Used Infrared for sale (246)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Rohrbach

Rohrbach

6,919 km

Fire truck

mercedes-benz319 Sprinter 6-Zylinder Rettungswagen Strobel

Call

Condition: used, mileage: 2,35,652 km, power: 140 kW (190.35 HP), first registration: 10/2016, fuel type: diesel, empty load weight: 3,100 kg, maximum load weight: 780 kg, overall weight: 3,880 kg, wheelbase: 3,665 mm, fuel: diesel, color: white, driver cabin: other, gearing type: automatic, emission class: euro6, suspension: other, number of seats: 5, total length: 6,340 mm, Year of construction: 2016, construction height: 2,820 mm, Equipment: ABS, air conditioning, airbag, central locking, electronic stability program (ESP), immobilizer system, soot filter, traction control, Standard equipment:

- Exterior mirrors electrically adjustable and heated, both sides

- Headlight range adjustment

- Exterior mirrors with integrated turn signals

- ASSYST maintenance interval display

- Washer fluid level indicator

- Driver's airbag

- Lockable glove compartment

- Roof lining in the driver's cab

Kjdpewzch Tjfx Aanjfa

- Seat upholstery: Lima fabric

- Seats in driver's cab: adjustable passenger seat

- Passenger seat with armrest

- Driver’s seat with armrest

- Electric windows (2x)

- Central locking with remote control

- Seat belt system with warning indicator (driver’s side)

- Immobilizer

- Anti-lock Braking System (ABS)

- Brake system with ABS + ASR

- Brake assist

- Steel wheels 6.5x16

- Tire repair kit with compressor

- Power steering

- Electronic Stability Program (ESP)

- Particulate filter

- Emission standard Euro 6 (low-emission)

- Fuel tank: main tank 75 L

- Wheelbase 3665 mm

- Drive type: rear-wheel drive

- Automatic transmission G-Tronic (7-speed)

- Engine 3.0 L - 140 kW CDI CAT

Special equipment:

- Steering column mechanically adjustable

- Heat-insulating glazing (windshield with top shading band)

- Programmable special module

- Exhaust ahead of rear axle, left side

- Automatic climate control (Tempmatik)

- 220 A alternator

- Fuel tank sender for auxiliary heater

- Head airbag system (windowbag)

- Comfort headrests, driver’s seat

- Comfort headrests, passenger seat

- Head-shoulder airbag (thorax airbag) for driver/passenger

- Light and rain sensor

- Passenger airbag

- Bi-xenon headlights with cornering light

- Front mud flaps

- Interior rearview mirror

- Driver assistance system: Lane Keeping Assist

- Fleece battery 95 Ah

- Reinforced front axle

- Paintable bumpers

- Comfort open/close with infrared remote control

- Rear stabilizer

- Additional main key

- Reinforced front stabilizer

- Audio system Audio 15 (radio with color display)

- Hill start assist

- Auxiliary heater (hot water)

- Folding cover for storage compartment

- Driver’s seat comfort

- Passenger seat comfort

- Outside temperature display

- 1 DIN slot front under roof lining

- Entry lights

- Roof control unit with reading lamps (driver/passenger)

- Additional battery (reinforced)

- Separation relay for additional battery

- Single-pole battery isolation switch

- Fog lights

- Mobile stretcher

- Ambulance bodywork

- Reversing camera (monitor removed)

- Rescue socket (Rettbox)

- UDS (Universal Docking Station)

- Signaling system

- Electrically operated step under sliding body door

Sale only to commercial customers (agriculture, freelancers, small and large businesses) or for export. Subject to prior sale and errors excepted.

Listing

Kraftisried

Kraftisried

6,743 km

Continuous dryer

BIRONCAR

Call

Condition: ready for operation (used), Year of construction: 2020, operating hours: 50 h, functionality: fully functional, Continuous dryer / laboratory machine

Kjdpfx Aexhxmvsanjfa

Continuous dryer with infrared heating element (LEISTER)

Suitable, for example, for furniture, moulding, or window construction

The system was purchased for measuring drying times.

Transport (crawler transport) consisting of chain drive with supporting trays

Feed via frequency inverter, 1–10 m/min.

Passage width: max. 300 mm

Listing

Blagoevgrad

Blagoevgrad

5,708 km

Edgebander

CasadeiFlexa 307

Condition: ready for operation (used), Year of construction: 2016, functionality: fully functional, machine/vehicle number: AH/119433, Touch screen control monitor

Premilling heads

Spray system in front

EVA hotmelt glue station (2pcs.)

Premelting unit

Kfjdpfx Asv R Hagoanea

Infrared ceramic lamp

Endcutting unit

Trimming unit

Corner rounding unit Round 4/A - pneumatically changed for two corners (1mm and 2mm)

Edge (corner) scraping unit SCR/S (pneumatically changed between two radius scraping - 1mm and 2mm)

Glue (flat scraping) unit

Oscilating brushing unit

Hot air for edge finish

Panel thicness 10 ÷ 60 mm

Edge thickness 0,4 ÷ 15 mm

Feed speed 10-22 m/min

It has no servo drives, but due to pneumatic changes of corner units and scraper - it can be adjusted to work with 3 edge dimensions - rough trimming for 0.4mm, and with the corner units (4pcs.) 1mm and 2mm edge.

