Used File Paternoster for sale (648)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Waiblingen

Waiblingen

6,830 km

Band saw

Erhard+SpiessHK 3C

Call

Condition: used, Used ERHARD+SPIESS vertical band saw model HK 3C

with combined filing device.

Throat: 300mm

with Ideal band welding device.

Ffjdpfx Aewkuytjfpsu

Saw blade/band length approx. 2,800mm, width 3-10mm

Throughput 200mm

Cutting speed 9-800m/min, adjustable in steps

Drive 1,400 / 2,800 rpm

Table angle adjustment: right/left 15° each, forward/backward 10° each

Filing machine stroke approx. 0-120mm, workpiece thickness max. 80mm, strokes/minute 75-300

Including 5 file holders with 5 different file shapes

Delivery time: from stock. The machine can be inspected by appointment in 713334 Waiblingen Beinstein.

Listing

Bydgoszcz

Bydgoszcz

6,279 km

Universal lathe machine

PorebaTPK 90A1/10M - 10.000 mm

Call

Year of construction: 2024, condition: reconditioned (used), functionality: fully functional, This universal lathe machine can be generally overhauled and modernized and will be available within 3 to 3,5 months, starting from the customer´s order.

We give a full 12 months warranty for this machine (spare parts, material, electronic cabinet).

Ffjdpfx Aokh D Txjfpju

Details of the overhaul and detailed specs see attached PDF-files.

Listing

Cuggiono

Cuggiono

6,871 km

Puma SMX 2100STB

DN solutions - DOOSANPuma SMX 2100STB

Call

Condition: like new (used), Year of construction: 2023, operating hours: 1,123 h, functionality: fully functional, turning length: 1,040 mm, turning diameter: 600 mm, spindle motor power: 18 W, spindle speed (min.): 20 rpm, spindle speed (max.): 4,000 rpm, spindle bore: 81 mm, travel distance X-axis: 630 mm, travel distance Y-axis: 210 mm, travel distance Z-axis: 1,085 mm, rapid traverse X-axis: 48 m/min, rapid traverse Y-axis: 36 m/min, rapid traverse Z-axis: 48 m/min, milling spindle length: 300 mm, rotational speed (max.): 12,000 rpm, rotational speed (min.): 60 rpm, spindle nose: Mandrino di fresatura Capto C6, Equipment: documentation/manual, rotational speed infinitely variable, USED 9-axis CNC multitasking Turning Center “DN Solutions model PUMA SMX2100STB” with orientable upper head equipped with tool changer, motorized lower turret, opposing spindles and Fanuc 31i-B Plus CNC, with optical scales on the X1-X2-Y-Z2 axes.

Ffedpfxswc R I Rs Afpeu

Machine options:

Top X-FILES bar loader, bar processing package, RMP 600 touch probe, bed washing pump, 360-position spindle orientation and total auto shutdown.

Fanuc options:

2 GB Data Server, 8 MB program memory and tool life management.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Falkenberg

Falkenberg

6,689 km

ZEROLABOR ROBOT SYSTEM / Wall Production

RANDEK AB, SchwedenZEROLABOR

Call

Condition: new, Year of construction: 2023, ZEROLABOR ROBOTIC SYSTEM for Timber Frame Work

The Randek ZEROLABOR Robotic System is a fully automated robot cell that performs various working processes fully automatic. The system is flexible and can be configured to customers need. The robotic cell can be integrated into existing production lines or work as a stand alone unit. The system can handle production of walls, floors and roofs.

Automated processes:

- Sheet handling, the sheet is picked using vacuum cup system from various stacks and placed on building components according to CAD-file. The system is flexible and can handle various sizes of sheets.

- Fastening of sheets by screwing, stapling and/or nailing.

- Cut out for openings such as electrical hoses, windows etc.

Ffodpfxjduub Ue Afpju

- The system can handle 1, 2 or 3 layers of sheets.

- Marking of component using inkjet.

- Gluing

- Waste handling, gypsum waste and OSB waste i.e. ist placed in different places if needed, i.e. directlc in waste bin/recycle bin.

- Effective dust extraction system.

- Straightening of building component using working table

- Straightening of studs before nailing, ensuring placement of nails on stud.

Listing

Hohenstein-Ernstthal

Hohenstein-Ernstthal

6,599 km

Storage lift

MegamatFSE 7.1 3060/816-6910

Call

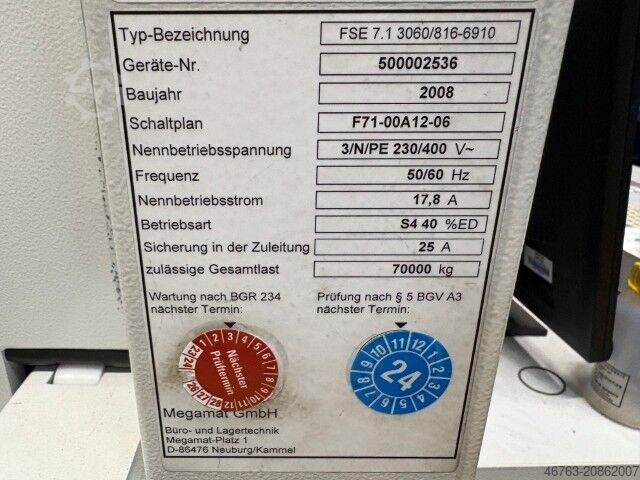

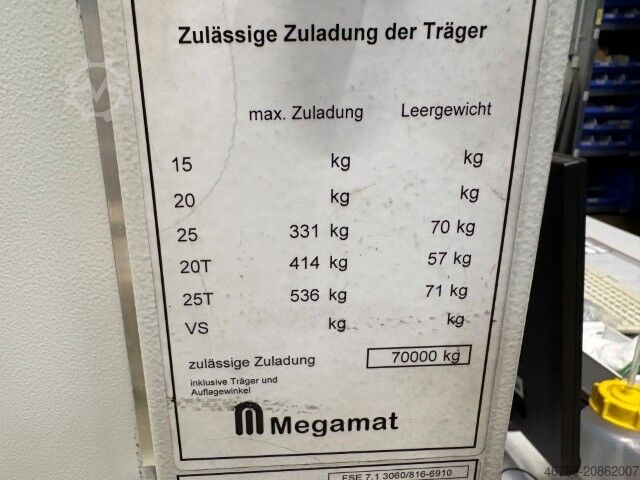

Condition: good (used), Year of construction: 2007, Lift System, Megamat FSE 7.1, approx. 6.91m high, min. 331kg per tray, Tray size: approx. 3.06m x 81cm – used - :

