Used File Paternoster for sale (648)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Baarle-Nassau

Baarle-Nassau

7,144 km

Center lathe

SchaererUD632

Call

Condition: used, Year of construction: 1982, Lathe Schaerer, model UD632

Specifications:

- Working height above floor: 1120 mm

- Centre height above flat bed: 320 mm

- Swing over bed: 660 mm

- Swing over cross slide (short): 450 mm

- Swing over cross slide (long): 420 mm

- Swing in gap: 710 mm

- Drive power: 15 / 22 kW

- Spindle torque: 3000 Nm

- Max. workpiece weight between centres without steadies: 1500 kg

- Max. workpiece weight between centres with one steady rest: 2200 kg

- Bed width: 460 mm

Main spindle:

- Spindle head with centring cone: 55022, size 8

- Front spindle bearing diameter: 120 mm

- Through spindle bore: 72 mm

- In front, taper 1:20: 80 mm

- Internal taper: Morse 5

- Speeds: 1.8 – 2240 rpm

Carriage feeds (number): 3x32

- Longitudinal feed A, 1:1: 0.07 – 1.12 mm/rev

- Longitudinal feed B, 4:1: 0.31 – 4.5 mm/rev

- Longitudinal feed C, 24:1: 1.8 – 28 mm/rev

- Cross feed A, 1:1: 0.035 – 0.56 mm/rev

- Cross feed B, 4:1: 0.16 – 2.24 mm/rev

- Cross feed C, 24:1: 0.9 – 14 mm/rev

- Rapid traverse longitudinal: 5000 mm/min

- Rapid traverse cross: 2500 mm/min

Leadscrew:

- Pitch: 12 mm

- Diameter: 50 mm

Thread cutting:

- Metric threads (number): 3x32

- Metric thread range A: 1 – 12 mm

- Range B: 3.25 – 48 mm

- Range C: 21 – 288 mm

- Inch threads range A: 24 – 15/8 TPI

- Range B: 6 – TPI

- Range C: 1 – 1/12 TPI

- Module threads A: 0.5 – 6 Mod

- B: 2 – 24 Mod

- C: 10.5 – 144 Mod

- DP threads A: 48 – 3 DP

- B: 12 – 1 DP

- C: 1 – DP

Cross slide:

- Width: 310 mm

- Cross slide short: 465 mm

- Cross slide long: 1000 mm

Top slide travel (manual): 150 mm

Top slide travel (automatic): 180 mm

Tailstock:

- Quill diameter: 90 mm

- Quill travel: 200 mm

Weight (standard version): 3460 kg

Year of manufacture: 1982

Special features:

- Machine is in very clean condition

Dcodpjgbd E Dsfx Afpsc

- Double prism under-bed for high precision

- Digital read-out HEIDENHAIN, model ND 780

- Infinitely variable spindle speed!

- 3-jaw chuck FORKARDT

- Automatic lubrication system

- Automatic tool post

- Rapid traverse on all three axes

- Chip guard

- Machine lighting

Delivery conditions:

- Delivery time: ex-stock, subject to prior sale

- Delivery: ex Baarle-Nassau

- Payment: prior to collection

- Prices: net, excl. VAT

Disclaimer: Machinehandel De Leeuw BV cannot be held liable for any discrepancies in the technical data in this offer and the actual machine.

Machinehandel De Leeuw BV specializes in used machines and accessories for the metalworking industry and used paternoster systems from brands such as Kardex, Hanel/Haenel, Electrolux, Bertello, Megamat, Lista, Denocard and automated storage systems like the Kardex Shuttle XP, XPlus and NT systems.

Warehouse: Oordeelsestraat 7b, NL-5111 PA

Mail address: Postbus 294, NL-5110 AG Baarle-Nassau / The Netherlands

Phone:

Mobile Antoine:

VAT no.: NL800103026B01

CoC Tilburg: 18034279

Listing

Baarle-Nassau

Baarle-Nassau

7,144 km

Band saw

KaltenbachHMB 360

Call

Condition: used, Year of construction: 1996, Used Bandsaw Machine Kaltenbach, model HMB 360

Technical specifications:

- Cutting diameter at 90° (round): 305 mm

- Cutting range at 90° (square): 360 x 305 mm

- Cutting range at 45° (round): 265 mm

- Cutting range at 45° (flat): 265 x 305 mm

- Cutting range at 60° (round): 175 mm

- Cutting range at 60° (flat): 175 x 305 mm

- Table height: 700 mm

- Saw blade dimensions: 3830 x 27 x 0.9 mm

- Band speed: 16 – 100 m/min

- Machine dimensions (LxWxH): 2300 x 1450 x 1650 mm

- Total power requirement: 380 V, 1.1 kW

- Approx. weight: 780 kg

- Year of manufacture: 1996

Djdpfsgbd Egex Afpocc

Terms of delivery:

- Delivery time: ex stock, subject to prior sale

- Delivery: ex works Baarle-Nassau

- Payment: before collection

- Prices: net, excluding VAT

- Technical data: subject to change without notice

Machinehandel De Leeuw BV cannot be held liable for any discrepancies between the specifications given in this offer and the actual machine.

About Machinehandel De Leeuw BV:

Machinehandel De Leeuw BV specializes in used machinery and accessories for the metalworking industry, as well as used paternoster systems from brands such as Kardex, Hanel/Haenel, Electrolux, Bertello, Megamat, Lista, Denocard, and automated storage systems like the Kardex Shuttle XP and XPlus systems.

