ideal solution for transporting and lifting loads in warehouses, distribution centers, production halls, and any place where precise and efficient goods handling is required.

Nedpfx Aow Rlffodwjkt

The CORMAK P513A manual mast truck is a dependable tool that offers comfortable operation by eliminating the need for manual lifting of heavy loads. It is an excellent choice for companies looking for a solid and efficient solution for material handling and transport.

Technical Specifications

Load capacity: 500 kg

Lifting height: 1300 mm

Fork dimensions (L × W): 800 × 130 mm

Fork outer width: 220–540 mm

Height with forks lowered: 1610 mm

Height with forks raised: 1610 mm

Minimum fork height: 85 mm

Overall length: 1380 mm

Overall width: 570 mm

Turning radius: 1100 mm

Steering wheels: 120 × 50 mm

Fork rollers: 70 × 30 mm

Weight: 168 kg

Listing

Siedlce

Siedlce

5,967 km

Gantry crane

CORMAKPK1

Call

Condition: used, functionality: fully functional, Year of construction: 2025, Characteristics of the gantry crane:

An overhead crane with a lifting capacity of up to 1 ton is a versatile device that can be used in various areas, such as unloading, loading, repairs, warehouse work, assembly and many others. It is an extremely useful tool in halls, workshops and warehouses where effective moving and lifting of heavy objects is needed.

The device has been specially designed to work on horizontal and flat floors, allowing easy movement along straight lines. Thanks to four return rollers, the crane ensures smooth movement around the working space, and parking brakes ensure safe stopping in appropriate places.

Adjusting the unloaded height of the crane is simple and safe thanks to a lever and two safety screws on each bracket. Additionally, the stability and durability of the crane are ensured by a solid structure and additional transverse struts that ensure torsion resistance.

An additional advantage of an overhead crane with a lifting capacity of up to 1 ton is the possibility of installing a trolley with a manual drive, which allows for even greater flexibility and freedom of movement on tracks or guides.

Advantages of the gantry crane:

Designed for loading and unloading, assembly, repair or storage work in workshops and halls on horizontal and smooth floors

Easy to move and install using four return rollers with parking brakes

Easy and safe height adjustment when unloaded via a lever and two securing screws per bracket

Stable and durable, torsion-resistant structure thanks to additional transverse struts

Possibility to install a trolley with a manual drive

Technical parameters of the crane:

Load capacity 1000 kg

Height 2500 mm – 3600 mm

Width 2300 mm

Double T carrier 76 x 140 mm

Total width (base) 2400 mm

Upper beam width 2550 mm

Nkjdpfsxzr Rzsx Adwst

Total height 2520 mm / 3720 mm

Working width for winch 1750 mm

Support frame tensioners 4 pcs

Transverse reinforcements of the supporting beam 2 pcs

Weight 142 kg

The overhead crane can be retrofitted with rope or chain winches after using a block or trolley.

Overhead crane without a winch visible in the photos

ATTENTION!! The machine is a return, without packaging, without zip.

Listing

Siedlce

Siedlce

5,967 km

Platform scissor truck

CORMAKTA8015

Call

Condition: new, Year of construction: 2025, Basic advantages of the scissor platform trolley

The scissor platform trolley with a capacity of 800 kg and a lifting capacity of 1500 mm is a versatile and reliable device that is used in various industries and work environments. This robust scissor trolley has been designed to facilitate the movement of heavy loads and to enable lifting heights of 1,500 mm.

Thanks to its load capacity of 800 kg, the scissor platform trolley is able to handle a wide range of materials, such as boxes, pallets, machines, and other heavy objects. It has a durable structure that guarantees stability and safety during load manipulation.

Lifting loads with a scissor platform trolley

The lifting height of 1500 mm is a feature that allows access to hard-to-reach places. The ability to raise the platform to such a height allows work to be performed at different levels, which increases the efficiency and flexibility in the applications of this scissor lift truck.

Nksdpfjric Itjx Adwet

The scissor platform trolley is easy to operate and maneuver. It is equipped with ergonomic handles and intuitive controls that enable the operator to smoothly control the truck and precisely position the load. Additionally, it is equipped with brakes, which ensures safe stopping of the scissor trolley at the desired place.

Product for transporting electric batteries with a capacity of 800 kg

The scissor platform trolley is an excellent tool for efficiently transporting electric batteries and car batteries. Its solid construction and stability allow for the safe transportation of even heavy and delicate elements, such as heavy batteries. Thanks to the scissor lifting mechanism, the trolley allows easy loading and unloading of batteries, which is important both in the production process and in the area of warehouse logistics. The flexibility and precision of movement of the scissor platform trolley make it an irreplaceable tool in the industry dealing with the storage and movement of electrical components, contributing to increasing the efficiency and safety of processes related to the handling of electric batteries and car batteries.