Price ex location: €18,500 (net), dismantled, packed and loaded, plus transport and reassembly!

Manufacturer: Megamat

Model: FSE 7.1 3060/816-6910

Serial number: 500002536

Year of manufacture: 2008

Permissible total load: 70,000kg

Fedpfox Rzb Dex Afpjfu

Load capacity per tray: min. 331kg (possibly 414kg or 536kg, depending on which type of tray is installed; this cannot be clarified in advance).

Number of trays: approx. 50 pieces

Tray size: 3060 x 816mm

Equipment dimensions:

Width: pending (should be approx. 3,450mm)

Depth: pending (should be approx. 3,200mm)

Height: approx. 6.91m

3/N/PE 230/400V, rated operating current 17.8A, mains fuse: 25A

Condition: good

Available: approx. end of May / beginning of June 2026

Location: 09337 Hohenstein-Ernstthal

Listing

Berlin

Berlin

6,570 km

Sorting plant

WESTERIAWindsichter WSB 1. 1

Call

Year of construction: 2022, operating hours: 200 h, condition: like new (used), functionality: fully functional, The AirBasic is a portable machine for separating light and heavy components of various bulk materials. The machine is in as-new condition and has seen very little use. Operating instructions and data sheets are available as PDF files.

Ffodpsyddazsfx Afpeu

Listing

Lambsborn

Lambsborn

6,970 km

Machining center with throughfeed

MASTERWOODTF 100/20

Call

Condition: used, Year of construction: 2017, functionality: fully functional, TF 100/20

- Year of manufacture: 2017

- Front and rear table

- Workpiece height 60mm, maximum workpiece length unlimited

- Maximum workpiece width 1000mm, minimum width 80mm

- Traverse speed 0-25m/min

- Air tables in the work area

- 6-position tool changer

- Ball screw and linear guides

- DXF file import

- Milling unit

- Spindle speed 1000 to 18000 rpm

- 3.3 kW

Ffodpfx Afjx Ha Rpepsu

- Drilling unit with 16 drills for 5-sided machining

- Grooving saw unit

- Weight: 1380kg

- 400 Volts

- 15.8 kW

Listing

Plauen

Plauen

6,637 km

Laser cutting machine

PFEIFER technologyskyCUBE CO2 Laser / Faser Laser

Call

Condition: new, Year of construction: 2026, The laser processing center skyCUBE M / P / SL - the new standard in laser material processing!

(* Prices depending on equipment, this is a brand new laser machine from our production)

Laser options according to your needs: CO2 laser 150W / 250W / 400W or fiber laser 1500 - 6000W

PFEIFER laser processing center skyCUBE

Processing areas:

Mclass = X 1250 x Y 650 x Z 100mm

Pclass = X 1250 x Y 1250 x Z 100 mm

SLclass = X 1250 x Y 2550 x Z 100 mm

skyCUBE laser processing center - the new multifunction laser engraving machine and laser cutting machine - laser processing easy - high precision - laser engraving, cutting with high speed and quality.

Our new and best multifunctional talent not only impresses the most experienced user with its newly thought-out construction. This CO2 laser / fiber laser shows its outstanding capabilities as a CO2 or fiber engraving laser as well as a CO2 or fiber cutting laser in all industrial applications. With an optional laser power of up to 1500W (1.5kW), the CO2 laser device / fiber laser system can also be used extremely flexibly in your production.

skyCUBE laser devices meet all requirements of class 1 according to DIN EN 60825-1 and thus offer you the highest level of safety.

Depending on the selected and installed laser power, this CO2 laser / fiber laser is ideally suited for cutting and engraving many materials, such as: various metals, acrylic glass, solid wood and wood-based materials, wood composite materials, paper, cardboard, various plastic and foam materials, textiles, and much more

The excellent design of the laser machine, 100% produced in Plauen/Germany, guarantees the laser user a high working accuracy with consistently high quality from the metal construction to the laser source. With a cutting speed of up to 8000 mm/s and an engraving speed of up to 4000 mm/s, the high-quality laser technology produces clean and very sharp cut edges and precise laser engravings.

Ffjdsbnphvjpfx Afpeu

The ergonomic design with a pull-out work table makes it easier to load the system. A drawer in the lower part of the machine is used to collect the clippings.

User-friendly and intuitive - the supplied skyCUBE PC software (ready for Windows®).

A simple, practical user interface adapted to the Windows standard lets you work quickly and effectively. The software is characterized by high system stability, professional monitoring with appropriate machine operation and control as well as compatibility with common file formats. The data is output via levels - separately for each level, including definition of the sequences and the type of processing. The parameters, such as laser power and processing speed, are automatically saved for each level and can therefore be retrieved in a material database at any time and can be reproduced. With a computer connected via LAN / USB interface, the laser projects are transferred to the skyCUBE M laser processing center. From there, these can be processed repeatedly without the PC having to be switched on.

A modern touch control panel gives you access to all system information and functions.