Machinehandel De Leeuw BV

Visit address: Oordeelsestraat 7b, NL-5111 PA

Postal address: P.O. Box 294, NL-5110 AG Baarle-Nassau, Netherlands

Phone:

Mobile Antoine:

VAT No.: NL 801262458B01

Chamber of Commerce Tilburg 18034279

Listing

Nattheim

Nattheim

6,764 km

CNC machining center

SCMZ1 26A

Call

Condition: used, Year of construction: 2011, · Working area: 2,550 x 1,067 mm

· X-Y travel: 2,980 x 1,450 mm

· Z-axis travel length: 150 mm

· Clearance height: 120 mm

Drilling Unit F14:

· Drilling head with 8 + 6 spindles

· 5 individually selectable vertical spindles in X

· 3 individually selectable vertical spindles in Y

· 4 horizontal spindles in X (2+2)

· 2 horizontal spindles in Y (1+1)

· Speed: 4,000 rpm (6,000 rpm available as an option)

· Power: 2.2 kW

· Grid: 32 mm

· Drill holder: M10 with 11 mm positive fit

· Pneumatic feed stroke: 60 mm

Grooving saw unit in "X":

· Integrated in the drilling head

· Grooving saw blade with a maximum diameter of 120 mm

Main milling unit:

· Tool interface HSK 63F

· Speed: 1,500 – 24,000 rpm, infinitely variable via inverter

· Motor power: 6.6 kW (9 HP) from 12,000 rpm (S1)

· Motor power: 7.5 kW (10 HP) from 12,000 rpm (S6)

· Right-/left-hand rotation

· Ceramic bearings

· Prepared for use with angle drives

Tool changer TR10:

Automatic lateral tool changer for 10 tools.

· Number of tool positions: 10

· Maximum tool diameter: 120 mm

· Maximum weight per tool: 4.5 kg

· Maximum total tool weight: 28 kg

A central extraction port collects all processing units into a single connection with D=200 mm. This reduces the required extraction capacity to approx. 3,200 m³/h.

TVF worktable:

The worktable is designed to provide the operator with maximum "freedom of movement." The vacuum quick-clamping system offers maximum flexibility for precise positioning and optimal holding of workpieces.

· 4 TVF supports, L=1100 mm, infinitely adjustable in X

· 12 TVF vacuum cups 120 x 120 mm, infinitely adjustable in Y

· 2 stops in X (1 left / 1 right)

· 1 stop in Y per support (total 4 pcs.)

· Retractable reference stops controlled via CNC

Automatic central lubrication:

The correct amount of lubricating grease is distributed via an electronic CNC control unit (X, Y, Z axes)

Vacuum system (base machine):

· Vacuum pump: 90 m³/h

· Power: 2.2 kW

· Max. negative pressure (at pump): 0.9 bar

PROGRAMMING SYSTEM XILOG PLUS

Dodox Twc Nspfx Afpjcc

Software features:

- Import of DXF files

- Import of ASCII files

- User interface in operator’s native language

Safety devices with bumpers

Machine technical data:

· Total connected load max.: 18 kW

· Recommended fuse: 64 A

· Power supply: 400 V 50-60 Hz

· Compressed air: 6-7 bar

· System pressure (recommended): 8 bar

· Compressed air consumption: 200 Nl/min

· Central extraction port Ø: 200 mm

· Extraction speed: 30 m/sec

· Air consumption (central extraction): 3,200 m³/h

· Negative pressure: 3,000 Pascal

· Weight: approx. 2,500 kg

Remote control of machine functions

6 TVF supports L=1,100 mm and 18 vacuum cups 120x120 mm

Cross lasers for vacuum cup positioning

Two cross lasers mounted on the unit carrier allow for easy positioning of the vacuum cups.

Location: Nattheim

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Bochum

Bochum

6,984 km

5-axis simultaneous machining center

AlzmetallGS1200

Call

Condition: excellent (used), Year of construction: 2017, Machine model: ALZMETALL GS 1200

Year of manufacture: 2017

Technical specifications:

1. Machine concept:

· Gantry design for closed force flow

· All dynamically stressed components made of spheroidal graphite cast iron EN-GJS 500 (GGG50)

2. Working area:

· X-axis travel: 1000 mm

· Y-axis travel: 1200 mm

· Z-axis travel: 800 mm

· Distance spindle–rotary table min./max.: 167 mm / 967 mm

3. Control system:

· Contour control: Heidenhain TNC 640 with digital drive control

· Control panel: rotatable and pivotable

· 19" TFT color flat screen with touch pad

· Hard disk, linear and circular interpolation, helical interpolation, 3D interpolation

· Look-ahead function (1024 blocks)

· Standard drilling and milling cycles, probing cycles

· Parallel operation, file management

· Programming in Heidenhain plain text and DIN/ISO

· Graphical support for free contour programming

· Multiple zero point tables

· Interfaces: 1× V.24/RS-232-C (up to 115 kbit/s), 2× Gigabit Ethernet (1000 Base-T)

4. Lubrication:

· Central grease lubrication for all axis guides and drive systems

· Permanent grease lubrication for the high-frequency motor spindle

· Lubrication interval control via PLC

5. Coolant and chip removal:

· Only coolant with a high mineral oil content allowed

· No synthetic or semi-synthetic agents

· Cooling system designed for water-based agents

· For emulsions: flash point > 140°C

· Fire protection requirements for oil-based agents and flammable materials (e.g. magnesium)

6. Hydraulics/Pneumatics:

· Hydraulics: max. 140 bar, max. 6.8 l/min

· Pneumatics: 2 channels, max. 8 bar, max. 4.8 l/min

7. Accessories/Options (selected items):

· Electronic handwheel HR 510 (portable)

· 3D probing system with infrared transmission (M&H Inprocess, type IPR 40.01)

· Safety foot confirmation switch for setup mode

· Continuous air operation without lubrication interval (max. 10 bar pressure)

· Rinsing hose with spray gun incl. pump

· Preparation for stationary extraction system (2 units, manufacturer Reven)

· Production package C: chip conveyor with coolant tanks, band filter, pumps

· Safety laminated glass window, automatic roof cover

8. Machine enclosure:

· Full enclosure made of sheet steel

9. Table data:

· Max. table load: 2500 kg (balanced)

· Rotary diameter on C around center A-axis: Ø 1220 mm

· Swivel diameter on A around center X-axis: Ø 1240 mm

· Rotary table C-axis below center A-axis: max. 100 mm

10. Tool changer:

· Max. tool weight per chain: 250 kg

Dodeyag Tvspfx Afpjcc

· Chip-to-chip time: approx. 7 s

Reference tool Ø 2/1. DS6, in HSK T100 holder

Listing

Germany

Germany

6,946 km

VITAP K3

VITAPK3

Call

Condition: ready for operation (used), Year of construction: 2023, spindle speed (max.): 3,600 rpm, spindle motor power: 5,000 W, number of axes: 3, This 3-axis VITAP K3 CNC Wood Machining Centre was manufactured in 2023. Consider the opportunity to buy this VITAP K3 CNC Wood Machining Centre. Contact us for more information.

