Used Dna Sequencer for sale (472)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Ahaus

Ahaus

7,000 km

Hydr. pressbrake

ALPMACB175-3100

Call

Condition: used, Year of construction: 2025, pressure 175 t

chamfer lenght 3100 mm

distance between columns 2600 mm

column arm 410 mm

ram stroke speed 160 mm/sec

work speed 10.0 mm/sec

return speed 120 mm/sec

work stroke 265 mm

dayligth 480 mm

table height 900 mm

table width 90.0 mm

oil volume 230 ltr.

voltage 400 Volt

total power requirement 18.5 kW

weight 10500 kg

range L-W-H 4100 x 2000 x 2820 mm

Demonstration/demo machine (!!)

from our exhibition (like NEW)

with very few operating hours

ALPMAC manufacturer video:

?v=_FxXyPAcxlE

?v=YfkX9RwWv_0

ALPMAC product video Model B:

?v=lmT1tfy43WE

-----

MODEL SERIES B175-3100 - CNC electro-hydraulic press brake with:

* increased installation height

* increased cylinder stroke

* increased projection

-----

! MANUFACTURED FROM CERTIFIED QUALITY STEEL (ST 37-42-52)

! HIGH PERFORMANCE HYDRAULIC COMPONENTS (HAWE GERMANY)

! SMOOTH RUNNING DUE TO LESS OPERATING PRESSURE (50-60 DB)

! INDUCTION HARDENED & CHROME-PLATED CYLINDER PISTONS FOR CONTINUOUS USE

! BACK STOP COMPONENTS MADE FROM CAST ALUMINUM

! BACK STOP WITH POWERFUL DRIVE MOTOR (1.0 KW)

! MACHINE TABLE MADE OF ROBUST & RESISTANT STEEL (C45)

Equipment:

- CNC electro-hydraulic press brake

- DELEM CNC control model "DA-58T" graphics/touchscreen

* 2D graphic programming

* 15" color TFT screen with high resolution

* Bending sequence calculation

* Product programming and display in real size

* USB interface

- CNC controlled axis: Y1 - Y2 - X - R - crowning

- CNC electro-motorized back stop (X axis)

* on ball screws

* Travel path .. max. 750 mm

* Travel speed X axis .. 350 mm/s

* with 2x manually adjustable stop fingers

- CNC electro-motorized height adjustment (R axis)

* Travel path .. max. 250 mm

- CNC electro-motorized Table crowning

- ROLLERI Rehfuß upper tool "PS 135.85-R08", system "A"

* including quick-change clamping

* including crowning device in the tool holder

- ROLLERI split universal die block "M 460 R"

Bljdpsxaa Eqsfx Afhjc

* including 1x die shoe "C 1050-R"

- Safety device at the rear: light barrier

- HAWE hydraulic components

- FIESSLER AKAS laser protection device in front of the machine (incl. FPSC)

- 2x front support arms with SLIDING system

* easy and keyless height adjustment

- FIESSLER freely movable double foot control

- CE mark / declaration of conformity

Listing

Fumane (Verona)

Fumane (Verona)

6,710 km

Syrup Room

ALFA LAVAL

Call

Condition: used, Used syrup room with pasteurizer Alfa Laval

This second hand Syrup Room is a complete processing section designed for the preparation of concentrated base syrups and finished syrups for beverage production. Engineered for integration upstream of a premix and an isobaric filler, it supports efficient industrial packaging workflows in a used bottling line. It is ideal for beverage production environments that require reliable sugar dissolving, thermal treatment, and hygienic storage prior to mixing, carbonation, and filling.

The system covers the full syrup preparation sequence: simple syrup creation from treated water and sugar, finished syrup blending with concentrates, acids, colors, and flavors, and hygienic storage in stainless steel tanks. A dedicated pasteurizer helps ensure product stability, while mixers and pumps support consistent, repeatable processing. This Syrup Room is well suited for soft drink formulations such as cola, tonic, and other flavored carbonated beverages, and it integrates seamlessly with premix units that add CO2 just before the filling machine. The plant layout and component selection make it a practical solution for upgrading or expanding a used bottling line in the beverage production sector.

Technical Specifications & Performance Data

Sugar dissolver: AICMA

Pasteurizer: Alfa Laval

Storage tanks (finished/simple syrup): 4 x 4,000 L Cavalzani

Storage tanks (finished/simple syrup): 3 x 2,000 L Bertuzzi

Mixers and pumps: Included for circulation, transfer, and blending

Process materials: Treated water, sugar/sweeteners, fruit concentrates, flavors, additives

Construction: Stainless steel AISI 304/316 process equipment

Cleaning: CIP-ready design for sanitary cleaning in place

Bjdpfx Afoxywg Sjholc

Advanced Automation & Control Systems

The Syrup Room features a centralized control panel with analog/digital selectors for process management, enabling operators to supervise dissolving, thermal treatment, storage, and transfer operations. Dosing can be achieved using precision pumping and flow control to maintain recipe accuracy. Hygienic design, sanitary valves, and instrument connections support repeatability and quality. The configuration is suitable for integration with plant-level automation and recipe control, with clear operator interfaces that simplify changeovers and routine adjustments while supporting safe and reliable operation.

Production Line Integration Capabilities

This processing plant is designed to feed finished syrup to a premix unit, where it is blended with treated water and CO2 immediately before the isobaric filler. It can be integrated inline with existing beverage production and industrial packaging equipment and is compatible with used bottling line layouts handling both PET and glass bottling downstream. Recipe-based operation supports multi-flavor portfolios, and transfer connections allow straightforward tie-in to upstream water treatment and downstream premix and filling systems.