Laser processing center skyCUBE at a glance:

German industry standard Machine steel construction for safe and vibration-free accommodation of the laser components and axis systems, on rollable industrial leveling feet

Listing

Plauen

Plauen

6,638 km

Universal machining center

Profil CNC y6000x900z270skyCNC 6008

Call

Condition: like new (used), Year of construction: 2021, operating hours: 400 h, functionality: fully functional, machine/vehicle number: skyCNC 6008, travel distance X-axis: 900 mm, travel distance Y-axis: 6,100 mm, travel distance Z-axis: 270 mm, feed rate X-axis: 20 m/min, feed rate Y-axis: 15 m/min, feed rate Z-axis: 8 m/min, workpiece length (max.): 6,000 mm, workpiece width (max.): 800 mm, workpiece diameter (max.): 270 mm, table width: 800 mm, table load: 400 kg, overall weight: 3,250 kg, spindle speed (min.): 15,000 rpm, X 900 Y 6100 Z 270 mm 11 kW (800 table) Available for immediate delivery!

PFEIFER technology skyCNC Milling Machine 6008 – 11 kW / 5 ATC (As good as new, from 2021, only 400 operating hours)

CNC Milling Machine – High-precision and powerful milling and drilling with extremely high speed and quality

A 6-meter CNC milling machine with automatic tool changer, in mint condition, is offered for sale on behalf of a customer. The machine is available for immediate delivery and ready for operation at the customer's premises; the sale is due to the conversion to laser processing. The machine can be inspected with power at the customer's/seller's premises in 07819 Triptis.

Key data:

- Working/travel area (LxWxH): 6100 mm x 900 mm x 270 mm (clearance height under gantry 300 mm, max. tool length 300 mm)

- Automatic 5-station tool changing system with ISO40 tool holder (optional 10 tool changing stations possible); includes 5x ISO40-ER32-75 tool holders and 5x ER32 collets

- HPM minimum quantity lubrication/spray cooling for cooling the workpiece and tool, automatically controlled by a solenoid valve via M-code

- T-slot table 6000 mm x 800 mm

- Includes 3 HOMGE HBV-8-300 pneumatic quick-action vises; jaw width 200 mm, clamping force up to 8.0 t – continuously adjustable; high clamping accuracy; Patented pneumatic system

- Central lubrication access points

- Automatic tool length measurement

- Mobile MPG control unit for quick and easy machine control, freely selectable workpiece zero points

- Ethernet connection for data transfer via network, USB port

- File formats: G-code, DIN ISO data

- Incl. industrial computer system with 17" TFT touchscreen, PC keyboard, and mouse

- HF milling spindle: HSD spindle ES951 A 1112 S / 11 kW, air-cooled; spindle speed: 3,000 - 15,000 rpm

- Power supply: 3-phase AC 400 V / 50 Hz, power consumption: max. 15 kW

- Dimensions (L x W x H): 6850 x 1440 x 2163 mm, weight: approx. 3250 kg

- Compressed air connection: min. 7 bar, including air filter required

Ffodpewlqpyjfx Afpeu

Sale to commercial customers only!

Support and service provided by PFEIFER technology and Innovation Plauen

Listing

Plauen

Plauen

6,638 km

Milling machine skyCNC 3820

PFEIFER technology & innovationFräsmaschine skyCNC 3820 2kW

Call

Condition: new, Year of construction: 2025, travel distance X-axis: 390 mm, travel distance Y-axis: 230 mm, travel distance Z-axis: 300 mm, spindle speed (min.): 2,000 rpm, spindle speed (max.): 24,000 rpm, overall weight: 450 kg, tool diameter: 14 mm, warranty duration: 24 months, power: 2 kW (2.72 HP), If you are looking for a real machine and not a toy, then you have come to the right place: immediately ready for use, engraving, milling, drilling, for effective plastic and light metal processing.

CNC DIN ISO G code milling machine including handy CNC control

Working area: with T-slot table

X=390mm Y=230mm Z=300mm

Basic frame of the milling machine made of cast elements approx. 280kg

with base cabinet for necessary machine assemblies such as cooling and power supplies / inverter and control approx. 170kg

All axes with ball screws and 25 mm linear guides

including dust protection and manual central lubrication for all axes

including encoder-monitored axis drive!

High-frequency spindle up to 24,000 rpm 2kW water-cooled

Collet ER20 up to max. 14 mm milling tools

Ffjdpfx Afei Hb I Tspju

- optional G code controlled minimum quantity lubrication

- optional G code controlled suction

- optional G code controlled vacuum table solution

(* Prices depending on equipment, control and spindle, this is a brand new milling machine from our production)

The milling machines are 100% manufactured according to customer requirements in our factory in Plauen!

Illustrations show different equipment variants; You will receive a brand new milling machine from our production)

Technical characteristics:

· Drive system: high-precision ball screw

· Working speed: max. 6000 mm/min

x-y-z working area / travel range: 390 mm x 230 mm x 300 mm

· Passage height: 300 mm

x-y-z increment: 0.01mm/increment

x-y-z repeatability: 0.02 mm

· File formats: G-code, ISO data

· HF milling spindle: 2.2 kW water-cooled, others optional

· Spindle speed: 6,000 - 24,000 rpm

Tool chuck ER20:

Power connection: AC 240V, 50Hz

· Power consumption: max. 2,600 W

· Dimensions (WxDxH): 1300 x 850 x 1800 mm

· Weight approx. 475 kg with base cabinet

Listing

Plauen

Plauen

6,638 km

CO2 laser engraving machine 200W

Pfeifer technologyskylaser skyCUBE M SYNRAD RF CO2 Laser

Call

Condition: new, Year of construction: 2025, The laser processing center skyCUBE M - the new standard in laser material processing!