Additional equipment

• 20" LCD TFT monitor

• Industrial PC

Djdsx U Ub Sspfx Afpocc

• WSC user interface with Lister, parametric tools, and parametric setup

• Graphical CAD programming TPA EDI32, basic version

• USB port

• Storage of all files

• Macro programming

• Import of DXF files

• CE compliant

Machine Benefits

Qualitative Machine Benefits

• A showroom machine never used

Technical Machine Benefits

• Feed speed: 25 m/min

• Automatic 4-position tool changer

• Max. Horizontal tool Ø: 12 mm

• Max. Vertical tool Ø: 35 mm

• Motor: 1. 7 kw

• Number of independent vertical spindles: 12 // number of independent horizontal spindles on the x-axis: (2+2)

• Max. Horizontal drilling depth on x and y axes: 35 mm // max. Vertical drilling depth: 43 mm // number of horizontal drilling spindles on the y-axis: (2+2)

• Electro spindle: 5 kw with iso30 taper (rpm 12000–24000)

• Max. Workpiece dimensions: y 1250 mm, z 50 mm

• Min. Workpiece dimensions: x 270 mm, y 150 mm, z 3 mm

Extra Information

Axes: 3 controlled axes (X, Y, Z)

X-Axis: DDT feed system

Y-Axis: Drilling head travel path

Z-Axis: Drilling operations

Optional Upgrades (at Additional Cost):

Tool set for production startup

Tool holder ISO 30 / ER 32

Lubricant cartridges

PC with a more powerful processor

Additional pneumatic upper pressure

Free Nesting System

Barcode scanner

Post-processor for MPR files

Office software license TPA

Front and rear roller support

Narrow part guides

Optional clamp opening for 60 mm thickness

Angle gear options

CAD design software for furniture construction

Listing

Bosnia and Herzegovina

Bosnia and Herzegovina

6,946 km

HAAS UMC-750SS

HAASUMC-750SS

Call

Condition: ready for operation (used), Year of construction: 2021, travel distance X-axis: 762 mm, travel distance Y-axis: 508 mm, travel distance Z-axis: 508 mm, controller manufacturer: HAAS, spindle speed (max.): 12,000 rpm, spindle motor power: 22,400 W, number of axes: 5, This 5-axis HAAS UMC-750SS vertical machining center was manufactured in 2021. Consider the opportunity to buy this HAAS UMC-750SS vertical machining center. Contact us for more information.

Additional equipment

• Coolant tank – 208 liters with mobile cart

Dcsdpfx Afsx U Tizepsc

• Programmable coolant pump (M-code controlled) // Programmable Coolant Nozzle (P-COOL)

• Safe Run – crash and overload detection system

• Control cabinet surge protection

• Voltage fault detection module (EPFDM)

• Second Home Position button

• Remote Jog Handle with 2m cable (RJH-XL)

• Memory lock key-switch

• Rotary axis scales

• Top cover

Machine Benefits

Technical Machine Benefits

• 30+1 tool side-mount tool changer

• Wireless intuitive probing system (wips)

• Broken tool detection (btd)

Extra Information

Media display via M130 (images, videos, PDF on screen)

Standard machine memory: 1 GB

Control Unit

15" color LCD monitor with USB port

Touchscreen control interface

Ethernet interface

HaasConnect remote monitoring

HaasDrop wireless file transfer

WiFi connectivity

Controller

High-speed machining (HSM)

Rigid tapping

Dynamic Work Offsets / Tool Center Point Control (DWO/TCPC)

Macro programming, coordinate rotation & scaling

Listing

Hørning

Hørning

6,828 km

Four-sided planer

KUPERTYP SWT 23 XL - 5

Call

Condition: ready for operation (used), Year of construction: 2010, functionality: fully functional, Table lenght 2000 mm.

Workingwidth: max. 230 mm / min. 18 mm.

Workingheight: max. 150 mm / min. 8 mm

el height adjustable

Dcodpfx Ajxr U Azefpec

Speed 7-36 m/min. 3,7 kw motor, cardan

5 pcs. Ø 40 mm. spindels: b + r + l + t + b (specifikations see file attached

Siemens touchscreen

see all technical features attached file

Listing

Hørning

Hørning

6,828 km

DEP

CMLMOD. STDA 336

Call

Condition: ready for operation (used), Year of construction: 2010, functionality: fully functional, CML - DEP FLEXIBLE LINE FOR WINDOWS ELEEMNTS PRODUCTION AS PER LAYOUT LY-09-087-05 DATED 27/01/2010

01 BELT CONVEYOR 1=4500 mm

02 "L" TRANSFER WITH PVC COATED ROLLERS AND BUFFER

03 DOUBLE END TENONER CML MOD. STDA 336

04 FULL SYSTEM FOR MACHINE CONTROL

SEE TECHNICAL FEATURES ATTACHED PDF-FILE

Dcsdpfx Ajxtaciofpsc

Listing

Burkardroth

Burkardroth

6,786 km

MT1212 threading machine

CoastOneMultitapper 1212

Call

Condition: new, Year of construction: 2025, operating hours: 10 h, functionality: fully functional, machine/vehicle number: MT1212_38, warranty duration: 36 months, Multitapper 1212 automatic threading machine

