Used Rebating for sale (65)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Wiefelstede

Wiefelstede

6,929 km

Milling unit

Homagmit Perske Motoren

Call

Year of construction: 1994, condition: used, Modular unit, format processing unit, cutting unit, milling unit, profile milling unit, jointing milling unit, trimming unit, double-end profiler, edge processing machine, scoring motor, chipper motor, milling motor for edge processing machine

-HOMAG milling unit can be rebated, grooved and profiled

-with keying of 2 sides each

-Milling unit: swiveling

-2x engines Perske

-Power: 0.6 kW

-Voltage: 165 volts

-Frequency: 300 Hz

-Speed: 18,000 rpm

Kdjdpob Uhp Tjfx Adweg

-Other engines with other services in stock for an additional charge

-Dimensions: 500/500/H600 mm

-Weight: 54 kg

Listing

Wiefelstede

Wiefelstede

6,929 km

Milling unit

Homagmit Perske Motoren

Call

Condition: used, Unit construction kit, format processing unit, cutting unit, milling unit, profile milling unit, jointing milling unit, trimming unit, double-end profiler, edge processing machine, scoring motor, chipper motor, milling motor for edge processing machine

-HOMAG milling unit can be rebated, grooved and profiled

-with keying: from 2 sides each

Kdsdpfx Adob Uhvfjwsg

-Milling unit: swiveling

-2x engines Perske

-Power: 0.3 kW

-Voltage: volts

-Frequency: Hz

-Speed: 18000 rpm

-Other engines with other services in stock for an additional charge

-Dimensions: 520/470/H600 mm

-Weight: 64 kg

Listing

Wiefelstede

Wiefelstede

6,930 km

Milling unit

Homag Perskemit 2x Perske Motoren

Call

Condition: good (used), Unit construction kit, format processing unit, cutting unit, milling unit, profile milling unit, jointing milling unit, trimming unit, double end profiler, edge processing machine, scoring motor, chipper motor, milling motor for edge processing machine

-HOMAG milling unit can be rebated, grooved and profiled

-with keying of 2 sides each

-Milling unit: swiveling

-Number: 2 x motors Perske

Kedpfxjvxgffj Adwedg

-Power: 0.15 kW

-Voltage: 133 volts

-Frequency: 200 Hz

-Speed: 11,160 rpm

-Other engines with other services in stock for an additional charge

-Dimensions: 470/400/H620 mm

-Weight: 55 kg

Listing

Wiefelstede

Wiefelstede

6,930 km

Milling unit

Homagmit 2x Perske Motoren

Call

Condition: good (used), Unit construction kit, format processing unit, cutting unit, milling unit, profile milling unit, jointing milling unit, trimming unit, double end profiler, edge processing machine, scoring motor, chipper motor, milling motor for edge processing machine

-HOMAG milling unit can be rebated, grooved and profiled

-with keying of 2 sides each

-Milling unit: swiveling

-Number: 2 x motors Perske

-Power: 0.15 kW

-Voltage: 133 volts

-Frequency: 200 Hz

-Speed: 11,160 rpm

-Other engines with other services in stock for an additional charge

-Dimensions: 470/400/H620 mm

-Weight: 55 kg

Kodpfx Adecv H A Newjdg

Listing

Bex

Bex

7,008 km

Woodworking machine

ESSETRE SrlTechno One 1TG–5A

Call

Condition: excellent (used), Year of construction: 2012, functionality: fully functional, machine/vehicle number: 90450080, feed length Z-axis: 1,550 mm, workpiece weight (max.): 12,500 kg, cutting height (max.): 400 mm, feed rate Y-axis: 2,700 m/min, total length: 27,500 mm, total height: 4,500 mm, cutting width (max.): 800 mm, saw blade diameter: 520 mm, overall weight: 12,500 kg, power: 40 kW (54.38 HP), working length: 12,000 mm, working width: 800 mm, type of input current: three-phase, 5-Axis CNC Timber Frame Machining Center ESSETRE Techno One 1TG–5A

5-axis timber processing center (X Y Z B C) with fixed gantry

Designed for the machining of all roof elements: straight and angled dovetail joints, tenon and mortise, hip and valley cuts, drilling with helical bits and by milling, all types of cuts, grooves and rebates – automatic feeding of beams – three tool magazines: 9, 2, and 5 positions each.