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Germany

Germany

6,760 km

CNC Machining Center

DMGDMU 80 T

Call

Condition: ready for operation (used), A CNC 4-axis universal milling machine DMG DMU 80 T is available. Travel X/Y/Z: 880mm/630mm/630mm, spindle speed: 12000rpm, spindle power: 15kW/10kW, tool holder: SK40, tool magazine: 32, table dimensions X/Y: 1250mm/700mm, max. table load: 600kg, infrared probe: Heidenhain TS 631. Machine dimensions X/Y/Z: approx. 7600mm/3350mm/2750mm, weight: approx. 8800kg, control: Heidenhain TNC 430. Including automation extension Promot. Documentation available. An on-site inspection is possible.

Kfodpfx Aaoxg Ritonsa

Listing

Töltéstava

Töltéstava

6,200 km

O2/ CO2 incubator - calibrated!

phcbiMCO-170M-PE

Call

Year of construction: 2022, condition: refurbished (used), functionality: fully functional, !!! Calibrated, we have two units in stock. Price is for one unit only !!!

Volume: 161 l

Disinfection routine: Optional

Oxygen control: 1 - 18%, 22 - 80%

Access port diameter: 30

Data logger: Yes

Kjdpfexbiliex Aansfa

CO2 sensor type: Infrared

Chamber: Copper-enriched stainless steel

Inner glass doors: 4

Humidity alert and monitoring package: No

Minimum temperature: 26

Maximum temperature: 50

Touch screen controller: Yes

Active humidification: No

Discover more used machines

Listing

Żychlin

Żychlin

6,147 km

CO2 incubator Binder CB260 with O2

BinderCB 260 o2

Call

Condition: like new (used), Year of construction: 2024, Binder CB 260 Incubator with O2 control

The incubator is unused and originally packaged.

Model CB 260 | CO2 Incubators with Thermal Sterilization and Sterilizable CO2 Sensor

Advantages

• Safety thanks to maximum protection against contamination of cell cultures

• Reliability due to consistent comfort conditions for cells

• User-friendly thanks to easy routine cleaning and convenient operation

• Cost-effective operation without consumables

PRODUCT DESCRIPTION

The high-performance and versatile CB CO₂ incubator is suitable for cell testing in substance research and medical studies. With a wide range of options and accessories, the BINDER incubator easily fulfils complex cultivation tasks or individually specified growth conditions at low oxygen concentration.

KEY FEATURES

• Optimized dual-chamber humidification system with anti-condensation protection

• Proven anti-contamination concept with 180°C thermal sterilization

Kjdjxaungepfx Aanjfa

• Hot air sterilized CO₂ sensor with single-source infrared technology

• Seamless inner chamber made of stainless steel with stainless steel bead slide-in supports

• Fanless interior with Venturi CO₂ gas mixing nozzle

• Intuitively operated touch controller

• Internal measurement data recording system, data export via USB interface in a common format

• Fault diagnostics system with visual and audible alarm

Connections:

Ethernet, USB, volt-free alarm contact

CO₂ Fail Safe System for pH safety of cell cultures

Listing

Trittau

Trittau

6,782 km

Universal machining center

DMG MORIDMU 60 evo

Call

Condition: excellent (used), Year of construction: 2014, operating hours: 66,600 h, functionality: fully functional, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, We offer you the following:

Technical Data:

Kedpfjxgnz Tsx Aansfa

Control: Heidenhain iTNC 530 HSCI

Travel distances:

- X-axis: 600 mm

- Y-axis: 500 mm

- Z-axis: 500 mm

Main spindle:

- Speed range: 20 - 18,000 rpm

NC Rotary Table:

- Clamping surface: 600 x 500 mm

- Load capacity: 400 kg

- B-axis: -5° to +110°

- C-axis: 360°

Tool changer:

- Tool holder: HSK-A63

- Number of tool pockets: 210 positions

Equipment and Accessories:

- Heat exchanger for spindle and table

- Active cooler for control cabinet

- Direct measuring system

- Full enclosure

- 3D control

- DMG ERGOline Control

- Direct measuring systems in the NC rotary/swivel table incl. table cooling

- BLUM NT laser tool measurement

- Calibration arbor with tool holder

- Infrared probe, Heidenhain TS 649

- Preparation for 3D quickSET

- Hinged belt chip conveyor

- ICS, 40 bar, 600 l tank, incl. rotating viewing window, sealing air, linear measurement systems, bed flushing

- Rinsing pistol

- Mechanical oil and emulsion mist separator

- Air blast through spindle center

- Mode of operation 4

- Machine preparation for handling systems, consisting of:

- Automatic, lateral loading door

- Electrical interface for articulated arm robot

- Pneumatic control and monitoring of the zero-point clamping system

- Activation/deactivation of handling system via switch on machine operator panel

- Additional rinsing in the machining area included

- Preparation for job management included

- Operator panel arrangement on the left included

- Power supply to machine table incl. 2-channel rotary union

- Additional machine-side clamping hydraulics, 1 clamping circuit:

- Clamping hydraulics, 1 circuit, 30 - 240 bar, pressure adjustment via proportional valve technology

- Extension of rotary union to 4 channels included

On-time hours: approx. 66,600 h

Spindle hours: approx. 44,800 h

The robot shown in the pictures is not included in the scope of delivery.