PFEIFER laser processing center skyCube M

Laser machine with 200W CO2 laser available immediately

Mclass = machining area X 1250 x Y 650 x Z 300 mm

skyCUBE M laser processing center - the new Mclass multifunctional laser engraving machine and laser cutting machine - laser processing simple - high precision - laser engraving, cutting with high speed and quality.

Our new and best multifunctional talent not only impresses the most experienced user with its newly thought-out design. This CO2 laser / fiber laser shows its outstanding capabilities as a CO2 or fiber engraving laser as well as a CO2 or fiber cutting laser in all industrial applications. With an optional laser power of up to 1000W (1kW), the CO2 laser device / fiber laser system can also be used extremely flexibly in your production.

skyCUBE laser devices meet all the requirements of class 1 according to DIN EN 60825-1 and thus offer you the highest level of safety.

Depending on the selected and installed laser power, this CO2 laser / fiber laser is ideally suited for cutting and engraving many materials, such as: various metals, acrylic glass, solid wood, etc. Wood materials, wood composite materials, paper, cardboard, various plastics and Foams, textiles, and much more.

The excellent execution of the laser machine 100% produced in Plauen guarantees the laser user from metal construction to the laser source a high level of work accuracy with consistently high quality. With a cutting speed of up to 8000 mm / s and an engraving speed of up to 4000 mm / s, high-quality laser technology produces clean and very sharp cutting edges and precise laser engravings.

The ergonomic design with a pull-out work table makes it easier to load the system. A drawer in the lower part of the machine is used to collect the clippings.

Fjdpfx Afo Sfanopofu

User-friendly and intuitive - the supplied skyCUBE PC software (ready for Windows®).

A simple, practical user interface adapted to the Windows standard lets you work quickly and effectively. The software is characterized by high system stability, professional monitoring with appropriate machine operation and control as well as compatibility with common file formats. The data is output over levels - separately for each level, including the definition of the sequences and the type of processing. The parameters, such as laser power and processing speed, are automatically saved for each level and can thus be reproduced in a material database at any time. The laser projects are transferred to the skyCUBE M laser processing center with a computer connected via LAN / USB interface. From there these can be processed repeatedly without the PC having to be switched on.

A modern touch control panel gives you access to all system information and functions.

The skyCUBE M laser processing center at a glance:

German industrial standard machine steel construction for the safe and vibration-free mounting of the laser components and axis systems, on rollable industrial leveling feet

8 "touchscreen display simply see more, control more, communicate more with the skyCUBE M laser processing center

Redundant safety system - class 1 laser

Security: Shutter - ᐳ active mechanical beam path closure

Listing

Plauen

Plauen

6,638 km

PhotoGraV Photo Laser Engraving Software

ImageLazPhotoGraV Version 3.1

Call

Condition: new, Year of construction: 2025, Laser Engraving Software PhotoGraV, current software version 3.1

Software for the preparation of photo data for laser engraving

With "PhotoGraV" you prepare your photos optimally for the laser output and optimize these with regard to the material to be engraved in advance, before you send the file to the laser. The software provides optimal results and this without time-consuming detours and special knowledge in image processing.

Delivery range:

PhotoGraV software, PDF manual, bonus seminar as PowerPoint presentation and more. applications

Delivered as a download (on request on DVD, plus shipping costs).

Ffedpfx Afjcwgq Nopsu

Upgrade from version 2.xx available for: 173, - Euro plus VAT

Listing

Plauen

Plauen

6,638 km

Laser cutting machine

PFEIFER technology & innovation Plauen DskyCUBE XLs class 1550 x 3050

Call

Condition: new, functionality: fully functional, Year of construction: 2025, control type: CNC control, degree of automation: automatic, laser type: fiber laser, laser power: 6,000 W, laser wavelength: 1,064 nm, table length: 3,050 mm, table width: 1,550 mm, travel distance X-axis: 3,050 mm, travel distance Y-axis: 1,550 mm, type of input current: three-phase, overall weight: 6,500 kg, Equipment: CE marking, cooling unit, documentation/manual, safety light barrier, skyCUBE XLs class – Large Format – Shuttle Table Laser Cutting

The multifunctional flatbed laser center skyCUBE XLs class, produced by PFEIFER technology in Saxony, Germany, is engineered for your professional cutting tasks. It combines advanced productivity with economic efficiency and precision.

The machine housing is manufactured from welded and bolted steel construction, specifically designed for industrial and commercial applications. The drive system developed by PFEIFER technology ensures both precision and high repeat accuracy.

skyCUBE laser systems meet all requirements of Class 1 according to DIN EN 60825-1, providing you with maximum safety. The ergonomic design with a pull-out worktable facilitates easy loading of the machine. Drawers in the lower section collect cutting residues efficiently.

The skyCUBE laser software with file import capability generates precise laser cutting geometries for your requirements.

Optimize your cutting quality and speed—even with thick materials—thanks to the 6kW laser power, including when using compressed air. Switch between materials while maintaining consistently high cutting quality without compromise.

Monitor your production with ease: the large front doors allow convenient access to the entire working area.

Ffjdpfxow Ebzms Afpsu

Position the operator console wherever you prefer. It is mobile, providing optimal visibility of the cutting process at all times.

Naturally, your safety is the highest priority when operating the skyCUBE laser!

The skyCUBE XLs is a Class 1 laser system. There is no risk of coming into contact with laser beam emissions or reflections during operation.

With all our laser systems, nothing is more important than complete safety and compliance with the highest standards and regulations.

Special safety glass panels and a perfectly shielded cutting area reliably protect you from laser radiation risks, while an independent safety system enables loading without interrupting production.

Select the laser power that best suits your requirements; 6 kW is our current standard!