Control panel – Essetre Travi graphical software

Available tooling: saw blade, helical cutter head, tenoning cutter, roughing and straight cutters, dovetail cutters, 45° cutters, chain mortising unit

Machining dimensions: max length 12,000 mm, max section 800 × 400 mm

Overall dimensions: length 27.5 m × depth 390 cm × height 450 cm – total machine weight 12,000 kg

Kdodjxdik Rjpfx Adwog

Total installed power: 40 kW – 400 Volts – 60A – Air consumption: 400 Nl/min – Compressed air pressure: 6 bar

Complete with a set of cutters, drill bits, and various accessories

In good technical and visual condition

Ref. M26 / y12–pp410k

Listing

Schwanberg

Schwanberg

6,382 km

4 side planer

SCMprofiset 40

Call

Condition: new, Working width (finished size) 23 – 180 mm

Working height (finished size) 6 -105 mm

Min. length of single workpiece 300 mm

Feed speed 6 – 12 m/min

Motor power horizontal spindles 2 x 7.5 kW

Motor power vertical spindles 1 x 7.5 kW

Spindle speed 6000 rpm

Spindle diameter 35 mm

Clamping length vertical spindles 120 mm

Clamping length horizontal spindles 190 mm

Manual lubricant pump

Profile capacity without axial adjustment on vertical spindle 10 mm

Los roller integrated in the outfeed table

Suction DM 4 x 120 mm

Including OPTIONS:

Kdsdpfx Ajiiv Dcedwsg

- Motor-driven feed roller in front of the planer with lever for quick changeover

- Front vertical printing unit in front of the left vertical spindle

- Feed table length 2300 mm

- Tool package consisting of 4 planing heads and a joint rebate cutter

Listing

Forel (Lavaux)

Forel (Lavaux)

7,026 km

Joinery machine

HUNDEGGERK2 Industry 5 axes

Call

Condition: excellent (used), Hundegger K2 Industry 5-Axis CNC Timber Joinery Machine

5-axis machining capabilities – Maximum machining section: 300 x 620 mm

Machining operations: Section probe detector, section measurement – Cutting: All straight cuts and any angle, horizontal and vertical, birdsmouth, valley and hip rafters, rebates, half-lap joints, chamfering, groove, straight and angled birdsmouth groove, web notch – Milling with aggregate head (hogging head) and other milling cutters, mortise and tenon, mortises, notches, scarf joints, dovetail joints (straight and angled), Gerber scarf – Drilling: straight and angled, deep-hole drilling – 1x side drill and 1x underside drill.

Ink marking system – Piece identification labelling

Control console and software: The control system allows importing data from CAD software and automates the calculation of complex machining operations. Work is currently performed with CADWORK software (not included in the sale of the machine).

The machine features a pit designed for the elimination of wood waste and sawdust.

This HUNDEGGER K2 CNC is fully upgraded and refurbished!

Dimensions:

Kedpfx Adjx U Ti Uowodg

- Machine: Length 22,900 mm x Depth 5500 mm x Max. height 2550 mm (on the floor)

- Waste pit: approx. Length 12,000 x Width 2,400 x Depth 950 mm

- Timber feeding length: 13,000 mm

- Max. timber output length: 13,000 mm

- Transverse infeed conveyor: 5 chains, 2,200 mm

- Extendable timber support table

- AQF feed chain with shaft extension, 2,900 mm

- Under-table pivoting crosscut saw

- Right-hand safety flap

Waste evacuation system located below – Control for waste extraction system – Universal 5-axis milling unit with profiling tool, dovetail cutter, multiple finger joint cutter, combined vertical tool holder, drilling unit, finger joint cutter, combined horizontal tool holder, rebate unit / Drilling unit 1 and 2 – Marking device – Pneumatic beam turn-over station – Outfeed table with 7 arms

Year of manufacture: 2003

Purchased by current owner in 2020. Machine was fully reconditioned in 2020: electrical, mechanical, pneumatic, tooling, and IT systems (dismantling parts and motors, replacement of bearings, hoses, cables, guideways, IT update and EKP data export, cleaning, new tooling in 2020)

The machine is in very good technical and visual condition.