The machine is expected to be available from October/November 2025.

The ball screw drives and linear guides in the X and Z axes have been replaced.

Accessories, depicted tools, and clamping equipment are only included if specifically mentioned in the additional information.

Subject to changes and errors in the technical specifications and information. Prior sale reserved!

Listing

Germany

Germany

8,869 km

Machining Center - Horizontal

HELLERMCT160

Call

Condition: used, Year of construction: 2003, Technical details:

x-travel: 450 mm

y-travel: 450 mm

z-travel: 450 mm

weight of the machine ca.: 14 t

size of pallet: 320 x 320 mm

number of spindles: 2

Double spindle 4-axis machining center Horizontal

4 machine plates

Renishaw probe

Control Siemens Sinumerik 840D

Working space (X / Y / Z): 450x450x450 mm

Kedpfx Aow Ng D Heansfa

Load pallet / table max .: 300 kg

Acceleration: 10 m / s²

Rapid traverse: 60 m / min

Pallet size: 320 x 320 mm

Chip-to-chip time: 2.6 s

Workpiece height max .: 700 mm

Tool holder: HSK 63

Tool places: 2x 60

Tool spindle: 10,000 rpm, 95 Nm

Speed ??increase to 18,000 rpm

Infrared receiver for probe,

Make Renishaw Vaf72a0p

Tool magazine with 60 places

Control panel on the workstation

Control panel on the tool installation site

Workpiece positioning stations can be rotated manually

with hydraulic workpiece clamping 60 bar

Pneumatic support control on the workstation

Automatic swing gate

Extended coolant layer 70 bar / 1500I /

VF 250 Coolant Cooler

Working space flushing Emulsion mist suction

Roto - Clear

Automatic setup process

Automatic disarming process

Runtime and quantity recording

Status lamp 3-color modem for remote diagnosis control cabinet lighting

*

Auction

Auction ended

Niederösterreich

Niederösterreich

6,447 km

Vertical machining center

MakinoF8

Condition: ready for operation (used), Year of construction: 2013, operating hours: 24,517 h, functionality: fully functional, travel distance X-axis: 1,300 mm, travel distance Y-axis: 800 mm, travel distance Z-axis: 650 mm, controller manufacturer: Fanuc, spindle speed (max.): 20,000 rpm, number of slots in tool magazine: 48, Bidding obligates the buyer to pick up the vehicle on time by May 30, 2025.

Disassembly and loading available for an additional charge.

Geometry report available!

TECHNICAL DETAILS

X-axis travel: 1,300 mm

Y-axis travel: 800 mm

Z-axis travel: 650 mm

Control manufacturer: Fanuc

Feed rate: 24,000 mm/min

Clamping table

Table dimensions: 1,550 x 800 mm

Spindle-to-table distance: 250 - 900 mm

Table load: max. 2.5 t

Workpiece size: 1,550 x 800 x 550 mm

Spindle

Spindle speed range: 50 - 20,000 rpm

Spindle power: 18.5 kW (S6)

Torque: 95 Nm (S6)

Tool holder: HSK63

Number of tool positions: 48

Coolant system

External coolant pressure: 7 bar

Internal coolant pressure: 40 bar

Accuracy

Positioning accuracy: ± 0.0025 mm

Repeatability: ± 0.002 mm

MACHINE DETAILS

Width: 3,850 mm

Depth: 4,090 mm

Height: 3,560 mm

Machine weight: 16,000 kg

On-time: 38,291 h

Machining time: 20,068 h

Program on-time: 24,725 h

Spindle on-time: 24,517 h

EQUIPMENT

- Electric handwheel

- Chip conveyor

Kjdpfx Aswgbx Uoansfa

- Paper belt filter

- Internal & external air supply

- Marposs infrared sensor

- Preparation for oil mist extraction

- Blum tool measurement with laser

- Work area flushing

- Manual flushing gun

- Coolant temperature control

- Machine documentation

- Geometry report

A separate tool changer can be used for dismantling and loading. Service providers can be arranged. Price: approx. €8,000

Listing

Montbrison

Montbrison

7,238 km

Universal machining center

DMG MORIDMF 300/8

Call

Condition: excellent (used), Year of construction: 2023, 5-Axis Machining Centre

Brand: DMG MORI

Model: DMF 300/8

Year: 2023 (1,600 spindle hours)

CNC: Heidenhain Celios iTNC640, 21.5'' screen

Equipped with:

• Integrated rotary table diameter 800 mm / 800 kg

• Spindle 46/30 kW – 15,000 rpm

• 90-position tool changer

• LEHMAN EA520 rotary indexer with tailstock

• BLUM LC50 laser

• PP60 Infrared probe

• Through-spindle coolant 40 bar

• Central paper filtration unit 980 litres

• Automatic doors

Ksdpfx Ajxl Ufcoanefa

• Chip conveyor

Specifications:

• Table size: 3,300 x 850 mm

• X-axis travel: 3,000 mm

• Y-axis travel: 800 mm

• Z-axis travel: 850 mm

• B-axis: -/+110°

• C-axis: 360.000°

• Spindle speed: 2 - 15,000 rpm

• Spindle power: 46/30 kW

• Spindle taper: SK 40 Big Plus

• Rapid traverse X/Y/Z: 50 m/min

• Machine dimensions approx.: 11,150 x 6,500 x H 2,650 mm

• Weight approx.: 23,500 kg

Listing

Töltéstava

Töltéstava

6,200 km

CO2 incubator - CALIBRATED !

NuaireNU-5500E

Call

Year of construction: 2011, condition: refurbished (used), functionality: fully functional, !!! Calibrated, we have two units in stock - price is for one unit only !!!

Overall Dimensions - inches (mm): Model NU-5500/E

Kfjdpfxoxbdyhe Aansa

Height: Exterior: 39.5 Inches (1003.3mm)

Width: 25.5 Inches (647.7mm)

Depth: 26.5 Inches (673.1mm)

Height: Interior: 25.5 Inches (647.7mm)

Width: 21.5 Inches (546.1mm)

Depth: 21.0 Inches (533.4mm)

Shelf Capacity: Size: 19.25 Inches (489mm) x 19.25 Inches (489mm)

Performance Parameters

- Temperature Range: 18°C to 55°C (5°C above ambient to 3°C ambient max.)

- Temperature Uniformity: +0.3°C at 37°C.

- Temperature Accuracy: +0.1°C.

- CO2 Range: 0.1 to 20%. , CO2 Accuracy: +0.1% , CO2 Recovery: Up to 5% +0.2% in 4 minutes.

- Temperature Recovery: 0.3°C/min. (Average)

- Temperature Display Resolution: 0.1°C , CO2 Display Resolution: 0.1%

- Door and Perimeter Heater Control Logic: Proportional 0-100% (adjustable) , Door & Perimeter Heater Duty cycles are processor controlled. , Temperature Sensor Type: Precision Integrated Circuit

- CO2 Control Logic: Fixed Algorithm/Manual Environmental Adaptable. , CO2 Sensor Type: Infrared , Connectors on rear panel are provided for chart recorder, remote alarm, and printer connection.

Listing

Wald

Wald

6,842 km

CO2 incubator cabinet H2O2

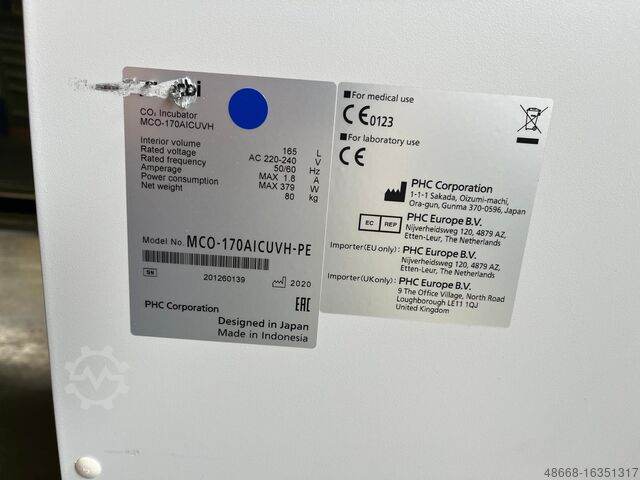

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2021, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2021

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

Kjdpfxjtxakxj Aansfa

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Freising

Freising

6,652 km

Empty bottle inspector

Krones AG

Call

Condition: used, Year of construction: 1991, Nominal capacity of filler: 60000 b/h

Power: 10,7 kW

Water: max. 4 bar, consumption: 1,3 l/min

Compressed air: 6 bar, consumption: 2,5 bar, 30 N/m³/h

Length: approx. 2.995 mm

Width: approx. 2.370 mm

Height: approx. 2.600 mm

Weight: 5200 kg

Formats: 0,33 l LongNeck-, 0,5 l NRW-bottles, bottle height: min. 150 mm/ max. 350 mm, diameter: 71 mm

Kfsdpfevcqyhjx Aanoa

Machine partitioning: 94 mm

Operation / Control: Siemens S5

Features: inspections: bottom inspection, mouth inspection, sidewall inspection, caustic detection High frequency, residual fluid detection Infrared, evaluation for detection and separation of bottles with heavy abrasion, height detection