(* Pricing depends on configuration and laser power; this is a factory-new laser machine from our own production)

Maximum dimensions (L × W × H): 2310 × 8505 × 2505 mm / Laser machine: 4.0 T

Power supply: depends on laser source (6kW), 400V/50Hz, 3-phase / 27kW

Process gas control for: oxygen / nitrogen / compressed air according to material and process

Listing

Soerendonk

Soerendonk

7,099 km

Double shaft shredder

RentecDinosaurus 2600S

Call

Condition: good (used), “Rentec Dinosaurus 2600S” for Sale

Ffsdpovt Tptofx Afpsu

Manufacturer: Rentec

Type: Dinosaurus 2600 S

Included Hydraulic-unit and control-unit build in container.

With overhauled rotors.

Also outlet conveyor in stock which fits to the Rentec Dinosaurs 2600S.

See PDF-file below for more detailed information.

Listing

Libina

Libina

6,279 km

Single-pass digital printer

RollencoT4

Call

Condition: excellent (used), Year of construction: 2023, functionality: fully functional, machine/vehicle number: 23100408, number of ink cartridges: 4, color channels: CMYK, number of print heads: 1, paper width (max.): 800 mm, paper height (max.): 100 mm, number of feeding trays: 1, total length: 1,800 mm, total width: 1,000 mm, total height: 1,700 mm, space requirement length: 4,000 mm, space requirement width: 2,500 mm, input current: 16 A, input voltage: 230 V, Equipment: documentation/manual, Jedo Rollenco T4 Pass-Through Digital Printer, manufactured in the EU (Netherlands), year of manufacture 2023

- Fully functional, no defects, complete with all documentation

- Only original HP inks used; prints are water-resistant and smudge-proof

- Adjustable print color density (low, medium, and high settings)

- Printer calculates printing costs (set base ink price and the printer calculates costs) — ideal for quick client quotations

- Low usage; only 232,000 labels printed

- Includes stainless steel work table on casters + adjustable stainless steel side table for finished products

- Automatic feeder suitable for small products such as paper beverage coasters, small bags, pouches, and similar items

- Complete Dell PC included, with Windows 10 and RIP Navigator software for graphic preparation

- Graphics are loaded to the printer in PDF format using the included RIP Navigator software

Fjdpsyaqrvefx Afpjfu

- Only prints on absorbent materials: paper, cardboard, wood, cotton. Does NOT print on plastics or other non-absorbent substrates

- Suitable for printing on paper pouches, paper bags, paper coasters, napkins, boxes, food packaging, catering packaging, pizza boxes, paper fan blanks (die-cuts) for paper cups, cotton bags, and similar items

- Maximum product height: 100 mm (adjustable); individual product settings can be stored in a library for quick recall

- Maximum print width: 297 mm

- Maximum product width: 800 mm

- Maximum product length: 1,500 mm

- Detailed specifications available in the attached PDF file

Standard print speed is approximately 1,000 pieces per hour. Speed is adjustable: print simple logos quickly or complex graphics at a slower pace.

I can provide basic training, a live demonstration, and further consultation if needed. The printer is very easy to set up and operate. Price includes EU-wide delivery or shipping to the Port of Hamburg.

If you have any further questions, please do not hesitate to ask.

Listing

Romania

Romania

5,627 km

Die-Sinking EDM Machine

MitsubishiEA28V ADVANCE

Call

Year of construction: 2019, operating hours: 8 h, condition: ready for operation (used), This 4-axis Mitsubishi EA28V ADVANCE die-sinking EDM machine was manufactured in 2019. It features a CNC Mitsubishi Advance M700 with a 15” touchscreen, pre-installed 3D CAD/CAM software, and supports Parasolid 3D file imports. The machine offers X/Y/Z travels of 650 × 450 × 350 mm and a C-axis with an EROWA quick-release system. Consider the opportunity to buy this Mitsubishi EA28V ADVANCE die-sinking EDM machine. Contact us for more information about this machine.

Application Types

EDM

Ffjdpsx D Enfsfx Afpsu

Listing

Silvi

Silvi

6,448 km

6-mt machining center- BIESSE Rover 24XL

BIESSERover 24 XL

Call

Condition: good (used), CNC Machining Center for Drilling and Milling Operations on Wood Panels, Derived Materials, Plastics, and Non-Ferrous Alloys

Precise and highly reliable thanks to high-quality components, this machine is ideal for both craftsmen and industrial manufacturers aiming to increase flexibility and production quality.

The main structure is made of a single welded steel base frame, constructed with thick-gauge steel plates.

TECHNICAL SPECIFICATIONS

• Working area X - Y - Z: 6,170 x 1,380 x 180 mm

• Axis stroke X - Y - Z: 6,635 - 1,780 - 250 mm

• Axis speed X - Y - Z: 100 - 100 - 30 m/min

• Worktable: 10 bars

• Bar carriages: 3

• Vacuum modules: 3 per bar

• Pendulum processing up to: 2,975 mm

• Two independent work zones allow simultaneous processing of two identical, mirrored, or different parts

• Lifting device for easy positioning of heavy and large panels

• 5-sided machining capability

• "C-shaped" open frame structure

• HSD routing unit

• Air cooling system

• Inverter included

• Tool magazine: 1 with 10 positions

• Drilling unit:

• Vertical drilling spindles: X = 7, Y = 7

• Horizontal drilling spindles: X = 2+2, Y = 1+1

• Integrated saw blade: Ø 120 mm

• Control system: NC 500 based on PC

• Easy programming and file import

• Remote control panel/console

Fsdetuxa Hjpfx Afpofu

• Teleservice and video diagnostics for real-time support

• Automatic guide lubrication system

• Vacuum pumps: 2 x 100 m³/h

• Chip conveyor belt

• Centralized extraction duct

• Extraction ports: 1 x Ø 250 mm

• Safety devices:

• Side protective curtains for the working unit

• Perimeter safety guards with access door

• Total installed power: 25 kW

• Compressed air consumption: 400 NI/min

• Operating pressure: 6.5 / 7.5 bar

• Air consumption for extraction: 3,816 m³/h

• Machine dimensions: 8,300 x 4,020 x 2,730 mm (h)

• Machine weight: 4,100 kg + 600 kg (electrical cabinet)

• Included documentation: user and maintenance manual, software manual, spare parts catalog, electrical diagram, CE declaration of conformity.