Listing

Wald

Wald

6,842 km

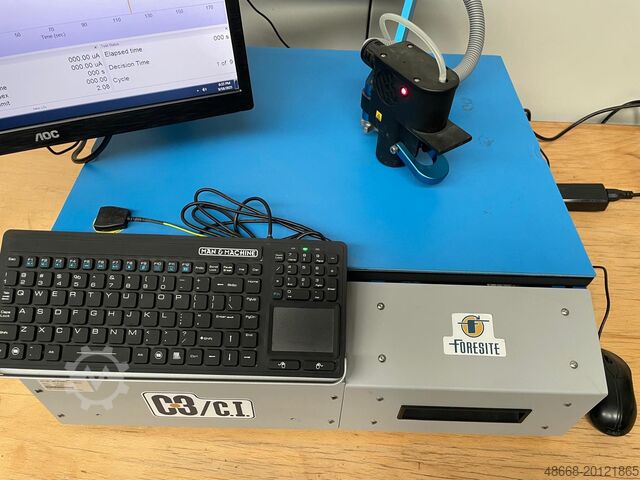

Critical Cleanliness Control Tester

ForesiteC3 / C.I.

Call

Condition: ready for operation (used), Foresite C3 / C.I. Critical Cleanliness Control Tester Analytics Technology

Year of manufacture: 2011

The C3 is unique among electronics cleanliness quality testers. It remains the only tester on the market that indicates whether a specific, critical area of a PCBA (Printed Circuit Board Assembly) is clean.

Simply select the components and/or circuit areas most sensitive and vulnerable to contamination and/or reliability issues, and test a small area (0.1 in²). The C3 quickly provides feedback as to whether potentially detrimental residues, often caused by manufacturing processes, are present.

Once the critical areas to be tested have been identified, the operator simply inserts a new disposable test cell into the vapor head and manually positions the head via the articulated arm over the test area. The weight of the arm and vapor head seals the test cell on the test surface. The operator then starts the automated testing sequence. Within 7-10 minutes, the operator knows whether the tested product area meets cleanliness standards. The C3 can be used directly in the production area.

At the end of the test, the cell can be easily removed using the cell ejector on the head. The test sample in the cell, efficiently extracted from the small test area using steam, can undergo further analysis to identify specific contaminants and their concentrations. The entire test is simple and straightforward for the operator, with results not dependent on operator skill. The use of Pro-Site single-use test cells and extraction solution prevents cross-contamination of samples.

You are welcome to arrange an inspection.

We can also organize cost-effective shipping for you!

You will receive a proper invoice.

For foreign customers, a net invoice can also be provided, provided a valid VAT ID number is available.

Subject to prior sale.

Visit our shop and take a look at our other offerings as well.

Brand names and trademarks mentioned are the property of their respective owners and are used solely for identification and product description purposes.

Bledpfx Afjxhckljhjc

Technical data deviations and errors in the description of the item may occur and are subject to change.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Babenhausen

Babenhausen

6,860 km

Dishwasher

MilbrandtR-Line NEU

Call

Condition: new, Year of construction: 2025, functionality: fully functional, machine/vehicle number: 2025, warranty duration: 12 months, input voltage: 400 V, DGUV certified until: 12/2026, total length: 700 mm, total width: 600 mm, total height: 850 mm, input frequency: 50 Hz, type of input current: three-phase, power: 6.7 kW (9.11 HP), electrical fuse: 16 A, Dishwasher

Model: R-Line 1500

Quick-ready system

Euronorm 500

2.4 liters of fresh water consumption

7 washing programs with 3 easy

Rinse aid and detergent dosing pump

extra deep interior for sheets / tubs 600 x 400 mm

DGUV V3 checked

Sequence / drain pump

Connection: 400 V, 6.7 kW, 16A-CEE plug

Dimensions: 600 x 700 x 850 mm, WxDxH

with warranty

Included accessories:

1 plate basket

1 universal basket

Bodpjfffhwofx Afhelc

1 cutlery basket

Inlet and outlet hoses

Listing

Duxford

Duxford

7,469 km

Bio-Rad PowerPac 200 DC Power supply

Bio-RadPowerPac 200

Call

Condition: used, This listing is for the Bio-Rad PowerPac 200 DC power supply

The unit is in full working condition and is ready for immediate use

Bljdpsyfh Apsfx Afhjc

The Bio-Rad PowerPac 200 is a DC power supply designed primarily for gel electrophoresis and blotting applications in molecular biology and biochemistry labs. It provides stable, controllable electrical power to electrophoresis tanks used for separating DNA, RNA, or proteins

Listing

Reggio Calabria

Reggio Calabria

6,319 km

Paper cutting machine

Polar MohrMohr 80 net

Call

Condition: used, Year of construction: 2012, operating hours: 10,000 h, functionality: fully functional, cutting width (max.): 800 mm, insertion depth: 800 mm, insertion height: 150 mm, cutting length (max.): 800 mm, overall weight: 500 kg, type of input current: three-phase, total width: 160 mm, total length: 200 mm, input voltage: 400 V, Equipment: documentation/manual, safety light barrier, The MOHR 80 cutter is engineered for single-shift operation and features a precise, gentle swing cut actuated hydraulically, allowing the dwell time of the knife at the lower dead point to be tailored to the material. The ultra-smooth stainless-steel table, fitted with air jets, makes material handling effortless. Clamping pressure is infinitely adjustable via a scaled rotary knob to accommodate a wide range of cutting materials. High-visibility LEDs clearly indicate the cutting line for the operator.

Operation is carried out through an ergonomically positioned 18.5’’ touch-screen display. The machine can store up to 1,998 cutting programs for rapid recall and flexible adaptation of recurring sequences. Integrated into a digital workflow, cutting data can be received directly from pre-press into Compucut® in ppf- or jdf-format, which then automatically generates the appropriate cutting program. A barcode reader enables automatic program retrieval and execution, effectively reducing set-up times to nearly zero. Process visualization graphically displays material handling, significantly minimizing error risk. To further optimize cutting quality, the pre-clamping time can be adjusted based on the material being processed.