CoastOne - Made in Finland

New machine

Working area: 1250x1250mm

Dcsdpfx Afjxd U R Nepjc

Thread sizes: M2-M10

Number of spindles: 3 (optional 4)

2x thread cutting; 1x countersink drilling station

Micro lubrication for every spindle / tool station

Control: TC15 touchscreen

Numerical entry, import of punches - NC files

Listing

Burkardroth

Burkardroth

6,786 km

MT1212 threading machine

CoastOneMultitapper 1212

Call

Condition: excellent (used), Year of construction: 2025, operating hours: 100 h, functionality: fully functional, machine/vehicle number: MT1212_2025_28, working range: 1,250 mm, overall weight: 1,400 kg, compressed air connection: 6 bar, total height: 1,610 mm, total length: 2,550 mm, type of input current: AC, warranty duration: 36 months, workpiece weight (max.): 80 kg, table width: 1,250 mm, air pressure: 6 bar, input current: 16 A, table length: 1,250 mm, space requirement height: 1,610 mm, space requirement length: 2,550 mm, space requirement width: 1,770 mm, Equipment: documentation/manual, rotational speed infinitely variable, Multitapper 1212 Automatic Threading Machine

CoastOne - Made in Finland

Demonstration Machine

Machining area: 1250 x 1250 mm

Thread sizes: M2-M10

Number of spindles: 3 (optionally 4)

2 thread cutting and forming stations; 1 countersinking and drilling station

Dcedexx R H Aspfx Afpoc

Micro-lubrication for each spindle/tool station

Control: TC15 touchscreen

Numeric input, import of punch and NC files

Warranty: 36 months after installation

Immediately available; subject to prior sale

Viewing under power is possible at any time by appointment

Listing

Austria

Austria

6,310 km

Hydr. pressbrake

HESSE by DURMAAD-S 30220

Call

Condition: new, neu

ca. 10 Wochen ab Auftrags

Türkei

88113 €

1665.34 €

220 to

3050 mm

Y1 / Y2 / X Achse

265 mm

2600 mm

450 mm

530 mm

hydraulisch

140 mm/s

10 mm/s

140 mm/s

500 mm/s

350 mm/s

Dcodpfswiqudex Afpec

250 mm

900 mm

104 mm

250 l

22 kW

4250 mm

1770 mm

3000 mm

12600 kg

Standard accessories:

3 axes (Y1, Y2,X)

CNC control DT-10

- intuitive touch-screen control (simple drawing of the bending outline with your finger)

- user friendly programming in dialogue form

- automatic calculation of bending sequence

- automatic calculation of the blank sheet size

- graphic product and tool memory

- correction possibility

- USB interfaces for backup and programm transportation

- PC software, generating programms on the PC and transfer to the machine by USB

servo motorized back gauge on linear guides and ball screws

back gauge finger blocks on double linear guides

CNC crowning table

upper tool 1010 / A / 75 °, devidedand cranked

4-V die block 60x60 2009 (V = 16,22,35 and 50 mm)

laser safety device Fiessler AKASmounted on the upper beam

linear guided sheet support arms

according to CE rules

oilfilling

users manual in English or German

ADVANTAGES OF AD-S COMPAIRED TO PDF:

- more stroke, installation height and throat

- higher approach and retraction speed of the top beam

- higher backgauge speed

- backgauge finger on double instead of single linear guide

- more options available such as: additional backgauge axes (e.g. Z1/Z2, Delta X, up to 6 axes), bending aids, laser angle measuring system, tandem design, other CNC controls ...

OPTIONAL EQUIPMENT:

R-Axis

R/Z1/Z2-Axis

DBend, 3D CAD/CAM importing- and simulation program (step, iges and dxf file import)

CNC Control Delem DA66 S

CNC Control DELEM DA-69S 3D incl. PC software Profile-S with 3D file import option

Hydraulic or pneumatic tool clamping for Euro or Wila tools

Listing

Waiblingen

Waiblingen

6,830 km

Lead/traction spindle lathe

WEILERCONDOR VC plus

Call

Condition: new, Year of construction: 2025, CONDOR VC plus

The new dimension in conventional precision lathes.

A high-quality, powerful and energy-efficient precision lathe for the highly productive area of production and toolmaking, but also for training and further education

High-quality, energy-efficient, precise and universally applicable in production, training and further education. It impresses with:

future-oriented technology

maximum accuracy

durability

user-friendly ergonomics

minimum space requirement

and a wide range of accessories.

Dcsdpfoqwipnox Afpec

The consistent and innovative further development of the tried-and-tested Condor series is the economical and intelligent solution for your daily applications.

Technical data:

WORKING AREA

Center height 180 mm

Swing diameter over bed 360 mm

Swing diameter over facing slide 190 mm

Center width 800 mm

TURNING SPINDLE

Spindle head DIN 55027/DIN ISO 702-3 size 6

Spindle bore 57 mm

Spindle diameter in front bearing 90 mm

MAIN DRIVE

Drive power 60 %/100 % ED - / 10.5 kW

Speed range 25 - 4,000 min-1

Number of speeds infinitely variable

FEED RANGE

Number stepless

Longitudinal 0.01 - 6 mm/rev

Plan 0.003 - 2 mm/rev

THREAD CUTTING RANGE

Metric thread 0.1 - 20 mm

REITSTOCK

Quill diameter 50 mm

Quill stroke 110 mm

Internal taper DIN 228 MK 3

ACCEPTANCE ACCURACY DIN 8605

Equipped with WEILER WTS 15 VC plus screen display

- Large, clearly arranged 15" touch screen,

rotatable and tiltable, resolution 1366 x 768

- Change of operating screens via swipe movements

- Operating functions can be called up via app manager

- Control panels can be freely configured,

placed and scaled as required

- Drawings / sketches can be imported from PDF files

Can be zoomed individually via USB interface

- Video-supported maintenance of the machine

- Context help menu

(instead of screen display WEILER VC plus)

The machine is located in our showroom in 71334 Waiblingen-Beinstein and is available immediately. Please contact us regarding equipment.