Listing

Tallinn

Tallinn

6,065 km

Machining center

DMG MORIDMC 100 U duoBLOCK

Call

Condition: excellent (used), Year of construction: 2012, functionality: fully functional, machine/vehicle number: 11920000463, travel distance X-axis: 1,000 mm, travel distance Y-axis: 1,000 mm, travel distance Z-axis: 1,000 mm, rapid traverse X-axis: 60 m/min, rapid traverse Y-axis: 60 m/min, rapid traverse Z-axis: 60 m/min, table width: 1,000 mm, table length: 8,000 mm, spindle motor power: 35,000 W, spindle nose: HSK-63, number of slots in tool magazine: 60, Equipment: chip conveyor, documentation/manual, rotational speed infinitely variable, ACCESSORIES

Chip conveyor

Oil mist collector

Kodpfx Aer Npvljanofa

60 positions in tool changer

980 liter high pressure coolant through the spindle system with paper band filter

Infrared measuring sensor

Tool measurement with BLUM Laser

3D Quick Set preparation

Cooling unit

Air blast through the spindle

Listing

Vantaa

Vantaa

6,083 km

Breakfast cereals production line

Schaaf Technologie GmbH

Call

Year of construction: 2018, condition: excellent (used), functionality: fully functional, TYPE 318:: COATING DRUM 1600

For the application of various taste and aroma giving materials by using various aromatising techniques.

The special drum profile offers following main advantages:

- optimal rolling of the product for uniform coating

- minimum possible friction/damage of the product surface

- no hidden corners, easy to clean, bacteriologically optimal surface.

Adjustable drum speed, by frequency controlled AC gear motor 1.5 kW.

Drum diameter: 1600 mm

Drum length: 4000 mm

Drum height : 3270 mm

TYPE 284:: DRUM DRIER/ROASTER 1600 PTFE

Newly developed short and medium range infrared roaster for special thermal post treatment of expanded extrudate.

The whole drum is coated with a low-wear PTFE-layer. This secures processing of extremely sticky coated extrudates.

Unlike the conventional hot air drying process, this drying system works with a very high degree of efficiency.

The whole machine is made of rust free stainless steel. The radiation elements are attached to a common carrying arm in the drum.

The roasting drum runs on special, low-noise carrier rollers and corresponds to the safety regulations and is equipped with a corrosion free covering to reduce energy losses.

The rpm of the drum is adjustable continuously.

The drive is carried out by a three-phase motor 1.5 kW.

Drum diameter: 1600 mm

Electrical heating power: 126 kW

Drum length:4300 mm

Drum height : 2960 mm

TYPE 361:: COOLING DRUM 1600

For cooling of sticky and hot extruded products under rotation for separation.

The cooling is carried out with the help of room air, which is blown controllably into the drum by a middle pressure blower 1.85 kW AC.

Please note: depending on the product characteristics, additional cooling might be necessary for breakfastcereals before the product can be packed.

Drum diameter :1600 mm

Drum length: 4000 mm

Drum height : 2890 mm

Kedpfx Aowbqx Heanjfa

Listing

Gorzów Wielkopolski

Gorzów Wielkopolski

6,448 km

Optimisation CROSS CUT 306 4000 mm

TechnologieCNCCROSS CUT 306-4M

Call

Condition: new, Year of construction: 2024, Professional machine for removing defects from wood and wooden elements. It optimizes the cutting process and ensures minimal material losses.

The CROSS CUT 306 optimizer is a new technology of wood machines, produced by the leading brand on the Polish market, which is CNC Technologies.

The machine provides fast, simple and precise cuts to size, increasing production efficiency. The optimizer performs cross-cutting of the material into sections of a specified length, eliminating material defects marked with a fluorescent pencil and using a sensor to analyze the position of the pencil. It is worth noting that the machine can measure and cut in an automatic cycle.

Model: TechnologieCNC CROSS CUT 306-4M

Effective machining length - 4000 mm (optionally 6 m)

Effective machining width - 30-230 mm

Effective machining thickness - 40-80 mm

Effective machining in cross-section - 250x30mm

Kfedpfxotvmv Rs Aanja

Scanning speed - 80m/min

Scanning device - Infrared sensor of the German brand SICK

Scanning/detection of defects - Fluorescent sensor of the German brand SICK

Table height - 800mm

Feed speed - 60m/min

Pusher servo drive - AC DELTA 750w

Saw lift servo drive - AC DELTA 1kW

Cutting saw motor - 7.5kW, 3Ph, 2930 rpm.

Saw blade diameter - fi 500 mm

Extraction port diameter - 100mm x2

Total power: +-10kW

Overall dimensions - 6750 x 1450 x 1800mm

Transport dimensions: 535 x 80 x 110 - table, 200 x 100 x 160 - console

Weight: 1436 kg

Listing

Wiefelstede

Wiefelstede

6,930 km

UV dryer

HönleUvaprint 420 HPLK

Call

Condition: good (used), UV dryer, UV lamp, UV high-performance lamp, infrared dryer, UV dryer system, UV surface heater

-Manufacturer: Hönle, UV drying system for drying paints, varnishes and plastics

-Type: Uvaprint 420 HPLK, incl. lamp

-Number: 4x UV dryers available

-Price: per piece

Kfodpfx Aeqw D Eboansa

-Dimensions: 600/355/H140 mm

-Weight: 16 kg/piece

Listing

Wald

Wald

6,842 km

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2020, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2020

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Ksdetxaczjpfx Aanefa

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions.