Key features:

- Barcode reader for automatic creation and loading of assigned cutting programs via Compucut®

Bsdpfx Aexwnxgefhjlc

- Process visualization for graphical representation of material handling, minimizing error risk

- Rigid machine frame engineered for optimal stability, maximizing absorption of cutting forces and ensuring superior cutting accuracy

- Minimal maintenance requirements thanks to the use of advanced materials

Technical specifications:

- Cutting width: 800 mm (31.49 in)

- Feeding depth: 800 mm (31.49 in)

- Maximum feeding height: 100 mm (3.93 in)

- Clamping pressure: minimum 180 daN (397 lbs), maximum 2,700 daN (5,953 lbs)

- Backgauge speed (return): up to 130 mm/sec (5.12 in/sec)

- Minimum automatic cut without false plate: 15 mm (0.60 in)

- Minimum automatic cut with false plate: 50 mm (1.96 in)

- Dimensions (W × D × H): 1,430 × 1,970 × 1,500 mm (56.29 × 77.55 × 59.05 in)

Listing

Duxford

Duxford

7,469 km

Tecan Infinate 200 Pro Microplate Reader

Tecan Infinate200 Pro

Call

Condition: used, This listing is for the Tecan Infinate 200 Pro Microplate Reader

Bljdpfxeydqmzj Afhec

The unit is in full working condition and is ready for immediate use

The Tecan Infinite 200 PRO is a multimode microplate reader — a laboratory instrument used to measure the intensity of light in biological and chemical assays placed in microplates (usually with 96, 384, or more wells). It’s widely used in life sciences research, clinical labs and drug discovery for quantitative analysis of samples

Typical Uses

Laboratories use this type of plate reader to:

• Quantify DNA/RNA or protein concentrations

• Run immunoassays like ELISA

• Perform drug screening assays

• Read fluorescence or luminescence signals from reporter gene assays

• Monitor cell viability or enzyme activity

Listing

Altenstadt

Altenstadt

6,772 km

Bridge saw

Bombieri&VenturiFSBV 500 MG

Call

Condition: used, Year of construction: 2001, functionality: fully functional, travel distance X-axis: 3,150 mm, travel distance Y-axis: 3,600 mm, travel distance Z-axis: 150 mm, table width: 1,800 mm, table length: 3,200 mm, Bridge saw with tilting table

Sawing up to 15 cm height possible with automatic lowering and manual mode

Automatic cutting sequence with shut-off

German-language display operation and fault analysis

Manual rotary table with digital angle display

Tilting table with plug-in forks

Mechanical tilting of the saw head possible

500 mm saw blade diameter

Bodpfx Ajxiw Twsfhjlc

Listing

Warstein

Warstein

6,907 km

Vertical machining center

StarragCWK 400D

Call

Condition: good (used), Year of construction: 2005, operating hours: 32,099 h, functionality: fully functional, travel distance X-axis: 625 mm, travel distance Y-axis: 650 mm, travel distance Z-axis: 650 mm, controller manufacturer: Siemens, controller model: Sinumerik 840D, total length: 5,800 mm, total width: 4,800 mm, table width: 400 mm, table length: 500 mm, overall weight: 12,800 kg, spindle speed (max.): 10,000 rpm, operating hours of spindle: 3,648 h, coolant supply: 50 bar, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, For sale is a 4-axis horizontal machining center from the manufacturer Starrag.

The machine is used, has been regularly maintained, and is in fully functional condition.

Machine Details

- Manufacturer: Starrag

- Model: CWK 400D

- Year of manufacture: 2005

- Operating hours: 32,099

- Control: Siemens Sinumerik 840D

- Machine weight: 12,800 kg

- Footprint (LxW): 5.8 x 4.8 m

Technical Data

Travel paths:

- X = 625 mm

- Y = 650 mm

- Z = 650 mm

- B axis: 360° (0.001° increments) / 100 rpm

- Spindle speed: 50 – 10,000 rpm (stepless)

- Motor power: 24 kW / 37 kW

- Torque: 250 Nm / 350 Nm

Table & Pallets

- 2 pallets, each 500 x 400 mm

- T-slots to DIN 55201

- Load capacity: 400 kg

- Pallet changer included (changeover time 8 s / 5 s)

Tool Data

- Interface: DIN 69893-HSK-A63

- Chain magazine with 60 tool positions

- Tool diameter: 80 mm (up to 160 mm with adjacent pockets free)

- Max. tool length: 350 mm

- Max. tool weight: 10 kg

- Total tool weight: 200 kg

Equipment & Extras

- Coolant system (emulsion, internal & external supply, approx. 1100 L)

- Knoll coolant unit with fleece filter (30, 40, 50 bar)

- Measuring probe: Renishaw

- Tool breakage monitoring in magazine

- Chip conveyor

- Flood wash, paper band filter, cleaning gun at setup station

- Fully enclosed working area to UVV safety standards

- Pallet sequence mode

- Network connectivity, Ethernet interface

Bsdpsx Ib T Ijfx Afhjlc

- Technical documentation & layout plan included

Maintenance

- Carried out regularly

- Machine is fully functional

All details have been prepared to the best of our knowledge and belief. Subject to changes, errors, and prior sale.

Listing

Warstein

Warstein

6,907 km

Vertical machining center

DMG MoriDMC 60H hi-dyn

Call

Condition: good (used), Year of construction: 2000, operating hours: 48,804 h, functionality: fully functional, travel distance X-axis: 600 mm, travel distance Y-axis: 560 mm, travel distance Z-axis: 560 mm, controller manufacturer: Siemens, controller model: Sinumerik 840D, total length: 7,000 mm, total width: 5,000 mm, table width: 400 mm, table length: 500 mm, spindle speed (max.): 8,000 rpm, operating hours of spindle: 23,574 h, coolant supply: 50 bar, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, Very well-maintained 4-axis machining center from precision manufacturing. The machine has been serviced regularly, is immediately ready for operation, and comes with a pallet changer and extensive accessories. Ideally suited for tool and mold making or series production.