Listing

Waiblingen

Waiblingen

6,830 km

Band saw

Erhard+SpiessHK 3C

Call

Condition: used, Used ERHARD+SPIESS vertical band saw model HK 3C

with combined filing device.

Dodpfxjwkuyto Afpecc

Throat: 300mm

with Ideal band welding device.

Saw blade/band length approx. 2,800mm, width 3-10mm

Throughput 200mm

Cutting speed 9-800m/min, adjustable in steps

Drive 1,400 / 2,800 rpm

Table angle adjustment: right/left 15° each, forward/backward 10° each

Filing machine stroke approx. 0-120mm, workpiece thickness max. 80mm, strokes/minute 75-300

Including 5 file holders with 5 different file shapes

Delivery time: from stock. The machine can be inspected by appointment in 713334 Waiblingen Beinstein.

Listing

Bydgoszcz

Bydgoszcz

6,279 km

Universal lathe machine

PorebaTPK 90A1/10M - 10.000 mm

Call

Year of construction: 2024, condition: reconditioned (used), functionality: fully functional, This universal lathe machine can be generally overhauled and modernized and will be available within 3 to 3,5 months, starting from the customer´s order.

We give a full 12 months warranty for this machine (spare parts, material, electronic cabinet).

Details of the overhaul and detailed specs see attached PDF-files.

Dodpjkh D Txjfx Afpocc

Listing

Falkenberg

Falkenberg

6,689 km

ZEROLABOR ROBOT SYSTEM / Wall Production

RANDEK AB, SchwedenZEROLABOR

Call

Condition: new, Year of construction: 2023, ZEROLABOR ROBOTIC SYSTEM for Timber Frame Work

The Randek ZEROLABOR Robotic System is a fully automated robot cell that performs various working processes fully automatic. The system is flexible and can be configured to customers need. The robotic cell can be integrated into existing production lines or work as a stand alone unit. The system can handle production of walls, floors and roofs.

Automated processes:

- Sheet handling, the sheet is picked using vacuum cup system from various stacks and placed on building components according to CAD-file. The system is flexible and can handle various sizes of sheets.

- Fastening of sheets by screwing, stapling and/or nailing.

- Cut out for openings such as electrical hoses, windows etc.

Dedpeduub Uefx Afpecc

- The system can handle 1, 2 or 3 layers of sheets.

- Marking of component using inkjet.

- Gluing

- Waste handling, gypsum waste and OSB waste i.e. ist placed in different places if needed, i.e. directlc in waste bin/recycle bin.

- Effective dust extraction system.

- Straightening of building component using working table

- Straightening of studs before nailing, ensuring placement of nails on stud.

Listing

Berlin

Berlin

6,570 km

Sorting plant

WESTERIAWindsichter WSB 1. 1

Call

Year of construction: 2022, operating hours: 200 h, condition: like new (used), functionality: fully functional, The AirBasic is a portable machine for separating light and heavy components of various bulk materials. The machine is in as-new condition and has seen very little use. Operating instructions and data sheets are available as PDF files.

Djdpfxjyddazs Afpocc

Listing

Plauen

Plauen

6,637 km

Laser cutting machine

PFEIFER technologyskyCUBE CO2 Laser / Faser Laser

Call

Condition: new, Year of construction: 2026, The laser processing center skyCUBE M / P / SL - the new standard in laser material processing!

(* Prices depending on equipment, this is a brand new laser machine from our production)

Laser options according to your needs: CO2 laser 150W / 250W / 400W or fiber laser 1500 - 6000W

PFEIFER laser processing center skyCUBE

Processing areas:

Mclass = X 1250 x Y 650 x Z 100mm

Pclass = X 1250 x Y 1250 x Z 100 mm

SLclass = X 1250 x Y 2550 x Z 100 mm

skyCUBE laser processing center - the new multifunction laser engraving machine and laser cutting machine - laser processing easy - high precision - laser engraving, cutting with high speed and quality.

Our new and best multifunctional talent not only impresses the most experienced user with its newly thought-out construction. This CO2 laser / fiber laser shows its outstanding capabilities as a CO2 or fiber engraving laser as well as a CO2 or fiber cutting laser in all industrial applications. With an optional laser power of up to 1500W (1.5kW), the CO2 laser device / fiber laser system can also be used extremely flexibly in your production.

skyCUBE laser devices meet all requirements of class 1 according to DIN EN 60825-1 and thus offer you the highest level of safety.

Depending on the selected and installed laser power, this CO2 laser / fiber laser is ideally suited for cutting and engraving many materials, such as: various metals, acrylic glass, solid wood and wood-based materials, wood composite materials, paper, cardboard, various plastic and foam materials, textiles, and much more

The excellent design of the laser machine, 100% produced in Plauen/Germany, guarantees the laser user a high working accuracy with consistently high quality from the metal construction to the laser source. With a cutting speed of up to 8000 mm/s and an engraving speed of up to 4000 mm/s, the high-quality laser technology produces clean and very sharp cut edges and precise laser engravings.

The ergonomic design with a pull-out work table makes it easier to load the system. A drawer in the lower part of the machine is used to collect the clippings.

User-friendly and intuitive - the supplied skyCUBE PC software (ready for Windows®).

A simple, practical user interface adapted to the Windows standard lets you work quickly and effectively. The software is characterized by high system stability, professional monitoring with appropriate machine operation and control as well as compatibility with common file formats. The data is output via levels - separately for each level, including definition of the sequences and the type of processing. The parameters, such as laser power and processing speed, are automatically saved for each level and can therefore be retrieved in a material database at any time and can be reproduced. With a computer connected via LAN / USB interface, the laser projects are transferred to the skyCUBE M laser processing center. From there, these can be processed repeatedly without the PC having to be switched on.