- Condensation control: this prevents unwanted condensation in the chamber and possible contamination.

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Ludwigsburg

Ludwigsburg

6,842 km

Semi automatic wrapping machine

ATLANTA mit. Autom. FolienanlegenMYTHO S - NEU Arya - Mast 2400 mm - 200%

Call

Year of construction: 2025, operating hours: 1 h, condition: as good as new (ex-display), Mytho S

with TP / Transparent, accessible at ground level with lift trucks and El. lifts.

MAST VERSION

Winding height 2450 mm

99 program

TOUCH display 7"

FILM SLIDE TYPE "PRS" (POWER ROLLER STRETCH) 200% pre-stretching Optionally, more or less pre-stretching possible

Kfsdpfx Aswtc Abeanja

TURNTABLE / TP Ø1650 mm / Opening 06.00 - Mast 12.00 (can be changed at any time)

ARYA system for automatic foil blowing and cutting, incl. infrared remote control

Listing

Ulmen

Ulmen

7,002 km

Automatic Paper Collator

MKWRAPID UT32 / B3 / GS + VS3 + TD-3

Call

Condition: refurbished (used), Year of construction: 2009, functionality: fully functional, MACHINE BUILT 2009 / COMPLETELY REFURBISHED 2025

Ideal for collating calendars, folded sheets (signatures), cardboard boxes of all kinds, packaging, ...

Type - MKW RAPID

UT - System Belt conveyor table

32- Number of stations

B3 - Format 35 x 50 cm

GS - High pile up to 70 cm

1 Automatic Collator

Type MKW RAPID UT / B3 / GS

- With 32stations Belt-Conveyor-Table

Kfjdpfxoxdy R Ij Aanoa

- Sheet sizes 10 x 14 cm up to 35 x 50 cm

- High-Pile version with max. 70 cm stacking height

- Paper weights up to 1.000 g/m²

- Single sheets, folded sheets (signatures), carton, plastic foils, …

- Belt conveyor transport table for continuous sheet transport

- Timing belts radially adjustable for optimal sheet delivery

- Timing belts radial adjustment via electrical clutches

- Foldable transport fingers

- Adjustable tilt suction heads for optimal pick up of sheets

- Pressure-vacuum pump in sound-absorbing housing

- Blown air for accurate sheet layering

- Adjustable sheet layering

- Electronic machine control by Industry-PC system

- High quality color display for reliable and clear operation

- Self-learning electronic missing/double sheet control per station

- Missing/double-sheet control by Infrared sensor MKW IR

- Tandem function for double use 2 : 1 (TANDEM-Mode)

- Dynamic station selection for optimized pre-loading for the next job

- Inserting function at any station possible

- Alternating insert function at any station possible

- Alternating cardboard function at any station possible

- Speed display infinitely adjustable

- Advance counter with adjustable stop for number of sets and stop time

- Jam control along the transport table

- Active safety: Transparent safety hoods made of unbreakable PolyC.

- Ejector unit inclusive additional station at the delivery AW 3 incl.

(for ejection of faulty sets)

- Raising unit for delivery rollers AHB incl.

(for different paper formats in one set and signatures)

- Delivery Jogger-system integrated ASS i 3 incl.

(for normal and criss-cross delivery, incl. X-Jogger)

- Hand feeding station at left side HV 3

(incl. automatic station-control in case of operating error)

1 Prepiling-System for all stations

Type MKW VS 3

- Mobile stacking pallets

- Format up to 35 x 50 cm

- 30 units fixed installation in front of the machine

- 2 mobile stations in front of the collator (15+2+15)

- 2 mobile pallets per station inclusive

1 High-Pile Non-Stop Delivery Unit

Type MKW RAPID TD-3

- Automatic high-pile delivery up to 30 cm piling of sets

- Format up to 35 x 50 cm

- Staggered delivery of sets

- Stacking function adjustable: straight stacking or offset function

- Automatic delivery onto buffer belt

- Buffer belt lenght approx 2,00 m

- Counter function for pile height

- Text display for operation and monitoring

Warranty Time

12 month spare parts warranty

(critical spare parts pack shipped with machine)

(not inclusive are belts, bulbs, rubber parts, suckers, …)

Package of free spare parts

A package of the most important spare parts and consumables

like rubber parts will be send together with the machine.