Technical Specifications

-Travel distances: X 600 mm / Y 560 mm / Z 560 mm

-B-axis: 360° x 0.001° (60 rpm)

-Spindle speed: 0 – 8000 rpm (stepless)

-Control: Siemens Sinumerik 840D

-Table size: 6 pallets, each 500 x 400 mm

-Table load: 350 kg

-Working feed: 1 – 60,000 mm/min

-Rapid traverse: 60 m/min

Bedpfx Aex Icyvefholc

Tool & Magazine

-Tool holder: DIN 69871-SK40

-Chain magazine with 90 positions

-Max. tool diameter: 80 mm

-Max. tool length: 350 mm

-Max. tool weight: 10 kg

-Max. total magazine weight: 450 kg

-Tool change time: 5 sec

-Pallet change time: 6 sec

Machine Requirements & Dimensions

-Motor power: 13 kW / 20 kW

-Torque: 124 / 191 Nm

-Total power requirement: 20 kW

-Machine weight: approx. 16,000 kg

-Required floor space (LxW): 7 x 5 m

Equipment & Accessories

-Coolant system approx. 1100 L (internal & external)

-Knoll cooling unit with drum filter (30/40/50 bar via M-command)

-Chip conveyor

-Tool measurement: Renishaw probe

-Tool breakage detection in the machining area

-Pallet storage (4 positions)

-Pallet sequence operation

-Enclosed work area in accordance with UVV

-Network capability

-Technical documentation & installation layout available

Components Renewed

-Hydraulic system motor & pump replaced

-Some hydraulic and pneumatic hoses replaced

-Control cabinet LT module exchanged

-Drum of Knoll system replaced

Operating Hours / Run Times

- Power-on hours approx. 48,804 h (counter runs when the machine is switched on, including during setup, maintenance, or idle times)

- Spindle run time total 23,574 h

Special Features

- Machine live, immediately ready for use

- Inspection possible any time by appointment

- No dealer sale – machine comes directly from production

- Technically inspected, no known defects

- Assistance with disassembly, loading, and transport possible (for an additional charge)

All information has been provided to the best of our knowledge and belief. Subject to alterations, errors, and prior sale.

Listing

Bocholt

Bocholt

7,030 km

Hydraulic plate shears

AmadaGX II 630

Call

Condition: excellent (used), functionality: fully functional, Year of construction: 2017, Amada Hydraulic Guillotine Shear Type GX II 630

Working width: 3050 mm

Max. sheet thickness: 6.35 mm

Robust CNC electro-hydraulic guillotine shear

AMADA CNC touch control, located front left ("GP 37W2")

Machine control system including information display

Main display with 4 operating panels

Bjdpfx Afoxwmycshslc

Control/operation of all machine functions

Up to 50 cutting programs, each with up to 15 sequences

CNC electromechanical backgauge

Travel speed: 100 mm/sec

CNC electro-hydraulic cutting angle adjustment

CNC electro-hydraulic blade gap adjustment

Sight device & cutting line illumination for viewing the scribe line

Shearing according to optical scribe mark

Manually adjustable table support plates including ball rollers

Grip recesses in the front support table

2x movable foot switches

Operating manual and circuit diagrams included

Listing

Ortenburg

Ortenburg

6,548 km

Edge banding machine

Brandt HomagKDF 1650 Highflex

Call

Condition: excellent (used), Year of construction: 2010, operating hours: 2,560 h, functionality: fully functional, total length: 5,760 mm, workpiece height (max.): 60 mm, edge thickness (max.): 12 mm, height adjustment type: electric, plate height: 60 mm, Brandt 1650 Highflex with Return Conveyor and PU Glue Box, Excellent Condition

Year of manufacture: 2010

Operating hours: 2,587 h

Total edge length processed: 216,000 m

Maximum edging thickness: 12 mm

Maximum panel thickness: 60 mm

Maximum thickness of roll material: 3 mm

Minimum workpiece width: 70 mm

Maximum feed speed: 18 m/min

Feed speed: infinitely variable

Height adjustment: motorized

Glue system: granulate

Pre-melter

BRANDT glue system QUICKMELT KD

2 x PU glue pots

Strip magazine

Jointing milling unit

End trimming unit with 2 motors

Flush/radius/bevel stations: 1

Corner rounding unit with 2 motors

Scraper unit

Profile scraper, flat scraper

Buffing unit

Bsdpfxsvnwf Uj Afhelc

Aggregates sequenced

NC axis/axes

Version: right-handed machine

Machine length: 5,760 mm

Conformity mark: CE

Return conveyor: Ligmatech Boomerang

PU glue box

Still in operation, inspection recommended, available by arrangement

No warranty

Pick-up only, forklift available

Net price edgebander: €26,000 plus VAT

Net price panel return conveyor: €7,000 plus VAT

Machines can also be purchased separately

Price negotiable

Listing

Janville

Janville

7,382 km

Micro doser

MCPI Fine dosingOPTI-FEEDER FD - SPA - classe 2A

Call

Condition: used, Year of construction: 2014, Manufacturer : MCPI Fine dosing

Model: OPTI-FEEDER FD - SPA - class 2A

Year : 2014

Type : Micro dosing machine / Precision dosing machine

Type of product : powder / granules, dry form

Type of dosing : weight by batch in gravimetric mode

Weight measurement chain : Weighing scale / Precision weigher

Filling of doser storage hopper: Manual

Electronic weighing control and management

Extractor outlet cross-section: 80 mm

Dosing sequence: 3 dosing speeds (coarse, medium and fine) to optimise the precision / dosing speed ratio

Dosing quality monitoring (+ and - tolerance interval)

Scale measurement resolution: 10 mg (0.01 g)

Minimum dose (estimate): 250 mg

Maximum dose (estimate): 500 g

Memory for 800 different dosing recipes

Trigger: foot pedal

Results retrieved on USB key, and analysed in Excel.