Summary of the advantages of a scissor lift truck

This particular version of the scissor platform trolley is characterized not only by high load capacity and lifting capacity, but also by solid construction, durability and ease of operation. It is an irreplaceable tool for warehouses, production halls, logistics centers and other places where it is necessary to effectively move and lift heavy loads to heights. Attractive prices of platform trolleys and fast delivery of orders in our store will enable effective support for your business.

Technical parameters

MAXIMUM LOAD 800 kg

LIFTING HEIGHTS 480-1500 mm

PLATFORM DIMENSION 1220x610 mm

TOTAL DIMENSIONS 1520x700x1000

WHEEL DIAMETER 150 mm

WEIGHT 172 kg

Listing

Siedlce

Siedlce

5,967 km

Electric mast truck

CORMAKQ15E35

Call

Condition: new, Year of construction: 2025, A mast trolley with an electric drive, a load capacity of 1,500 kg and a lifting height of 3,500 mm, is an ideal warehouse device for transporting heavy loads. Solid steel construction ensures stability when lifting. Polyurethane rollers facilitate movement on uneven surfaces. Thanks to this, the mast trolley allows you to quickly and safely move loads at various levels and in various conditions.

Introduction to electric mast pallet trucks

The CORMAK Q15E35 electric mast lift truck is a versatile and efficient solution for material handling and lifting to a height of 3.5 m. Thanks to its innovative design and advanced technology, this trolley is ideal for use in warehouses, production halls and distribution centers.

Key advantages of a pallet lift truck with a capacity of 1,500 kg

Nedpferh E D Ujx Adwekt

The technical specifications of this model include the ability to lift to an impressive height of 3,500 mm, which enables efficient manipulation of loads at various levels. The trolley's load capacity is 1,500 kg, which makes it an excellent tool for handling medium and heavier loads.

Machine features

A solid structure made of high-quality steel ensures greater stiffness and stability when lifting.

Thanks to the use of a special system, the handle of the pallet truck allows the steering to be transferred directly to the wheel.

Built-in rectifier.

Lifting the forks to the maximum height without load - only 25 seconds!

Maintenance-free motor with brushless technology.

Battery charge indicator on the control box.

Safety switch.

Built-in controller protects the battery against discharge or damage.

Sealed, maintenance-free AGM battery.

WE DO NOT REQUIRE inspections during the warranty period.

Technical parameters

MAX LIFTING HEIGHT

3500mm

CAPACITY

1500 kg

CENTER OF GRAVITY

600mm

FORK LENGTH

1150mm

OUTER FORK WIDTH

570mm

HEIGHT WITH FORKS LOWER

2330 mm

HEIGHT OF RAISED MAST

4000mm

HEIGHT OF LOWER FORKS

85mm

TOTAL WIDTH

810mm

TOTAL LENGTH

1745mm

CLEARANCE

30mm

TURNING RADIUS

1390mm

TRAVEL SPEED WITH / WITHOUT LOAD

3.5/4 km/h

LIFTING SPEED WITH/UNLOAD

140/200 mm/s

LOWERING SPEED WITH/UNLOAD

120/100 mm/s

HILL CLIMBING ABILITY WITH/UNLOAD

5/7%

WORK BRAKE TYPE

electromagnetic

DRIVE ENGINE POWER

0.75 kW

LIFTING ENGINE POWER

2 kW

BATTERY VOLTAGE/CAPACITY

12V 75 I 120 Ah

WHEEL MATERIAL

Polyurethane

LIBRA

586 kg

Listing

Siedlce

Siedlce

5,967 km

Platform scissor truck

CORMAKTA15B

Call

Condition: new, Year of construction: 2025, The scissor trolley with a capacity of 150 kg is a compact device ideal for working in tight spaces and ensuring stable load lifting. It has a wheel lock and a security system, which translates into safety while working. The trolley is used in many industries, including warehouses and production halls.

Machine description

The scissor platform trolley with a capacity of 150 kg is a unique tool that is perfect for various warehouse, production and logistics applications. Thanks to its solid construction and innovative technical solutions, this trolley is an invaluable partner in the area of lifting and moving heavy loads.

Its main characteristic feature is the scissor lifting mechanism, which enables smooth and precise lifting of loads weighing up to 150 kg to the appropriate height. This makes this stroller irreplaceable in situations where it is necessary to ergonomically raise and lower objects while ensuring the user's safety.

The scissor platform trolley has been designed with ease of use and maneuverability in mind. Equipped with solid wheels, it allows smooth movement even in difficult terrain conditions. Additionally, the compact design allows for efficient movement even in tight warehouse spaces.

The safety of use of the scissor platform trolley with a capacity of 150 kg is guaranteed by the use of high-quality materials and safeguards that prevent the load from falling accidentally. Intuitive control allows you to precisely adjust the lifting level, which in turn translates into precise operation and optimized use of the truck in various tasks.