Listing

Leipzig

Leipzig

6,627 km

Machining Center - Vertical

CINCINNATI-MILACRONSabre 750

Call

Condition: used, Year of construction: 1996, Technical details:

x-travel: 762 mm

y-travel: 510 mm

z-travel: 560 mm

control: Heidenhain TNC 415 OR 360

tool changer with: 21 place

table clamping surface:: 865 x 510 mm

table load: 455 kg

tool taper: SK40

spindle revolutions per minute : 60 - 8000 U/min

feed:: X/Y/Z; 15 000 mm/min

rapid traverse : X/Y/Z: 24 m/min

compressed air: Bedarf: 5,5 bar

Total power requirement: 30 kVA

motor capacity: Spindelmotor: 11,0 kW

max. torque on the spindle: konstant: von 60 - 750 KN

Weight approx.: 4,3 t

dimension machine xH: 2,6 x 2,8 x 2,6 m

dimension coolant device: L: 2,7 x B: 0,8 x H: 0,8 m

Machining center with automatic tool changer

IKZ and coolant supply through nozzles

Chip and coolant tray

Ffjdpfx Aou Idmvofpju

Lubrication system through ball screws

Manual control unit

Heidenhain TNC 415 - dialog or according to ISO (machining cycles: deep hole drilling; tapping; slot milling; rectangular pocket and circular pocket milling; SL cycles), up to 100 programs in file management

Machine can be visited with pleasure under power.

i.D.

*

Listing

Germany

Germany

6,627 km

Band Saw - Vertical

MÖSSNER-REKORDSM 320

Call

Condition: used, Year of construction: 1983, Technical details:

throat: 315 mm

throat in width: 310 mm

throat in - height: 230 mm

saw band length: 2530 - 2650 mm

saw band width: 13 mm

band speed: 12 - 750 m/min

Table dimensions: 500 x 500 mm

table height over floor: 950 mm

total power requirement: 1,3 kW

machine weight approx.: 450 kg

dimension machine xH: 0,8 x 0,7 x 1,65 m

Fjdpeva E E Tofx Afpsfu

Steel and metal band saw

Filing band length 2550 mm

Additional equipment:

Saw band processing Ideal -> saw band cutting device-saw band welding device-saw band grinding device

Cooling via spray feeder

Foot control

Accessories

-div. saw bands

-1x running wheel Ø 320 mm

-Saw band by the meter RRR Roentgen

*

Listing

Gerolzhofen

Gerolzhofen

6,761 km

Cnc-processing center

MasterwoodPROJEKT TF 100 2.0 "PE"

Call

Condition: new, MASTERWOOD CNC machining center type PROJECT TF 100 2.0"PARTNERSHIP EDITION" - MAST0337The Masterwood CNC machining center PROJECT TFis ideal for complex CNC machining in the smallest of spaces,for solid wood, panel materials or antages:- Very little space required- Maximum time savings thanks to extremely fast production times- Fast amortization due to the low purchase price- Quick learning of the technology thanks to the simplest operation- Cleanliness of the workpieces with low suction powerby machining from below- Extremely fast, simple and variable programmingwith the MASTERWORK software (standard)- Extremely quick and easy programming completeCabinets through the use of Palette CAD (option)Technical specifications:Axes:X-axis: Max. Workpiece length: unlimitedMin. Workpiece length: 250mmTravel speed: 0-25 m / min.Y-axis: Max. Workpiece width: 1,000mm for all unitsMin. Workpiece width: 80mmTravel speed: 0-50 m / min.Z-axis: Max. Workpiece thickness: 60mmMin. Workpiece thickness: 10mmTravel speed: 0-20 m / minimum and maximum workpiece sizes aredepending on the weight and also on the ratioLength to width!Aggregates:16 mm drill head:vertical spindles in X-direction: 5 piecesvertical spindles in Y-direction: 5 pieceshorizontal double drilling spindle in X-direction:2 + 2 pieceshorizontal double drilling spindle in Y-direction:1 + 1 pieceDistance drilling spindles: 32mmSpeed ??of drilling spindles: 4,000 or: 1.7 kWGrooving saw: in the X directionSpeed: 4,000 . Saw blade diameter: 125mmMotor: 1.7 kW (the grooving saw is integrated in the drill head)Control:Personal computerProcessor: Intel Core i3-8100 CPU 3.60 GHzRAM: 8 GBHard disk: 300 GBCD-ROM driveColor screenIntegrated video card2 ethernet cardsOperating system: Windows 10 Pro - 64 bitProgram: MASTERWORK MACHINE VERSIONFurther data:Required air pressure: 8 barAir consumption: max. 750 l / tion:Volume: 2,000 m³ / hAir speed: 25 - 30 m / raction nozzle: 1 x 150mmFurther equipment features:- Air tables in the work area- Roller table in the infeed and outfeed- Sensor for plate measurement- Ball screw and linear guides- rack and pinion drive- Import of DXF files(Operating instructions, circuit and pneumatics diagram isin digital form at)"PARTNERSHIP EDITION" consisting of:Milling unit,including MASTERWORK software extensionSpeed: 1,000 to 18,000 or: 4.5 kW with ISO 30 mountIncl. integrated suction control (when drillingonly the drill head becomes, when milling only the milling unitsucked off)6-fold tool changer3 pieces ISO 30 collet chucks including colletTooling, consisting of:HW dowel drill:5 pieces 5mm - GL 70mm - blind hole drill1 piece 5mm - GL 70mm - through drill4 pieces 8mm - GL 57.5mm - blind hole drill2 pieces 10mm - GL 57.5mm - blind hole drill1 piece 10mm - GL 70mm - blind hole drill1 piece 8mm - GL 70mm - blind hole drill1 piece 15mm - GL 70mm - blind hole drill1 piece 35mm - GL 70mm - blind hole drill1 HW grooving saw blade d = 125mm, bore = 20mm, width: 4.0mm, Z = 35 WSA1 DIA milling cutter, right - GL = 103mm, NL = 43mm, D = 18mm, shank: 20x50mm, Z 1 + 11 DIA milling cutter, left - GL = 103mm, NL = 43mm, D = 18mm, shank: 20x50mm, Z 1 + 11 VHW WP finishing cutter, right, D = 10mmFoldable roller conveyor in the infeedFoldable roller conveyor in the outletAutomatic central lubricationEquipment:Complete package for CLAMEX connectors consisting of:- Angular gear with CLAMEX milling cutter including spec...