A modern touch control panel gives you access to all system information and functions.

Laser processing center skyCUBE at a glance:

German industry standard Machine steel construction for safe and vibration-free accommodation of the laser components and axis systems, on rollable industrial leveling feet

Dcsdpjbnphvefx Afpjc

Listing

Plauen

Plauen

6,638 km

Universal machining center

Profil CNC y6000x900z270skyCNC 6008

Call

Condition: like new (used), Year of construction: 2021, operating hours: 400 h, functionality: fully functional, machine/vehicle number: skyCNC 6008, travel distance X-axis: 900 mm, travel distance Y-axis: 6,100 mm, travel distance Z-axis: 270 mm, feed rate X-axis: 20 m/min, feed rate Y-axis: 15 m/min, feed rate Z-axis: 8 m/min, workpiece length (max.): 6,000 mm, workpiece width (max.): 800 mm, workpiece diameter (max.): 270 mm, table width: 800 mm, table load: 400 kg, overall weight: 3,250 kg, spindle speed (min.): 15,000 rpm, X 900 Y 6100 Z 270 mm 11 kW (800 table) Available for immediate delivery!

PFEIFER technology skyCNC Milling Machine 6008 – 11 kW / 5 ATC (As good as new, from 2021, only 400 operating hours)

CNC Milling Machine – High-precision and powerful milling and drilling with extremely high speed and quality

A 6-meter CNC milling machine with automatic tool changer, in mint condition, is offered for sale on behalf of a customer. The machine is available for immediate delivery and ready for operation at the customer's premises; the sale is due to the conversion to laser processing. The machine can be inspected with power at the customer's/seller's premises in 07819 Triptis.

Key data:

- Working/travel area (LxWxH): 6100 mm x 900 mm x 270 mm (clearance height under gantry 300 mm, max. tool length 300 mm)

- Automatic 5-station tool changing system with ISO40 tool holder (optional 10 tool changing stations possible); includes 5x ISO40-ER32-75 tool holders and 5x ER32 collets

- HPM minimum quantity lubrication/spray cooling for cooling the workpiece and tool, automatically controlled by a solenoid valve via M-code

- T-slot table 6000 mm x 800 mm

- Includes 3 HOMGE HBV-8-300 pneumatic quick-action vises; jaw width 200 mm, clamping force up to 8.0 t – continuously adjustable; high clamping accuracy; Patented pneumatic system

- Central lubrication access points

- Automatic tool length measurement

- Mobile MPG control unit for quick and easy machine control, freely selectable workpiece zero points

- Ethernet connection for data transfer via network, USB port

Dsdpfxewlqpye Afpecc

- File formats: G-code, DIN ISO data

- Incl. industrial computer system with 17" TFT touchscreen, PC keyboard, and mouse

- HF milling spindle: HSD spindle ES951 A 1112 S / 11 kW, air-cooled; spindle speed: 3,000 - 15,000 rpm

- Power supply: 3-phase AC 400 V / 50 Hz, power consumption: max. 15 kW

- Dimensions (L x W x H): 6850 x 1440 x 2163 mm, weight: approx. 3250 kg

- Compressed air connection: min. 7 bar, including air filter required

Sale to commercial customers only!

Support and service provided by PFEIFER technology and Innovation Plauen

Listing

Plauen

Plauen

6,638 km

Milling machine skyCNC 3820

PFEIFER technology & innovationFräsmaschine skyCNC 3820 2kW

Call

Condition: new, Year of construction: 2025, travel distance X-axis: 390 mm, travel distance Y-axis: 230 mm, travel distance Z-axis: 300 mm, spindle speed (min.): 2,000 rpm, spindle speed (max.): 24,000 rpm, overall weight: 450 kg, tool diameter: 14 mm, warranty duration: 24 months, power: 2 kW (2.72 HP), If you are looking for a real machine and not a toy, then you have come to the right place: immediately ready for use, engraving, milling, drilling, for effective plastic and light metal processing.

CNC DIN ISO G code milling machine including handy CNC control

Working area: with T-slot table

X=390mm Y=230mm Z=300mm

Basic frame of the milling machine made of cast elements approx. 280kg

with base cabinet for necessary machine assemblies such as cooling and power supplies / inverter and control approx. 170kg

All axes with ball screws and 25 mm linear guides

including dust protection and manual central lubrication for all axes

Dedpfxei Hb I Tj Afpjcc

including encoder-monitored axis drive!

High-frequency spindle up to 24,000 rpm 2kW water-cooled

Collet ER20 up to max. 14 mm milling tools

- optional G code controlled minimum quantity lubrication

- optional G code controlled suction

- optional G code controlled vacuum table solution

(* Prices depending on equipment, control and spindle, this is a brand new milling machine from our production)

The milling machines are 100% manufactured according to customer requirements in our factory in Plauen!

Illustrations show different equipment variants; You will receive a brand new milling machine from our production)

Technical characteristics:

· Drive system: high-precision ball screw

· Working speed: max. 6000 mm/min

x-y-z working area / travel range: 390 mm x 230 mm x 300 mm

· Passage height: 300 mm

x-y-z increment: 0.01mm/increment

x-y-z repeatability: 0.02 mm

· File formats: G-code, ISO data

· HF milling spindle: 2.2 kW water-cooled, others optional

· Spindle speed: 6,000 - 24,000 rpm

Tool chuck ER20:

Power connection: AC 240V, 50Hz

· Power consumption: max. 2,600 W

· Dimensions (WxDxH): 1300 x 850 x 1800 mm

· Weight approx. 475 kg with base cabinet

Listing

Plauen

Plauen

6,638 km

CO2 laser engraving machine 200W

Pfeifer technologyskylaser skyCUBE M SYNRAD RF CO2 Laser

Call

Condition: new, Year of construction: 2025, The laser processing center skyCUBE M - the new standard in laser material processing!