Control unit: Unit built to CE standards. All control and command elements are integrated into this box (controller, PLC, drive, safety devices, switches, etc.). Power supply: 220V - single-phase

Doser / control box connection: direct

Materials in contact with the ingredient : 304L electro-polished stainless steel.

Bledjx R Dh Hjpfx Afhsc

Construction according to GMP rules

Machine dimensions: 95 x 75 x H 170 cm

Documentation available

Listing

Janville

Janville

7,382 km

Micro dosing unit

MCPI Fine dosingOPTI-FEEDER FD - SPA - classe 2A

Call

Condition: used, Year of construction: 2014, Manufacturer : MCPI Fine dosing

Model: OPTI-FEEDER FD - SPA - class 2A

Year : 2014

Type : Micro dosing machine / Precision dosing machine

Type of product : powder / granules, dry form

Type of dosing : weight by batch in gravimetric mode

Weight measurement chain : Weighing scale / Precision weigher

Hopper: 2 litres

Filling of doser storage hopper: Manual

Electronic weighing control and management

Extractor outlet cross-section: 80 mm

Dosing sequence: 3 dosing speeds (coarse, medium and fine) to optimise the precision / dosing speed ratio

Dosing quality monitoring (+ and - tolerance interval)

Scale measurement resolution: 10 mg (0.01 g)

Minimum dose (estimate): 250 mg

Maximum dose (estimate): 500 g

Memory for 800 different dosing recipes

Trigger: hand sensor

Results retrieved on USB key, and analysed in Excel.

Control unit: Unit built to CE standards. All control and command elements are integrated into this box (controller, PLC, drive, safety devices, switches, etc.). Power supply: 220V - single-phase

Doser / control box connection: direct

Materials in contact with the ingredient : 304L electro-polished stainless steel.

Construction according to GMP rules

Bsdpfx Afex R Df Ssholc

Manual electric screwdriver

Machine dimensions: 95 x 75 x H 170 cm

Documentation available

Listing

Hungary

Hungary

6,062 km

Press Brake

MetallkraftGBP 31175

Call

Year of construction: 2022, condition: ready for operation (used), This Metallkraft GBP 31175 press brake was manufactured in 2022. It features a CNC-controlled DELEM DA-58T controller for precise bending sequence calculations and programming. The machine boasts a pressing force of 175 tons and a bending speed of 10 mm/s, with a motor power of 18.5 kW. It includes Italian-made tooling and Fiessler safety lasers for enhanced operation safety. Contact us for more information about this machine.

Blsdpfex D Rphsx Afhjc

Application Types

Bending

Listing

Bydgoszcz

Bydgoszcz

6,269 km

Press Brake 200x3200 DA-58T

OtinusPBO-3220-CNC Delem DA-58T

Call

Condition: new, Year of construction: 2024, Hydraulic press brake PBO-3220-CNC Delem DA-58T

Specifications

- Nominal pressure: 2000 kN

- Max working length 3200 mm

- Throat depth: 320 mm

- Max stroke: 200 mm

- Daylight: 480 mm

- Distance between side frames: 2600 mm

- Max backgauge distance: 600 mm

- Nominal motor power: 15.0 kW

- Length: 3300 mm

- Width: 1800 mm

- Height: 2900 mm

Bsdpfxsipxzpe Afhslc

- Weight: 10500.0 kg

Tools

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): servo motor

- Ram control (Y-axis): servo motor

- Finger height adjustment (R axis): manual

- Type of punch holder: AMADA quick-action clamping

Delem DA-58T controller

- Advanced operator support based on algorithms

- Advanced, graphic simulation of bending sequences

- Operator prompts included

- Algorithms to shorten the production process

- Automatic calculation of crowning

Optional extra - Manual crowning

So that you are always sure that the workpiece will have the same angle along its entire length.

Optional extra - Automatic crowning

Enables the controller to take control over crowning, thus, ensuring that the setting value is always perfectly matched to the needs.

OCS - Oil Cooling System

Oil Cooling System guarantees the stability of the machine's operating parameters even after long, continuous operation.

Assistance by a specialist

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Bydgoszcz

Bydgoszcz

6,270 km

Press Brake 200x4000 DA-58T

OtinusPBO-4020-CNC Delem DA-58T

Call

Condition: new, Year of construction: 2024, Many of our machines are available from stock. Call and ask to find out more.

Hydraulic press brake PBO-4020-CNC Delem DA-58T

Specifications

- Nominal pressure: 2000 kN

Blsdpfx Afjtizayjhjc

- Max working length 4000 mm

- Throat depth: 320 mm

- Max stroke: 200 mm

- Daylight: 480 mm

- Distance between side frames: 3200 mm

- Max backgauge distance: 600 mm

- Nominal motor power: 15.0 kW

- Length: 4100 mm

- Width: 1800 mm

- Height: 2800 mm

- Weight: 13700.0 kg

Tools

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): servo motor

- Ram control (Y-axis): servo motor

- Finger height adjustment (R axis): manual

- Type of punch holder: AMADA quick-action clamping

Delem DA-58T controller

- Advanced operator support based on algorithms

- Advanced, graphic simulation of bending sequences

- Operator prompts included

- Algorithms to shorten the production process

- Automatic calculation of crowning

Optional extra - Manual crowning

So that you are always sure that the workpiece will have the same angle along its entire length.

Optional extra - Automatic crowning

Enables the controller to take control over crowning, thus, ensuring that the setting value is always perfectly matched to the needs.

OCS - Oil Cooling System

Oil Cooling System guarantees the stability of the machine's operating parameters even after long, continuous operation.