Listing

Rauhenebrach

Rauhenebrach

6,740 km

Angular window machining center

WeinigUnicontrol 10-2

Call

Condition: used, Year of construction: 1986, functionality: fully functional, spindle diameter: 50 mm, spindle stroke: 100 mm, power: 11 kW (14.96 HP), We are offering this used Weinig Unicontrol 10-2 angle machining centre, year of manufacture 1986.

Manufacturer: Michael Weinig GmbH

Model: Unicontrol 10

Year: 1986

Machine No.: 031-170

The machine is still in operation, fully functional and connected.

Earliest availability from Feb '26.

• Slotting spindle stroke: 100 mm, profiling spindle stroke: 95 mm

• Robust angle machining unit for professional wooden window processing

• Suitable for various woodworking processes: slotting, profiling, rebating

• Supplied complete with accessories and connections, but without tools

The machine runs perfectly, has been regularly maintained, and is available for inspection and demonstration by appointment.

Sale without any warranty!

Available from early Feb 2026, collection only.

Kedex Sy Ncspfx Adwedg

If you have any questions or need more information, feel free to send us a message or call us.

Listing

Oberkochen

Oberkochen

6,774 km

Four-side moulder

WEINIGPowermat 600 Compact

Call

Condition: used, Year of construction: 2014, Number of spindles 5 St.

Working width 230 mm

Working height 120 mm

Kdodjwzmu Rjpfx Adwjg

Length of the planing table 2500 mm

Feed motor 4 kW

Feed speed 5-30 m/min.

Control Memory-Funktion

Weinig Powermat 600 Compact

-----

The machine has been cleaned and fully inspected.

Brief Summary:

-----

- 5 Spindles

- Powerful Motors

- Left and top spindles controlled for width and height

Detailed Description:

-----

Technical Data:

Working Width: 20-230 mm

Working Height: 10-120 mm

Number of Spindles: 5

1st Spindle - Bottom

-----

Motor with brake: 7.5 kW

Spindle diameter: 40 mm

Speed: 6,000 rpm

Tool Circle: 125-145 mm

Tool Circle for Rebating Cutter: 130-160 mm

Axially Travel: 5 mm

Rebating Device

MarathonCoatine for table insert in front of the 1st lower tool holder

Electronic digital display for rotary adjustment

2nd Spindle - Right

-----

Motor with brake: 11.0 kW

Shared motor with left-hand tool holder

Spindle diameter: 40 mm

Speed: 6,000 rpm

Tool swing diameter 40 mm below table level: 93 - 200 mm

Tool swing diameter 55 mm below table level: 93 - 180 mm

Tool swing diameter for straight cutter heads max. 163 mm

Max. tool diameter behind fence: 180 mm

Max. groove depth: 35 mm

Axially travel: 55 mm

3rd Spindle - Left

-----

Motor with brake: Shared motor with the 2nd spindle

Spindle diameter: 40 mm

Speed: 6,000 rpm

Tool swing diameter 40 mm below table level: 93 - 200 mm

Tool swing diameter 55 mm below table level: 93 - 180 mm

Tool swing diameter for straight cutter heads max. 163 mm

Max. groove depth: 35 mm

Axially travel: 55 mm

CNC-controlled radial spindle

4th spindle - top

-----

Motor with brake: 11.0 kW

Spindle diameter: 40 mm

Speed: 6,000 rpm

Tool swing diameter: 93 - 200 mm

Tool swing diameter for straight cutter heads max.: 180 mm

Max. groove depth: 35 mm

Axially travel: 40 mm

CNC-controlled radial spindle

Split pressure shoe in front of upper tool holder, adjustable to the tool swing diameter and pivoting away from the tool, spring-loaded.