PFEIFER laser processing center skyCube M

Laser machine with 200W CO2 laser available immediately

Mclass = machining area X 1250 x Y 650 x Z 300 mm

skyCUBE M laser processing center - the new Mclass multifunctional laser engraving machine and laser cutting machine - laser processing simple - high precision - laser engraving, cutting with high speed and quality.

Our new and best multifunctional talent not only impresses the most experienced user with its newly thought-out design. This CO2 laser / fiber laser shows its outstanding capabilities as a CO2 or fiber engraving laser as well as a CO2 or fiber cutting laser in all industrial applications. With an optional laser power of up to 1000W (1kW), the CO2 laser device / fiber laser system can also be used extremely flexibly in your production.

skyCUBE laser devices meet all the requirements of class 1 according to DIN EN 60825-1 and thus offer you the highest level of safety.

Depending on the selected and installed laser power, this CO2 laser / fiber laser is ideally suited for cutting and engraving many materials, such as: various metals, acrylic glass, solid wood, etc. Wood materials, wood composite materials, paper, cardboard, various plastics and Foams, textiles, and much more.

The excellent execution of the laser machine 100% produced in Plauen guarantees the laser user from metal construction to the laser source a high level of work accuracy with consistently high quality. With a cutting speed of up to 8000 mm / s and an engraving speed of up to 4000 mm / s, high-quality laser technology produces clean and very sharp cutting edges and precise laser engravings.

The ergonomic design with a pull-out work table makes it easier to load the system. A drawer in the lower part of the machine is used to collect the clippings.

User-friendly and intuitive - the supplied skyCUBE PC software (ready for Windows®).

A simple, practical user interface adapted to the Windows standard lets you work quickly and effectively. The software is characterized by high system stability, professional monitoring with appropriate machine operation and control as well as compatibility with common file formats. The data is output over levels - separately for each level, including the definition of the sequences and the type of processing. The parameters, such as laser power and processing speed, are automatically saved for each level and can thus be reproduced in a material database at any time. The laser projects are transferred to the skyCUBE M laser processing center with a computer connected via LAN / USB interface. From there these can be processed repeatedly without the PC having to be switched on.

A modern touch control panel gives you access to all system information and functions.

The skyCUBE M laser processing center at a glance:

Dcjdpfxe Sfanj Afpsc

German industrial standard machine steel construction for the safe and vibration-free mounting of the laser components and axis systems, on rollable industrial leveling feet

8 "touchscreen display simply see more, control more, communicate more with the skyCUBE M laser processing center

Redundant safety system - class 1 laser

Security: Shutter - ᐳ active mechanical beam path closure

Listing

Plauen

Plauen

6,638 km

PhotoGraV Photo Laser Engraving Software

ImageLazPhotoGraV Version 3.1

Call

Condition: new, Year of construction: 2025, Laser Engraving Software PhotoGraV, current software version 3.1

Dcodpfx Afscwgq Nepoc

Software for the preparation of photo data for laser engraving

With "PhotoGraV" you prepare your photos optimally for the laser output and optimize these with regard to the material to be engraved in advance, before you send the file to the laser. The software provides optimal results and this without time-consuming detours and special knowledge in image processing.

Delivery range:

PhotoGraV software, PDF manual, bonus seminar as PowerPoint presentation and more. applications

Delivered as a download (on request on DVD, plus shipping costs).

Upgrade from version 2.xx available for: 173, - Euro plus VAT

Trust Seal

Dealers certified through Machineseeker

Listing

Plauen

Plauen

6,638 km

Laser cutting machine

PFEIFER technology & innovation Plauen DskyCUBE XLs class 1550 x 3050

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, laser type: fiber laser, laser power: 6,000 W, laser wavelength: 1,064 nm, table length: 3,050 mm, table width: 1,550 mm, travel distance X-axis: 3,050 mm, travel distance Y-axis: 1,550 mm, type of input current: three-phase, overall weight: 6,500 kg, Equipment: CE marking, cooling unit, documentation/manual, safety light barrier, skyCUBE XLs class – Large Format – Shuttle Table Laser Cutting

The multifunctional flatbed laser center skyCUBE XLs class, produced by PFEIFER technology in Saxony, Germany, is engineered for your professional cutting tasks. It combines advanced productivity with economic efficiency and precision.

The machine housing is manufactured from welded and bolted steel construction, specifically designed for industrial and commercial applications. The drive system developed by PFEIFER technology ensures both precision and high repeat accuracy.

skyCUBE laser systems meet all requirements of Class 1 according to DIN EN 60825-1, providing you with maximum safety. The ergonomic design with a pull-out worktable facilitates easy loading of the machine. Drawers in the lower section collect cutting residues efficiently.

The skyCUBE laser software with file import capability generates precise laser cutting geometries for your requirements.

Optimize your cutting quality and speed—even with thick materials—thanks to the 6kW laser power, including when using compressed air. Switch between materials while maintaining consistently high cutting quality without compromise.

Monitor your production with ease: the large front doors allow convenient access to the entire working area.

Position the operator console wherever you prefer. It is mobile, providing optimal visibility of the cutting process at all times.

Naturally, your safety is the highest priority when operating the skyCUBE laser!

Dedpfx Asw Ebzmefpjcc

The skyCUBE XLs is a Class 1 laser system. There is no risk of coming into contact with laser beam emissions or reflections during operation.

With all our laser systems, nothing is more important than complete safety and compliance with the highest standards and regulations.

Special safety glass panels and a perfectly shielded cutting area reliably protect you from laser radiation risks, while an independent safety system enables loading without interrupting production.

Select the laser power that best suits your requirements; 6 kW is our current standard!