In short, a scissor platform trolley with a capacity of 150 kg is a reliable tool that combines durability, functionality and safety, making working with heavy loads much more effective and comfortable.

Nkjdpfx Asv Aiinodwjt

Technical parameters

MAXIMUM CAPACITY 150 kg

LIFTING HEIGHTS 225-745mm

PLATFORM DIMENSION 740 x 450 x 35 mm

PLATFORM HANDLE HEIGHT 825mm

WEIGHT 42 kg

Standard equipment:

Reinforced polyurethane wheels

Ergonomic handle

Sealed hydraulic foot pump

Adjusting the descent speed of the platform

Lock on the road wheels

Manufacturer: Cormak

Listing

Germany

Germany

6,627 km

Filter Device

IFSIF-Vario M 1600

Call

Year of construction: 2015, condition: used, Technical details:

suction capacity: 1600 m³/h

filter: siehe Foto

weight of the machine approx.: 85 kg

connected load: 0,75 kW

dimensions L x W x H: ca. 1,0 x 0,6 x 0,7 m

Oil mist separator - Dry separator

Mechanical air filter for oil and emulsion mist

Application:

Extraction and filtering of oil and emulsion mist as well as smoke and aerosols

Space requirement:

kThe IF-Vario can be installed at the extraction point for ceiling extraction, as well as on the hall ceiling, on the walls with wall racks or on single-column bases in the hall for recirculating air operation.

Protection class IP 54

Nedswhu Thepfx Adwjkt

*

Listing

Bachhagel

Bachhagel

6,757 km

Oil mist extraction

IVATIVAT Air FTower 20.000M

Call

Condition: used, Year of construction: 2015, operating hours: 5,231 h, functionality: fully functional, machine/vehicle number: 2015019, type of input current: three-phase, overall weight: 1,590 kg, input voltage: 400 V, total width: 1,756 mm, total length: 2,066 mm, total height: 3,643 mm, power: 15 kW (20.39 HP), input frequency: 50 Hz, Equipment: oil mist separator, type plate available, Oil mist extraction from the workshop, plug & play filter tower for extraction during emissions of coolant lubricants in production halls.

Filter ventilation tower IVAT Air FTower 20,000M.

Ideal for aerosols, oil mist, emulsion mist and vapors.

Industrial hall filtration ventilation – suitable for various technical manufacturing processes in production facilities, primarily in metalworking.

In many cases, the extraction systems installed directly on machines for coolant recovery are either insufficiently efficient or not installed at all. Setup operations on machine tools, frequent opening of machine enclosures, or missing covers on machining heads can result in oil mist escaping from the machine area and reaching work zones, where employees are exposed to harmful mists and vapors.

Installing a ventilation tower significantly improves air quality at workstations and should be considered the ideal complement to industrial hall filtration ventilation – especially where complete separation of oil mist via coolant recovery systems is either not possible or difficult to implement.

Includes automatic room air and temperature monitoring.

An innovative PLC control system compares sensor data and detects any exceedance of thresholds at workstations or increased temperature directly at the hall ceiling, then fully automatically regulates temperature and air quality.

Filters are barely used, see images.

Nkedpfx Asxqf Hzjdwst

Price ex works, pick-up only.

Listing

Lublin

Lublin

5,918 km

Four-sided planer

REX HOMS 310-K

Call

Condition: excellent (used), Year of construction: 1980, functionality: fully functional, REX HOMS-310-K Four-sided Planer

Year of manufacture: 1980

Serial number: 18.568

Power: 91.69 kW

It has not been used since 2021.

Nkedpfx Adewfqh Ajwst

The machine was stored in a closed production hall for the entire period and is fully functional.

After purchasing the machine, the electrical cables were replaced with new ones.

We rate the technical condition as very good - visually there are visible traces of use, but technically everything works properly. The reason for the sale is the end of glued wood production.

Maximum working width: 305 mm

Minimum working width: 50 mm

Maximum workpiece height on 2 sides: 310 mm

Maximum workpiece height on 4 sides: 160 mm

Minimum workpiece height: 17 mm

driven upper and lower feed rollers

Listing

Wiefelstede

Wiefelstede

6,929 km

Floodlights

PhilipsMVF 616

Call

Condition: used, Area lighting, floodlight, workshop lamp, lamp, hall lamp, hall lighting, pendant lamp, industrial lamp