Validity of offer

Subject to prior sales

Detailed offer on request

Auction

Auction ended

Hessen

Hessen

6,878 km

Horizontal machining center

HellerMCT 160

Condition: ready for operation (used), Year of construction: 2003, functionality: fully functional, travel distance X-axis: 450 mm, travel distance Y-axis: 450 mm, travel distance Z-axis: 450 mm, spindle speed (max.): 10,000 rpm, TECHNICAL DETAILS

Working Area

Working envelope (X/Y/Z): 450 × 450 × 450 mm

Maximum workpiece height: 700 mm

Pallet size: 320 × 320 mm

Maximum pallet/table load: 300 kg

Spindle

Number of spindles: 2

Tool spindle: 10,000 rpm, 95 Nm

Speed extension: 18,000 rpm

Tool interface: HSK 63

Feed

Acceleration: 10 m/s²

Rapid traverse: 60 m/min

Chip-to-chip time: 2.6 s

Tool Magazine

Tool positions: 2 × 60

Tool magazine with 60 positions: included

MACHINE DETAILS

Weight

Ksdpfx Aaswx Er Nenofa

Machine weight: approx. 14 t

Control

Control system: Siemens Sinumerik 840D

EQUIPMENT

Double-spindle, 4-axis horizontal machining center

4 machine pallets

Renishaw probe

Infrared receiver for probe, Renishaw model Vaf72a0p

Operator panel at workpiece setup station

Operator panel at tool setup station

Workpiece setup stations manually rotatable

Hydraulic workpiece clamping, 60 bar

Pneumatic support control at workpiece setup stations

Automatic swing door

Extended coolant supply 70 bar / 1,500 l

VF 250 coolant chiller

Work area flushing

Emulsion mist extraction

Roto-Clear

Automatic setup sequence

Automatic teardown sequence

Run-time and quantity recording

Status lamp, 3 colors

Modem for remote diagnostics

Control cabinet lighting

Trust Seal

Dealers certified through Machineseeker

Listing

Győr

Győr

6,204 km

Heavy duty laminator

Reliant Machinery Ltd.Powerbond-HPC 1800 Laminator System

Call

Condition: like new (used), Year of construction: 2016, operating hours: 210 h, functionality: fully functional, working width: 1,800 mm, type of cooling: water, This Reliant Powerbond HPC, 1800 mm width High Pressure Laminatint Line contain the following unites:

Kfsdsv Tmxnspfx Aansa

- Unit 1 Reliant Powerline non driven unwind unit

- Unit 1A Lightweight table designed to support sheets during feeding

- Unit 2 Reliant Powerline Powder Coating unit

- Unit 3 Reliant Powerline 3000 mm PTFE Conveyor

- Unit 4 Reliant Infrared Pre-Heating System

- Unit 4A Unwind shaft roll support for surface friction or centre unwinding

- Unit 5 Reliant Powerbond-HPC-180 Haevy Duty, High Pressure Laminating Machine

- Unit 5A Laminating Line Control Unit

- Unit 6 Reliant Powerline Centre Driven Rewind System

- Unit 7 Reliant Chiller Unit-I416

More details about the units can be found in the attached pdf file.

Loading of the machine on the transport vehicle is included in the price.

The transportation of the machine should be provided by the buyer.

Listing

Wald

Wald

6,842 km

CO2 incubator cabinet H2O2

PHCbiMCO-170AICUVH-PE

Call

Year of construction: 2020, condition: used, PHCbi MCO-170AICUVH-PE CO2 incubator cabinet H2O2 decontamination

Temperature: AT +5 ~ +50, ±0.1 °C

Kjdotxarcopfx Aanofa

Temperature uniformity: ±0.25 °C

CO2 control range and fluctuation: 0 ~ 20, ±0.15 %

Year of construction: 2020

Dimensions: 650mm x 620mm x 1000mm ( outside )

480mm x 500mm x 650mm ( inside )

Weight: approx. 80 kg

PHCbi

Creating successful cell cultures requires an incubator that offers a high level of precision and safety and is easy to use. IncuSafe offers a variety of cell culture incubators that utilize advanced technologies for unparalleled temperature and CO2 (and in some models O2) control when processing different cell cultures. These deliver long-term performance, are highly reliable and efficient.

- inCu-saFe® interior (proactive contamination control, copper-enriched stainless steel alloy): combines the germicidal properties of copper and the corrosion resistance of stainless steel.

- SafeCell UV proactive contamination control: the UV lamp isolated from the cell cultures decontaminates the circulating air and the water in the water tray without harming the cell cultures.

- H2O2 decontamination technology: PHCbi's unique high-speed decontamination system uses gaseous H2O2, enabling time-saving and documented decontamination in the chamber with a high degree of safety. Electronic door lock that automatically locks the chamber during the decontamination phase.

- Dual hot air sterilization (+ 180 °C). No interference and uninterrupted operation with stacked incubators during the sterilization cycle (model: MCO-170AICUVD-PE).

- Long-term good performance, optimal cell viability and successful experiments. It also enables precise control of CO2 concentration and temperature with easy operation and maintenance.

- Patented DHA direct heating and air jacket system*: high-precision temperature control for advanced temperature stability and fast temperature recovery times after opening the door.

- Fast CO2 recovery times: with the PID controller and the dual infrared sensor, an ultra-fast CO2 recovery time is achieved without overheating. Even after opening the door several times.