Ffodpfevwf Iisx Afpeu

Listing

Gerolzhofen

Gerolzhofen

6,761 km

Spindle moulder

SCM / Holzkraftminimax tw 45c

Call

Condition: new, - NEW -description- Stable cast steel construction- Milling spindle can be swiveled backwards from 0 ° to -45 °- Three spindle speeds from 3500 - 10000 rpm- As standard with right-left rotation of the milling spindle- Large-sized milling unit made of gray cast iron,attached directly to the table- Solid and precise gray cast iron table- Quick and easy speed change- Powerful 5.0 kW industrial motor- Standard curved milling protection hoodEquipment detailsAluminum sliding carriage- Equipped with a thousand times tried and testedBall contact system- torsion-resistant, extremely precise, smooth-running andproblem-free in daily use- 10 year Holzkraft guarantee on wear and tearof the guidewaysGray cast iron milling unit- Attached directly to the router table- Milling spindle mounted high up with precision ball bearings,thus the lowest possible bearing loadand the longest possible service life- 3 milling speeds from 3500 to 10000 rpmPowerful engines- Equipped with a powerful three-phase motorMilling protection- The milling protection is standard for maximum safetywith a height-adjustable guide railand ling stop- Exact milling stop with a quick adjustmentand a fine adjustment with a scale on the stop jaw- The integrated suction connection ensures a clear viewRouter table opening- A large router table opening also enablesthe use of larger flattening cuttersand tenoning and slotting toolsabove and below the tableArc milling protection hood- Included as standard in the scope of deliveryReversible stop jaws- Versatile integrated stop for bridgingthe tool gap- Allows you to work safely withnarrow workpiecesTechnical specifications:Dimensions and weightsWeight (net) approx. 290 kgConnection suctionExtraction nozzle diameter 2 x 120 mmWork tableWorking table length 1000 mmSlide length 1000 mmWorking table width 435 mmSlide carriage width 270 mmTable height 900 mmInstallation informationRequired space length 1945 mmMachine body width / depth 710 mmRequired space width / depth 2220 mmWorking area length 1600 mmExplanation of space requirementsThe dimensions take into account maximum travels or useful king area width / depth 1600 mmMachine body length 1000 mmExplanation of the work areaPlease add the specified dimensions with the space required in order to obtain the free installation area recommended for the ctrical dataConnection voltage 400 VMains frequency 50 HzPhase (s) 3 PhDrive motor power 5.0 kWType of current ACMilling spindleSpindle inclination 0 to -45 °Spindle speed (s) 3500/7000/10000 min¯¹Usable length of the spindle 100 mmSpindle mandrel diameter 30 mmSpindle overhang r table 130 mmMilling tool diameter l diameter can be lowered 180 mmTool diameter max. Tenon milling 275 mmTool diameter file milling 210 mmscope of deliveryArc milling protection hoodAnodized aluminum sliding carriageTelescopic miter fenceAluminum stop jawsItem No. 5502045

Ffedpfx Afovwf Ucepou

Trust Seal

Dealers certified through Machineseeker

Listing

Craiova

Craiova

5,688 km

Vertical machining center

HURCODCX32i

Call

Condition: like new (used), Year of construction: 2025, operating hours: 200 h, functionality: fully functional, machine/vehicle number: SC54G2E20145DMFCS, travel distance X-axis: 3,200 mm, travel distance Y-axis: 2,100 mm, travel distance Z-axis: 920 mm, rapid traverse X-axis: 15 m/min, rapid traverse Y-axis: 15 m/min, rapid traverse Z-axis: 10 m/min, controller manufacturer: WinMax, workpiece weight (max.): 11,000 kg, spindle speed (max.): 6,000 rpm, HURCO

3-Axis Double Column CNC Vertical Milling Center DCX 32i (SK 50)

_____

Technical specifications:

• X-axis travel – 3,200 mm

• Y-axis travel – 2,100 mm

• Z-axis travel – 920 mm

• Work surface: 3,000x1,700 mm

• Maximum table load: 11,000 kg

• Main spindle speed: 6,000 rpm

• Main spindle holder: SK 50

• Main spindle torque: 570 Nm

Base configuration:

• Main spindle cooling system;

Fjdpfxsx Shg Nj Afpofu

• Wired remote control;

• Centralized automatic lubrication system;

• ATC tool magazine with arm;

• Chip conveyor with scraper;

• Chip conveyor with rake;

• Machine interior washing system;

• Coolant/compressed air gun;

• LED-illuminated work area;

• Heat exchanger in electrical cabinet;

_____

Included options:

• Ulti-Motion - functions for reducing machining time. Cutting speed increases by 2.5 in curve/edge areas. Unlimited lookahead lines, automatic vibration reduction from cutting conditions, improved surface quality.