(* Pricing depends on configuration and laser power; this is a factory-new laser machine from our own production)

Maximum dimensions (L × W × H): 2310 × 8505 × 2505 mm / Laser machine: 4.0 T

Power supply: depends on laser source (6kW), 400V/50Hz, 3-phase / 27kW

Process gas control for: oxygen / nitrogen / compressed air according to material and process

Listing

Cuggiono

Cuggiono

6,871 km

Puma SMX 2100STB

DN solutions - DOOSANPuma SMX 2100STB

Call

Condition: like new (used), Year of construction: 2023, operating hours: 1,123 h, functionality: fully functional, turning length: 1,040 mm, turning diameter: 600 mm, spindle motor power: 18 W, spindle speed (min.): 20 rpm, spindle speed (max.): 4,000 rpm, spindle bore: 81 mm, travel distance X-axis: 630 mm, travel distance Y-axis: 210 mm, travel distance Z-axis: 1,085 mm, rapid traverse X-axis: 48 m/min, rapid traverse Y-axis: 36 m/min, rapid traverse Z-axis: 48 m/min, milling spindle length: 300 mm, rotational speed (max.): 12,000 rpm, rotational speed (min.): 60 rpm, spindle nose: Mandrino di fresatura Capto C6, Equipment: documentation/manual, rotational speed infinitely variable, USED 9-axis CNC multitasking Turning Center “DN Solutions model PUMA SMX2100STB” with orientable upper head equipped with tool changer, motorized lower turret, opposing spindles and Fanuc 31i-B Plus CNC, with optical scales on the X1-X2-Y-Z2 axes.

Machine options:

Top X-FILES bar loader, bar processing package, RMP 600 touch probe, bed washing pump, 360-position spindle orientation and total auto shutdown.

Dcedpfxswc R I Rs Afpjc

Fanuc options:

2 GB Data Server, 8 MB program memory and tool life management.

Listing

Lambsborn

Lambsborn

6,970 km

Machining center with throughfeed

MASTERWOODTF 100/20

Call

Condition: used, Year of construction: 2017, functionality: fully functional, TF 100/20

- Year of manufacture: 2017

- Front and rear table

- Workpiece height 60mm, maximum workpiece length unlimited

- Maximum workpiece width 1000mm, minimum width 80mm

- Traverse speed 0-25m/min

- Air tables in the work area

- 6-position tool changer

- Ball screw and linear guides

Dcedpfxsx Ha Rpo Afpec

- DXF file import

- Milling unit

- Spindle speed 1000 to 18000 rpm

- 3.3 kW

- Drilling unit with 16 drills for 5-sided machining

- Grooving saw unit

- Weight: 1380kg

- 400 Volts

- 15.8 kW

Listing

Hohenstein-Ernstthal

Hohenstein-Ernstthal

6,599 km

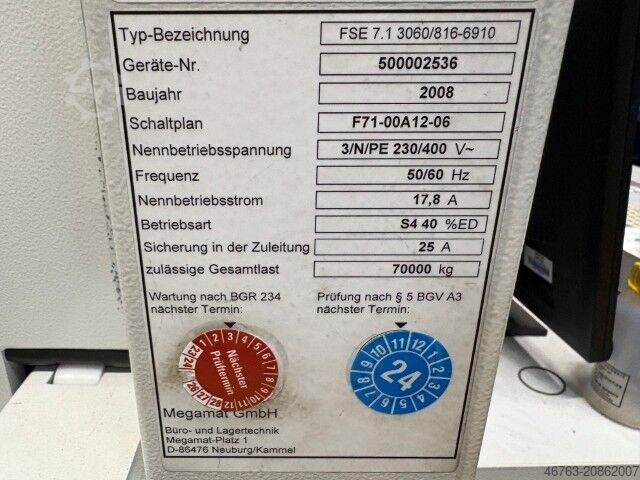

Storage lift

MegamatFSE 7.1 3060/816-6910

Call

Condition: good (used), Year of construction: 2007, Lift System, Megamat FSE 7.1, approx. 6.91m high, min. 331kg per tray, Tray size: approx. 3.06m x 81cm – used - :

Price ex location: €18,500 (net), dismantled, packed and loaded, plus transport and reassembly!

Manufacturer: Megamat

Dcsdpfxox Rzb Do Afpec

Model: FSE 7.1 3060/816-6910

Serial number: 500002536

Year of manufacture: 2008

Permissible total load: 70,000kg

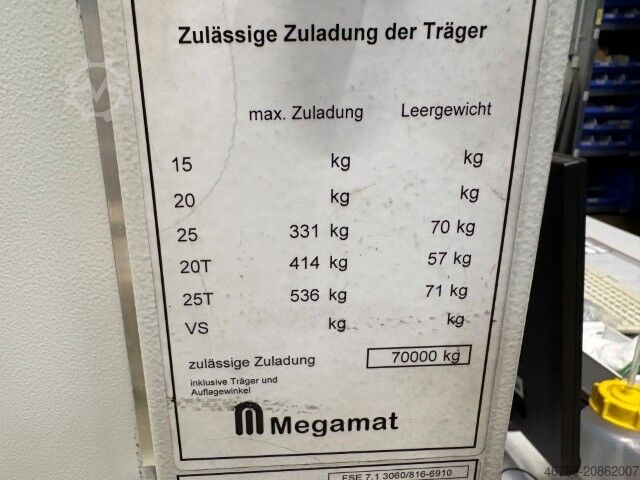

Load capacity per tray: min. 331kg (possibly 414kg or 536kg, depending on which type of tray is installed; this cannot be clarified in advance).

Number of trays: approx. 50 pieces

Tray size: 3060 x 816mm

Equipment dimensions:

Width: pending (should be approx. 3,450mm)

Depth: pending (should be approx. 3,200mm)

Height: approx. 6.91m

3/N/PE 230/400V, rated operating current 17.8A, mains fuse: 25A

Condition: good

Available: approx. end of May / beginning of June 2026

Location: 09337 Hohenstein-Ernstthal

We make it easier for you to find: "file paternoster"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used File Paternoster (648)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month