Assistance by a specialist

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Bydgoszcz

Bydgoszcz

6,270 km

PRESS BRAKE 80X2500 DA58T

OtinusPBO-2508-CNC Delem DA-58T

Call

Condition: new, Year of construction: 2024, Attention!! Special Offer!!

Warranty inspection free of charge—only for Customers who have taken part in the demonstration at the machine showroom in Bydgoszcz.

A part of our machines is available IMMEDIATELTY.

Hydraulic press brake PBO-2508-CNC Delem DA-58T

Specifications

- Maximum bending thickness (S235): up to 4.0 mm

- Nominal bending force: 800 kN

- Maximum bending length: 2500 mm

- Throat depth: 250 mm

- Maximum stroke: 120 mm

- Daylight: 385 mm

Bledpfx Afjiumyzohsc

- Distance between side frames: 2000 mm

- Backgauge travel distance: 600 mm

- Motor power output: 5.5 kW

- Approaching speed: 0 kW

- Length: 2600 mm

- Width: 1450 mm

- Height: 2300 mm

- Weight: 4800.0 kg

Tools

- Front supports: 2 pcs.

- Backgauge drive (travel along the X-axis): servo motor

- Ram drive (travel along the Y-axis): servo motor

- Backgauge fingers positioning (R-axis): manual

- Punch quick change tooling system form AMADA

DA-58T control

- One-click program generation

- Advanced operator support based on algorithms

- Advanced graphic simulation of bending sequences

- Included prompts for the operator

- Algorithms to shorten the production process

- Automatic crowning calculation

- High-resolution TFT touchscreen

- USB interface

Top quality components

- Rexroth hydraulic valve

- Schneider electrical components

- Omron and Schneider safety circuit parts.

Steel hydraulic line tubings

Hydraulic lines made of steel instead of rubber reduce the risk of future leaks.

Ergonomics

The operator can work freely throughout the machine's working area thanks to the mobile foot switch and the controller on the swivel arm. Additional LED lighting ensures a comfortable view of the workpieces in any situation.

Safety

We attach great importance to the safety of our Clients and their employees; therefore our press brakes are equipped with visible safety labels, side guards, rear safety doors, easily accessible safety switches and light curtains that protect the operator against inserting their hands between the upper and lower dies.

The machines comes with carefully prepared instructions manual.

The machine has a CE marking and EU declaration of conformity.

Oil cooling system

The Oil Cooling System guarantees the stability of the machine's performance even after long, continuous operation.

Within the service, our technicians may:

- Specify the bending steps for intricate parts.

- Advise on material and gas selection

- Assist in the selection of operating parameters for different materials

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Bydgoszcz

Bydgoszcz

6,269 km

Press Brake 125x3200 DA-58T

OtinusPBO-3212-CNC Delem DA-58T

Call

Condition: new, Year of construction: 2024, Hydraulic press brake PBO-3212-CNC Delem DA-58T

Specifications

- Nominal pressure: 1250 kN

- Max working length 3200 mm

- Throat depth: 320 mm

- Max stroke: 120 mm

- Daylight: 390 mm

- Distance between side frames: 2600 mm

- Max backgauge distance: 600 mm

- Nominal motor power: 7.5 kW

- Length: 3870 mm

- Width: 1550 mm

Blodpsgi Dkyjfx Afhjc

- Height: 2400 mm

- Weight: 6600.0 kg

Tools

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): servo motor

- Ram control (Y-axis): servo motor

- Finger height adjustment (R axis): manual

- Type of punch holder: AMADA quick-action clamping

Delem DA-58T controller

- Advanced operator support based on algorithms

- Advanced, graphic simulation of bending sequences

- Operator prompts included

- Algorithms to shorten the production process

- Automatic calculation of crowning

Optional extra - Manual crowning

So that you are always sure that the workpiece will have the same angle along its entire length.

Optional extra - Automatic crowning

Enables the controller to take control over crowning, thus, ensuring that the setting value is always perfectly matched to the needs.

OCS - Oil Cooling System

Oil Cooling System guarantees the stability of the machine's operating parameters even after long, continuous operation.

Assistance by a specialist

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Bydgoszcz

Bydgoszcz

6,269 km

Press Brake 160x3200 DA-58T

OtinusPBO-3216-CNC Delem DA-58T

Call

Condition: new, Year of construction: 2024, Hydraulic press brake PBO-3216-CNC Delem DA-58T

Specifications

- Nominal pressure: 1600 kN

- Max working length 3200 mm

- Throat depth: 320 mm

- Max stroke: 180 mm

- Daylight: 455 mm

- Distance between side frames: 2600 mm

- Max backgauge distance: 600 mm

- Nominal motor power: 11.0 kW

- Length: 3300 mm

- Width: 1650 mm

- Height: 2500 mm

- Weight: 8700.0 kg

Tools

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): servo motor

- Ram control (Y-axis): servo motor

- Finger height adjustment (R axis): manual

- Type of punch holder: AMADA quick-action clamping

Delem DA-58T controller

- Advanced operator support based on algorithms

- Advanced, graphic simulation of bending sequences

- Operator prompts included

- Algorithms to shorten the production process

- Automatic calculation of crowning

Optional extra - Manual crowning

So that you are always sure that the workpiece will have the same angle along its entire length.

Bljdpfogih Iusx Afhjc

Optional extra - Automatic crowning

Enables the controller to take control over crowning, thus, ensuring that the setting value is always perfectly matched to the needs.

OCS - Oil Cooling System

Oil Cooling System guarantees the stability of the machine's operating parameters even after long, continuous operation.

Assistance by a specialist

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Bydgoszcz

Bydgoszcz

6,270 km

Press Brake 160x4000 DA-58T

OtinusPBO-4016-CNC Delem DA-58T

Call

Condition: new, Year of construction: 2024, Many of our machines are available from stock. Call and ask to find out more.