• Solid - Import. Option to import Step files, create contours from 3D model, automatic detection of pockets and islands, manual part origin displacement

• Simultaneous 4/5-axis machining in NC mode. Requires post-processed programs in CAM application.

• Through-spindle coolant CTS20 (20 bar)

• Workpiece measurement with probe, radio connection (Renishaw RMP 60-Q)

Installation | Training | Does not include transportation

Listing

Düsseldorf

Düsseldorf

7,014 km

5-axis CNC pivoting head saw

Cms BrembanaSPRINT 36 OF

Call

Year of construction: 2022, operating hours: 1,160 h, condition: excellent (used), functionality: fully functional, Unique custom paint finish

TECHNICAL DATA

Working Area

Worktable: 4,200 × 2,000 mm

Extension table: 4,200 × 1,000 mm

Table height: 735 mm

Load capacity of worktable: 2,000 kg

Axes

5-axis CNC swivel head saw

X-axis: 4,250 mm (0–54,000 mm/min)

Y-axis: 3,200 mm (0–54,000 mm/min)

Z-axis: 600 mm (0–12,600 mm/min)

C-axis: 540° (+/-270°), max. 9,000°/min

B-axis: +8° to -90°, max. 9,000°/min

Saw Unit

Saw motor: 18.5 kW with 120 Nm torque, 4,500 rpm

Blade diameter: min. Ø 350 mm, max. Ø 625 mm

Cutting depth: max. 200 mm (90°), max. 130 mm (45°)

Flange diameter: Ø 213.3 mm

Drive shaft: Ø 50 mm H7

Water pressure: 4 bar

Drives / Guides

Brushless servo drives

Rack and pinion and Bosch Rexroth linear/slideway guides

Fully automatic central lubrication

Traversing speed (rapid traverse) up to 54 m/min

Control

CNC control OSAl OPEN M

Integrated PC with Windows 7

Control of up to 8 axes in interpolation

Interface for *.dxf files

Remote maintenance with internet connection

Electronic pressure control and automatic tool wear compensation

CAM Software

DDX “SMART SAW” (German)

Laser

Electronic red laser for saw cut positioning

Mounted on the saw blade housing

For straight cutting operations

Electrical Cabinet / Control Panel

21.5" TFT monitor

Keyboard and joysticks

CMS Active user interface

Control panel mounted on the right side of the machine

Machine Data

Connected load: approx. 25 kW at 400 V ±5 %, 50 Hz

Noise level: approx. 75 dBA

Weight: approx. 8,000 kg

Machine dimensions: approx. 8,380 × 5,270 × 3,600 mm (W × D × H)

Safety

Complete CE safety configuration

Safety doors, covers and protective grilles

Built according to EU Machinery Directive

DESCRIPTION

5-axis CNC swivel head saw CMS Brembana Sprint 36 OF – Industrial quality for natural stone & ceramics

For sale is a 5-axis CNC swivel head saw CMS Brembana Sprint 36 OF from a professional production facility.

The machine is designed for the precise processing of natural stone, engineered stone, ceramics, porcelain stoneware, and glass.

Thanks to the powerful 18.5 kW saw unit, the full-fledged 5-axis tilting head, and CNC control OSAl OPEN M, this system is ideal for miter cuts, bevel cuts, contours, multiple cuts, and complex workpieces for high-end interior finishing.

The robust welded steel construction, premium Bosch Rexroth guides, and automatic central lubrication ensure high precision, repeatability, and long service life in continuous industrial operation.

Suitable for:

– Natural stone

– Engineered stone

– Ceramics / porcelain stoneware

– Glass

Highlights:

– 5-axis CNC swivel head saw with large working area

– Worktable 4,200 × 2,000 mm plus extension table

– CNC control OSAl OPEN M with DDX “SMART SAW”

– High positioning speeds up to 54 m/min

– Industrial-grade robust construction

– Custom paint finish according to client specification

– CE-compliant safety equipment

– Inspection by arrangement possible

Condition:

Used, very well maintained, technically flawless, in operation.

Fsdpfxjyft S Nj Afpefu

Reason for sale:

Strategic realignment of the company.

Price:

€139,000 net

Location:

North Rhine-Westphalia, Germany.

Note:

Sale as seen. Dismantling and transportation by the buyer.

Listing

Düsseldorf

Düsseldorf

7,016 km

CNC gear grinding machine reduced

ReishauerRZ 362A

Call

Condition: ready for operation (used), Year of construction: 1999, functionality: fully functional, Special price! The machine is immediately available for collection.

Grinding worm specifications:

Min/Max. outer diameter: 280/350 mm

Width: 84/104 mm

Max. module with restrictions: MOD 8.0 (DP 3.2)

Number of starts: up to 3 with limitations

Fjdpfx Afjyfnlkopofu

Max. usable width (shift travel): 90 mm

For detailed technical information, please refer to the attached PDF file.

Accessories:

Several Fässler diamond discs

Dressing device

Grinding stones

Turbo separator

Listing

Sweden

Sweden

6,422 km

Storage lift

Kardex RemstarShuttle XP250 2450x813

Call

Condition: like new (used), Year of construction: 2016, We are selling one Kardex Shuttle XP 250 (2450 × 813) from 2016. It is a smart and space-saving solution for warehouse storage.

The machine is in very good condition and features modern technology to help you organize and optimize your warehouse.

With a tray width of 2,450 mm and a machine height of 9,150 mm, it utilizes the full height of the warehouse. This saves floor space and keeps the warehouse neat and efficient.

Ffjdpoyaz R Njfx Afpeu

Items are delivered at a convenient working height, making work faster, safer, and more ergonomic.

The machine is equipped with a light pointer and confirmation buttons. The light shows the location of the item, and the buttons are used for quick and safe pick confirmation.

Integration with an ERP or WMS system is required to use the light pointer.

We make it easier for you to find: "file paternoster"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used File Paternoster (648)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month