Pressure shoe in front of, and discharge after, the upper spindle with electronic

digital displays, integrated into the memory function or the PowerCom

5. Spindle - bottom

-----

Motor with brake: 7.5 kW

Spindle diameter: 40 mm

Speed: 6,000 rpm

Tool travel: 93 - 200 mm

Max. throat depth: 15 mm

Axially travel: 35 mm

Feed system

-----

Electronic feed, infinitely variable with brake: 4 kW, 5 - 30 m/min

Infeed roller in front of the first lower tool, pneumatically controlled up/down.

Durofer pointed tooth rollers with depth limiter and self-cleaning.

Adjustment travel of the feed rollers relative to the left tool holder, axial 35 mm

Machine electrical system

-----

Operating voltage 400 V (voltage range 380–420 V), 50 Hz.

All spindles IE2 design.

Electrical design according to DIN VDE 0113, electrical equipment of industrial machines EN 60204, IEC 204-1. Other electrical regulations are not considered.

Machine stand, tables, and ...

Listing

Bünde

Bünde

6,894 km

Edge banding machine

HOMAGProfi KAL310

Call

Condition: excellent (used), Year of construction: 2014, machine/vehicle number: 0-600-44-2301, HOMAG - Profi KAL310/7/A3

Comprising:

- Feeding table Profi TBL100/20/06 (HOMAG, year 2014)

- Profile KAL310/7/A3 (HOMAG, year 2014)

The KAL is suitable for processing coated wood-based materials:

- With melamine edges 0.3-0.4 mm

- With ABS and PP edges 1.0-2.0 mm (tools available: R 1.0, 1.5, 2.0)

The machine is additionally equipped with a grooving unit for vertical and horizontal grooving and rebating.

Kedpfoqi Hqijx Adwodg

If interested, the complete order confirmation can be provided.

The machine must be dismantled and loaded by the purchaser.

Listing

Trondheim

Trondheim

6,910 km

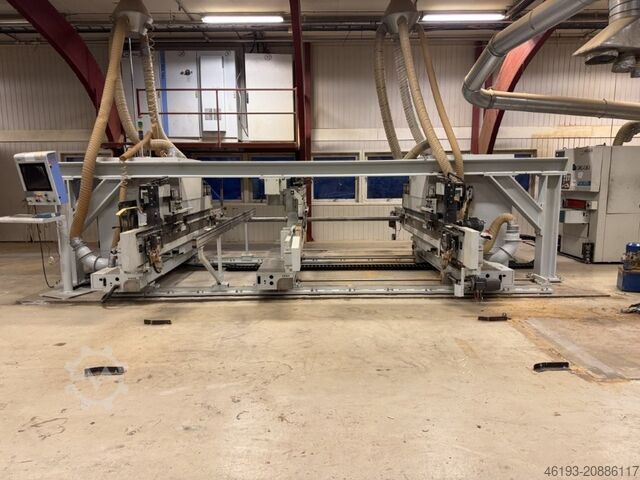

Double end tenoner

HOMAGFPL 626/03/40/W/3K

Call

Condition: ready for operation (used), Year of construction: 2009, functionality: fully functional, Equipment: documentation/manual, HOMAG FPL 626/03/40/W/3K

Double-sided HOMAG format processing machine for solid wood flooring in cross-feed through-feed operation.

Fixed reference side left, movable side right .

Technical data:

Feed speed, infinitely adjustable: 10–40 m/min

Format overhang: 3 mm (note profile depth)

Format thickness: 10–23 mm

Format length in front of lugs: max. 140–250 mm

Infeed length min: 2,400 mm

Infeed length max: 4,000 mm

Kdsdpfxjx Spxgs Adweg

Working height to top of chain: 950 mm

Pneumatic connection: 7–8 bar

Standard Milling Unit SF20, 6.6 kW – Format Section - F.01 (1323) - 1 × left, 1 × right

For grooving and rebating from the top/bottom as well as from the side, in counter-rotation.