Hydraulic press brake PBO-4016-CNC Delem DA-58T

Specifications

- Max working thickness (S235): up to 8.0 mm

- Nominal pressure: 1600 kN

- Max working length 4000 mm

- Throat depth: 320 mm

- Max stroke: 180 mm

- Daylight: 455 mm

- Distance between side frames: 3200 mm

- Max backgauge distance: 600 mm

Blsdpfstizavox Afhoc

- Nominal motor power: 15.0 kW

- Length: 4100 mm

- Width: 1650 mm

- Height: 2600 mm

- Weight: 10700.0 kg

Tools

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): servo motor

- Ram control (Y-axis): servo motor

- Finger height adjustment (R axis): manual

- Type of punch holder: AMADA quick-action clamping

Delem DA-58T controller

- Advanced operator support based on algorithms

- Advanced, graphic simulation of bending sequences

- Operator prompts included

- Algorithms to shorten the production process

- Automatic calculation of crowning

Optional extra - Manual crowning

So that you are always sure that the workpiece will have the same angle along its entire length.

Optional extra - Automatic crowning

Enables the controller to take control over crowning, thus, ensuring that the setting value is always perfectly matched to the needs.

OCS - Oil Cooling System

Oil Cooling System guarantees the stability of the machine's operating parameters even after long, continuous operation.

Assistance by a specialist

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Trust Seal

Dealers certified through Machineseeker

Listing

Bydgoszcz

Bydgoszcz

6,270 km

Press Brake 250x3200 DA-58T

OtinusPBO-3225-CNC Delem DA-58T

Call

Condition: new, Year of construction: 2024, Hydraulic press brake PBO-3225-CNC Delem DA-58T

Specifications

- Max working thickness (S235): up to 10.0 mm

- Nominal pressure: 2500 kN

- Max working length 3200 mm

- Throat depth: 400 mm

- Max stroke: 250 mm

- Daylight: 535 mm

- Distance between side frames: 2500 mm

Bsdpfx Aeium Hkofhelc

- Max backgauge distance: 600 mm

- Nominal motor power: 18.5 kW

- Length: 3300 mm

- Width: 1850 mm

- Height: 2900 mm

- Weight: 11600.0 kg

Tools

- Front supports: 2 pcs

- Backgauge distance regulation (X-axis): servo motor

- Ram control (Y-axis): servo motor

- Finger height adjustment (R axis): manual

- Type of punch holder: AMADA quick-action clamping

Delem DA-58T controller

- Advanced operator support based on algorithms

- Advanced, graphic simulation of bending sequences

- Operator prompts included

- Algorithms to shorten the production process

- Automatic calculation of crowning

Optional extra - Manual crowning

So that you are always sure that the workpiece will have the same angle along its entire length.

Optional extra - Automatic crowning

Enables the controller to take control over crowning, thus, ensuring that the setting value is always perfectly matched to the needs.

OCS - Oil Cooling System

Oil Cooling System guarantees the stability of the machine's operating parameters even after long, continuous operation.

Assistance by a specialist

We make sure to stay in constant touch with our Clients. This is why we add a time package of tech support hours for Otinus Professional Assistance to each machine purchased.

See and test the machine

Join us for a one-of-a-kind demonstration where a qualified Otinus technician will show you the full functionality of the machine.

In addition, you will be able to try out how the device will perform against your needs as you can provide technical drawings and sample material.

Included in the machine price

2-day training including installation of the machine

- 1st day (up to 8 hours) - installation of the machine and learning to use the controller.

- 2nd day (up to 8 hours) - independent work on the machine under the supervision of our technician with the possibility of programming specific parts manufactured by the Client.

Telephone consultation with a specialist

- 7.30 a.m. to 9 p.m. (Mon-Sat) - package of 8 hours to be used within 12 months

- Free lending of transport rolls and two lifting jacks for easier positioning of the machine at Clients' facilities. The rollers and jack will be delivered after prior notification (no less than 7 days before delivery of the machine).

Terms of cooperation

- 24 month warranty

- The machine is brand new

- Warranty and post-warranty service provided by the seller

- The Client is responsible for the machine during unloading and transporting on-site

Listing

Radom

Radom

6,026 km

Automatic perforator

Kugler 340-2RAutomatic perforator

Call

Condition: good (used), Automatic perforator Kugler 340-2R

Device in very good condition.

Includes perforation tool 3:1 round hole and additional tools.

Manufacturer description:

Perforation device with a working width of up to 340 mm

Device adapted for continuous operation and high loads

Unique „Two-finger” system ensures excellent reception of sheets of various grammages

Two-shelf feeder enabling continuous operation

After perforation, sheets rotate around a special drum, thanks to which the correct sequence of pages is maintained at the receiving station

Possibility of using two-part strips enabling perforation of both books and calendars

Perforation up to 3 mm in one cycle

Quick and easy replacement of perforation strips

Possibility of using strips with / without a recess for the hanger.

There is a shaker on the delivery.

Maximum working width. 340 mm

Format / Dimensions min. 120x105mm

Blodpfewt Stvox Afhsc

Format / Dimensions max. 340x340mm

Maximum cutting thickness. 3mm

Mechanical cycles per minute 80-100 cycles

Power supply 380V

Weight 1580kg

Listing

Bitburg

Bitburg

7,034 km

Wide planer

MartinT45 - sofort verfügbar -

Call

Condition: new, Year of construction: 2024, Martin T 45 thickness planer with XPLANE cutterblock

The T45 thicknessing machine offers ideal conditions for modern production:

It delivers cleanly planed surfaces, is quick and easy to operate and works extremely quietly.

and works extremely quietly. The standard electronic control system makes

Thanks to 99 storable planing dimensions, setting the planing height is so easy that even the

the first workpiece fits perfectly. Of course, the

thicknessing table can also be moved at the simple press of a button, or can be incremented by 0.1 mm.

upwards. The switching elements of the feed control are also within easy reach.

reach. The heavy, vibration-damping composite stand with the high-quality

the high-quality bearing-mounted planing shaft guarantees excellent surfaces. Thanks to the sound-insulating

construction, you can work quietly even in the standard version.