- The unique solid-state O2 zirconium oxide sensor in the multigas incubators enables precise control of physiological oxygen concentrations to simulate in vivo conditions.

Description has been adopted.

You are welcome to come by for a viewing.

We will be happy to arrange a cost-effective forwarding agent for you.

organize!

You will receive a proper invoice.

A net invoice can also be issued for foreign customers. Prerequisite is a valid VAT number.

Subject to prior sale.

Visit our store and have a look at our other offers.

Company names and trademarks are the property of their owners and are used only to identify and describe the products.

Deviations from technical data and errors in the description of the article may occur and are reserved.

Listing

Ludwigsburg

Ludwigsburg

6,842 km

Mobile pallet wrapper

ATLANTANEOS

Call

Year of construction: 2025, operating hours: 1 h, condition: as good as new (ex-display), functionality: fully functional, machine/vehicle number: S25NEOS05, Mobile stretch winder NEOS

TECHNICAL DETAILS:

HMI touch panel 7"

two maintenance-free AGM batteries 12 V - 120 Ah connected in series

Standard charger: 230 V - 1L+N+PE - 50 HZ

Autonomy 200 - 300 pallets per load

High frequency battery charger with LED indicator

Winding height machine (pallet included) 2,150 mm

Height query via light button or by entering dimensions on the display

Protective bar for emergency stop of the travel drive

Emergency stop switch according to CE regulations

Acoustic warning signal and warning light when the machine starts

Fall protection for the film slide

Push button for start & stop function of the machine according to CE standards Ø 22 mm

ADJUSTABLE WRAPPING PROGRAMS ON THE CONTROL PANEL:

F01 - 01 - cross winding (up/down)

F01 - 02 - Single wrap (up only or down only)

F01 - 03 - Complete wrap cycle with foot wraps at the same starting height

F01 - 04 - Fast cycle (with limited or no foil overlap)

F01 - 05 - layer cycle

F01 - 06 - Economical winding program

Soft start cycle for applying edge protection

Winding cycle with reinforcement and adjustable number of windings

Soft start to reduce film tears on sharp pallet edges

Winding cycle with manual or motorized line formation (optional)

ADJUSTABLE PARAMETERS ON THE CONTROL PANEL:

99 storable winding programs

All function parameters can be set via the display

F00 - Screen lock program change

Adjustable machine speed around the pallet up to 90 m/min

Lifting carriage speed can be adjusted up and down independently of each other

Lift carriage speed from 1.3 up to 5.4 m/min

Lifting carriage speed down from 1.3 to 5.4 m/min

Number of wraps on the pallet foot (1 - 10 wraps)

Number of wraps on the pallet head (1 - 10 wraps)

Adjustment pallet wrapping height

Foil application tension foot & head winding / ascent & descent independently adjustable

Foil pre-stretching foot & head wrapping / ascent & descent independently adjustable

Ergonomic height for foil change

Display foil consumption (option for PRS - PS)

FILM SLIDE TYPE “FM” WITH MECHANICAL BRAKE:

Brake can be adjusted manually from the carriage by means of a tension roller

Foil specification Max. outer diameter Ø 250 mm - core Ø76mm - height = 500 mm

Optional: stretch film with core Ø50mm or coreless stretch film

Standard connection values: 230 V - 1L+N+PE - 50 HZ

Optionally available:

-winding height up to 3500mm

-FILM CARRIAGE TYPE “FE” (ELECTROMAGNETIC BRAKE)

-FILM CARRIAGE TYPE “PRS” (POWER ROLLER STRETCH) 200%

- FILM SLIDE TYPE “PS” (POWER STRETCH) 120-400%

- PATENTED "ARYA" SYSTEM FOR PRS / PS - ARYA system for automatic foil blowing and cutting, incl. infrared remote control

-Manual cord formation on the foil carriage to strengthen the winding

-Automatic cutting unit (FE, PRS & PS)

- Machine version for temperatures down to -5° C (only version without HMI touch panel)

Other systems available immediately from the Ludwigsburg warehouse

Kfjdpsv Iqxujfx Aansa

Illustration similar.

Listing

Ludwigsburg

Ludwigsburg

6,842 km

Semi automatic wrapping machine

ATLANTA mit. Autom. FolienanlegenMYTHO S - NEU Arya - Mast 2400 mm - 200%

Call

Year of construction: 2025, operating hours: 1 h, condition: as good as new (ex-display), functionality: fully functional, Mytho S

with TP / Transparent, accessible at ground level with lift trucks and El. lifts.

MAST VERSION

Winding height 2450 mm

99 program

TOUCH display 7"

FILM SLIDE TYPE "PRS" (POWER ROLLER STRETCH) 200% pre-stretching Optionally, more or less pre-stretching possible

TURNTABLE / TP Ø1650 mm / Opening 06.00 - Mast 12.00 (can be changed at any time)

Kjdpfxjwtc Epj Aansfa

ARYA system for automatic foil blowing and cutting, incl. infrared remote control

We make it easier for you to find: "infrared"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Infrared (246)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month