• 1 milling motor, 6.6 kW, 100 Hz, 6,000 rpm

• Motor shaft Ø35 × 70 mm with keyway

• Swivel range: 90°, manual

• Cross-slide with electro-pneumatic control for plunge milling

• Directional switch for rotation direction

• Extraction hood

• Groove position: minimum distance 10 mm from chain track or top pressure

• Maximum tool diameter: 200 mm

• Without tools

• Electronic frequency inverter with motor braking function

• Manual horizontal and vertical adjustment via spindle and counter

Free Space for additional milling unit - 715 mm – Standard Milling Unit - F.04 (1318) - 1 × left, 1 × right

• Including extension of sound enclosure and extraction connection ports

• Without electrical pre-installation

FOR MORE TECHNICAL SPECIFICATION PLEASE READ ATTAGED DOCUMENTS in PDF format.

This machine stands in south Norway on it orginal place. The company is now closed but it is possible to inspect the machine.

Rekman Maskin & Service since 1986

Listing

Heiligenkreuz

Heiligenkreuz

6,472 km

Cut-to-size saw for wood

Panhanss45 Speed 420-320, Visioline

Call

Condition: excellent (used), Year of construction: 2011, functionality: fully functional, Cut-to-size saw with automatic swiveling saw blade

Machine type: Panhans S45 Speed 420-320, Visioline

Cutting length: 4,200 mm

Cutting width: 3,200 mm

Year of construction: 2011

Saw blade projection max. (0°): 72 mm

Saw blade diameter max .: 350 mm

Main saw motor: 14 kW

Scorer aggregate

Scorer saw blade diameter max .: 180 mm

Scorer aggregate, manually adjustable

Package height max. (0°): 60 mm

Saw aggregate forward: up to 100 m / min

Saw aggregate backward: up to 100 m / min

Feeder: up to 120 m / min (Europe: forward 25 m/min acc. EN 1870-13)

Number of clamps: 6 pcs grip push clamp

Regulation of clamp force at control desk stepless

Number of stop jaw: 2 pcs

Clamp opening: 82 mm

Strip aligner before the pressure beam

Air cushion tables: 3 pcs. 1800 x 600 mm

Angular cutting device WSA

Motor-driven cutting height adjustment for the main saw, infinately

Automatic cutting length adjustment

Grooving and rebating device

Window cutting and grooving

Formatting device

This machine is in very good conditions and works very well. The machine is reconditioned, checked and tested in our company.

Ksdpfx Ask T Aw Sedwodg

Errors and alterations in the technical datas and informations excepted!

(displayed photos are symbol photos)

Listing

Pöllau bei Hartberg

Pöllau bei Hartberg

6,338 km

Angular window machining center

SCMWINDOR 100

Call

Condition: used, Year of construction: 2005, functionality: fully functional, length stop: 3,200 mm, tool diameter: 400 mm, spindle diameter: 50 mm, spindle stroke: 640 mm, spindle speed (max.): 3,000 rpm, milling spindle length: 320 mm, saw blade diameter: 400 mm, height adjustment type: electric, type of input current: AC, working height: 130 mm, working width: 200 mm, SCM Windor 60/100 – Angle Processing Center

Manufacturer: SCM Group

Year of manufacture: 2005*

1. General Description of the System

The system in question is a window and door production line of the type Windor 60/100 from the manufacturer SCM Group, built in 2005.

It is a CNC-controlled angle processing center designed for the industrial machining of frame and sash components. The system is configured for series production and enables precise, repeatable machining in integrated process steps.

2. Main Components of the System

2.1 SCM Windor 60/100 Angle Processing Center

The SCM Windor 60/100 features a modular design and is configured as an angle processing unit. Machining takes place on a tenoning side and a profiling side positioned at right angles to each other.

The system combines several machining steps – such as milling, drilling, grooving, rebating, and tenoning – in a fully integrated, CNC-controlled process.