- Planing width: 630 mm

- Weight: approx. 1,200 - 1,400 kg

- Planing height: 2.8 - 300 mm

- Table length: 1,260 mm

- Workpiece length min.: 270 mm

Bedpfx Afoqlck Nsholc

- Speed: 5,000 rpm

- Operation: 1-axis control for planing dimension, max. 99 values can be stored, 49 of which can be used for a freely programmable planing sequence; button for manual quick and fine adjustment of planing thickness according to digital display, push button for cutterblock start and stop, integrated operating hours counter

- Cutterblock: Xplane solid steel cutterblock

Cutterblock with 3 spiral rows of knives (33 cambered hard metal knives per row), delivery includes full set of knives and a Torx T20 T-wrench; shaft speed 6,000 rpm included;

The emission sound pressure level LpA during processing is reduced by 10 dB(A)

- Thicknessing table: Electric thicknessing table adjustment with fine adjustment, travel speed 10 mm/s, mounted on 4 support spindles to prevent tilting, table surface precision-planed

- Feed: 2 speeds 6 / 12 m/min, can also be selected electrically during planing, large rubber feed rollers Ø 85 mm to compensate for different thicknesses of wood, rubber rollers are gentle on the material and self-cleaning, easy roller change; link pressure beam at the infeed

- Suction system: Swivel-up, split hood with chip extraction nozzle Ø 160 mm, can be connected optionally on the left / right (in special cases on both sides); minimum extraction air volume: 27 m³/min. at 20 m/s

- Maintenance device: Central lubrication strip for oil lubrication points; bearing / cutter shaft lubrication via nipple

- Accessories: 1 grease gun, filled with long-life grease

1 oil gun

1 open-end wrench

1 tool for blade change

1 pair of blind knives 640 mm

2 pairs of TERSA reversible knives 640 mm CV

- Emission values: Emission sound pressure level at the workplace LpA according to DIN EN ISO 11202 [dB(A)]

Idle noise (without extraction) P1 65

Idle noise (w. extraction) P1 77

Operating noise (without extraction) P2 65

Operating noise (with extraction) P2 78

Sound power level LWA according to DIN EN ISO 3746 [dB(A)]

Idle noise (without extraction) 84

Operating noise (with extraction) 90

Dust emission Low dust emission according to DGUV 209-044 / BGI 739-1

Location: ex stock 54634 Bitburg

- immediately available -

Listing

Bitburg

Bitburg

7,034 km

Wide planer

MartinT45 - sofort verfügbar -

Call

Condition: new, Year of construction: 2024, Martin T 45 thickness planer with Tersa cutterblock

The T45 thicknessing machine offers ideal conditions for modern production:

It delivers cleanly planed surfaces, is quick and easy to operate and works extremely quietly.

and works extremely quietly. The standard electronic control system makes

Thanks to 99 storable planing dimensions, setting the planing height is so easy that even the

Bedpsqlckpsfx Afhjlc

the first workpiece fits perfectly. Of course, the

thicknessing table can also be moved at the simple press of a button, or can be incremented by 0.1 mm.

upwards. The switching elements of the feed control are also within easy reach.

reach. The heavy, vibration-damping composite stand with the high-quality

the high-quality bearing-mounted planing shaft guarantees excellent surfaces. Thanks to the sound-insulating

construction, you can work quietly even in the standard version.

- Planing width: 630 mm

- Weight: approx. 1,200 - 1,400 kg

- Planing height: 2.8 - 300 mm

- Table length: 1,260 mm

- Workpiece length min.: 270 mm

- Speed: 5,000 rpm

- Operation: 1-axis control for planing dimension, max. 99 values can be stored, 49 of which can be used for a freely programmable planing sequence; button for manual quick and fine adjustment of planing thickness according to digital display, push button for cutterblock start and stop, integrated operating hours counter

- Cutterblock: TERSA solid steel cutterblock Z4 Ø 125 mm; incl. blocking for easy cutter change

- Thicknessing table: Electric thicknessing table adjustment with fine adjustment, travel speed 10 mm/s, mounted on 4 support spindles to prevent tilting, finely planed table surface

- Feed: 2 speeds 6 / 12 m/min, can also be selected electrically during planing, large rubber feed rollers Ø 85 mm to compensate for different thicknesses of wood, rubber rollers are gentle on the material and self-cleaning, easy roller change; link pressure beam at infeed

- Suction system: Swivel-up, split hood with chip extraction nozzle Ø 160 mm, can be connected optionally on the left / right (in special cases on both sides); minimum extraction air volume: 27 m³/min. at 20 m/s

- Maintenance device: Central lubrication strip for oil lubrication points; bearing / cutter shaft lubrication via nipple

- Accessories: 1 grease gun, filled with long-life grease

1 oil gun

1 open-end wrench

1 tool for blade change

1 pair of blind knives 640 mm

2 pairs of TERSA reversible knives 640 mm CV

- Emission values: Emission sound pressure level at the workplace LpA according to DIN EN ISO 11202 [dB(A)]

Idle noise (without extraction) P1 65

Idle noise (w. extraction) P1 77

Operating noise (without extraction) P2 65

Operating noise (with extraction) P2 78

Sound power level LWA according to DIN EN ISO 3746 [dB(A)]

Idle noise (without extraction) 84

Operating noise (with extraction) 90

Dust emission Low dust emission according to DGUV 209-044 / BGI 739-1

Location: ex stock 54634 Bitburg

- immediately available -

We make it easier for you to find: "dna sequencer"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Dna Sequencer (472)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month