Used Vertical Grinding for sale (10,948)

Wymysłów

Wymysłów Double grinding block

REMADS 12/ST

Hungary

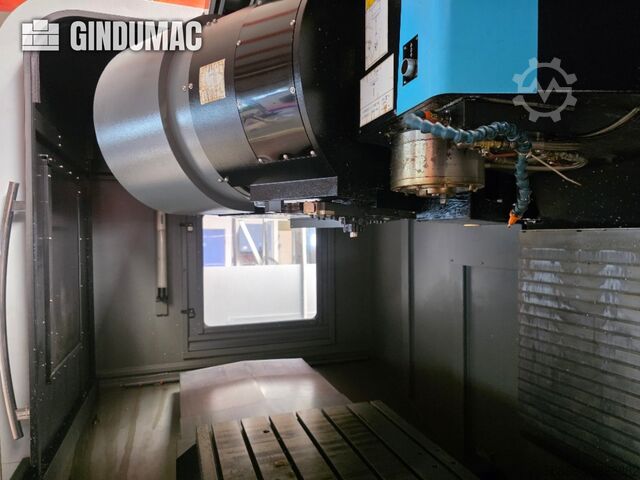

Hungary Vertical Machining Centre

HurcoVMX84i

Singapore

Singapore Vertical machining center

DMG MORIDMC 635V ecoline

+44 20 806 810 84

Matelica (MC)

Matelica (MC) Machining Centres - Vertical

STAMAMC 326.2 TWIN

YENİMAHALLE/ ANKARA /

YENİMAHALLE/ ANKARA / Crushing plant

PolygonmachVSI-700 vertical shaft impactor 132kw

Discover more used machines

Koprki

Koprki 2500 L Vertical Cosmetic Reactor/Process Vessel Ekato Model SRA 2500

EKATOSRA 2500

Konin

Konin Double grinding block

Geb.Bayer, Greif, Gisro

Hungary

Hungary Vertical Machining Centre

MazakVariaxis i-600

Sremska Mitrovica

Sremska Mitrovica Grinding machine for bandsaw welds

IdealSMH 060

Плевен

Плевен Internal grinding machine

WotanSN 205/13L-25

Emskirchen

Emskirchen Vertical Press Delivery

HeidelbergVSA-66/M.D

Asenovgrad

Asenovgrad CNC Vertical Lathe RASOMA DZS 250-2

RASOMADZS 250-2

Germany

Germany Surface grinding machine

OKAMOTOACC 450 AV

Poland

Poland Vertical Machining Centre

DMG DECKEL MAHODMC 64V linear

Nattheim

Nattheim Grinding table

HolzkraftHST 3000 Premium

Плевен

Плевен Vertical slotting machine

STANKO7D430

Fevziçakmak

Fevziçakmak VICTOR Vcenter-55 Vertical

VictorVcenter-55

Асеновград

Асеновград Vertical machining center

MazakMTV-655/60

Stroncone

Stroncone Glass grinding machine

NEPTUNROCK 11

Trittau

Trittau Milling machining centers - vertical

MATSUURAV.PLUS-800

Brno-město

Brno-město Vertical machining center

DMG MORIDMC 635 V Ecoline

Плевен

Плевен Thread grinding machine

STANKO5K822B

Heilbronn

Heilbronn Vertical Milling Center

BridgeportVMC 1000P

Асеновград

Асеновград Vertical machining center

DMG MORICMX 70 U

Плевен

Плевен Centerless grinding machine

Koenig & BauerMultimat 250-2

Used Vertical Grinding (10,948)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84