-Power: 150 watts

Nkjdpfxsd N Ddpj Adwet

-Number: 13x lights available

-Price: per piece

-Dimensions: 390/320/H310 mm

-Weight: 7.1 kg/piece

Listing

Wiefelstede

Wiefelstede

6,929 km

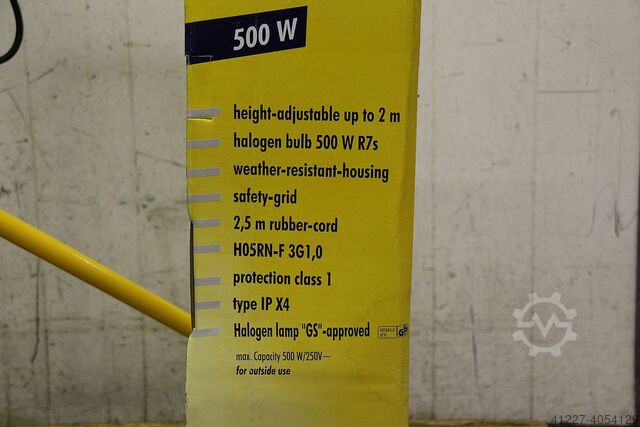

Halogen spotlights

Schwabe500 W

Call

Condition: used, Area lighting, floodlight, workshop lamp, lamp, hall lamp, hall lighting, pendant lamp, industrial lamp

-Power: 500 watts

-Number: 6x lights available

-Price: per piece

Nkedpfx Asd N Ddvodwjt

-Dimensions: 245/170/ H620 mm

-Weight: 4.8 kg/piece

Listing

Wiefelstede

Wiefelstede

6,930 km

Chain hoist with chassis 1250 kg

KonecranesXN16 2004 B2

Call

Year of construction: 2003, condition: used, Electric chain hoist, crane, hall crane, assembly crane, hand trolley, rolling trolley, crane trolley, trolley trolley, crane trolley, crane trolley, trolley

-Manufacturer: Konecranes, electric chain hoist with chassis

-Chain hoist: Type XN16 2004 B2 load capacity 1250 kg

-Main stroke: 4 m/min

-Fine stroke: 1 m/min

Njdpfx Aon Srvredwskt

-Chain length: 4.65 m

-Crane chassis: beam width max. 255 mm

-Dimensions: see photo technical. drawing

-Transport dimensions: 1200/800/H440 mm

-Weight: 173 kg

Trust Seal

Dealers certified through Machineseeker

Listing

Wiefelstede

Wiefelstede

6,930 km

Bearing cap

INA260x150x54

Call

Condition: good (used), bridge crane, hall crane, assembly crane, flange hub, bearing cover

-Bearing cover: Type 260x150x54

.: 1031 4155

-Number: 6x bearing caps available

-Price: per piece

Nsdpfev Il Iqox Adwokt

-Dimensions: Ø 260 x 55 mm

-Weight: 7.4 kg/piece

Listing

Wiefelstede

Wiefelstede

6,930 km

Bearing cover

unbekannt220x115x42

Call

Condition: good (used), Rope protection cage, for rope pulley, steel rope pulley, rope deflection pulley, crane rope, four-rope orange peel grapple, polyp grapple, mechanical orange peel grapple, shell grapple, ship unloading grapple, scrap grapple, garbage grapple, rope grapple, bridge crane, hall crane, assembly crane, flange hub, bearing cover

-Bearing cover: Type 220x115x42

-Bolt circle: Ø 180 x 13 mm

Nksdjv Imahopfx Adwot

-Number: 8x bearing caps available

-Price: per piece

-Dimensions: Ø 220 x 42 mm

-Weight: 5.7 kg/piece

Listing

Wiefelstede

Wiefelstede

6,930 km

Shaft coupling

SchanPBK Ø 200 mm

Call

Condition: good (used), Coupling, power coupling, gear coupling, transmission coupling, flange hub for crane undercarriage, running wheel, bridge crane, hall crane, assembly crane, flange hub, coupling star, claw coupling, shaft coupling

-Shaft coupling: Schan PBK Ø 200 mm

-Bolt circle: Ø 170 mm

-Dimensions: see photos

-Quantity: 1 piece available

-Dimensions: Ø 200 x 60 mm

Njdpfov Impcox Adwekt

-Weight: 4.0 kg

Listing

Wiefelstede

Wiefelstede

6,930 km

Crane beam 15t

Sietas8520/240/H620 mm

Call

Year of construction: 1979, condition: good (used), Adjustable traverse, crane traverse, hall crane, workstation crane, crane hook traverse, load traverse, balancing traverse

-Manufacturer: JJSietas, crane traverse balancing traverse, for the transport of various loads

-Load capacity: 15 t (6x 2.5t)

-Load hooks: 6 pieces with sheet metal claws clamping range 0 - 25 mm, see photos

Nksdpelbdl Eofx Adwst

-Dimensions: see photo sketch

-Dimensions: 8520/240/H620 mm

-Own weight: 1200 kg

We make it easier for you to find: "halls"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Halls (401)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month