Key Features:

* CNC multi-sided machining

* Multiple milling and processing spindles

* Automated tool handling and changeover

* High dimensional accuracy and repeatability

2.2 Fleximat Drilling Center

The Fleximat drilling center is integrated into the system and is used for the precise execution of boreholes for joints and fittings.

Machining is CNC-controlled with both vertical and horizontal drilling units.

2.3 Profiler Center

The profiler center is designed for contour-forming milling operations and consists of two processing sides:

Right side:

* Lifting spindle with height adjustment

* Suitable for variable profile and contour processing

Left side:

* 24-position tool changer

* Automatic tool changing to minimize setup times

* Suitable for complex profile milling

2.4 Löwer Surface Sanding Machine

A surface sanding machine from Löwer is integrated into the production line.

The machine is used exclusively for surface sanding, serving to improve the surface quality of the processed workpieces.

3. Control, Operation, and Safety

The system is equipped with a CNC control unit that manages all machining operations, tool changes, as well as feed and spindle movements.

Operation is semi- or fully-automated by trained personnel.

The safety features are state-of-the-art as of the time of construction (2005) and include, in particular:

* Mechanical guards and enclosures

* Emergency stop devices

* Safety locks on moving machine parts

4. Optional Expansion: SCM Topset XL Planer (10-spindle)

For expansion of the existing machinery, provision has been made for a SCM Topset XL planer with 10 spindles.

This machine will be operated as a standalone processing station at a separate location within the production hall and is not directly integrated into the CNC control of the Windor system.

The system is available and can be dismantled at any time. Dismantling and transportation are to be organized by the buyer.

Available from 07.01.2026

Kjdpfxjx Nqqxs Adwodg

Listing

Roreto

Roreto

6,952 km

Edgebander-PRE-FORMING (DIRECT POSTFORM)

HOMAG + TREVISANVFL610/25/P/A Preforming Profiline

Call

Condition: excellent (used), SINGLE-SIDE Sizing-Milling & Edge Banding Line PRE-FORMING (DIRECT POSTFORMING), composed of the following machines:

A) Double station bridge loader "TREVISAN", with motorised roller conveyor

B) Single-side Sizing & Edge Banding "HOMAG" Mod. Profi VFL79/3/P/A Preforming

Edges (tape) thickness in rolls (min/max) max mm 0.35 (for U and L profiles)

Panel thickness (min/max) mm 16 / 30 (optional mm 50)

Working width (min/max) min mm 150 - Variable feeding speed (m/min) 10 - 32

Numerical control / PC 22 software / WoodCommander

01°) Horizontal milling unit (for top incision) Kw 2,2

02°) Hogging Unit (Kw 15) 0°-15° (for pre-hogging from above)

Kodpfx Ajnzhxqjdwedg

03°) Milling Shaping Unit Kw 6,6 (top rebate milling) with Hydro-clamp

04°) Milling Shaping Unit Kw 6,6 (bottom rebate milling) 0°-120° (with Hydro-clamp)

05°) Milling Shaping Unit Kw 0.7 (radius milling for profile finishing)

06°) Milling Shaping Unit Kw 1.85 (U profile milling) HSK25

07°) Milling Grooving unit UF 11 (Kw 4) for grooving or rebate milling

08°) Milling Shaping Unit Kw 2,2 (milling for chamfering and laminate overhang at top)

09°) Milling Shaping Unit Kw 2,2 (milling for the bottom bend groove)

10°) RIGHT SIDE: Milling Shaping Unit Kw 6,6 (grooving & rebate milling)

panel width mm 160 - 1050

11°) RIGHT SIDE: Fine trimming unit (2 x Kw 1) for top and bottom edging and finishing (0°-25°)

12°) Cleaner / Blower (Kw 0,55) of postformed piece

13°) Laminate overhang control (to detect laminate breakages)

14°) Glueing Unit (P.U.R) Glue (PU34+QA34) spray glue application (with nozzles)

15°) Pressure zone for "L" profile (VF Direct) for panels up to max. thickness 50 mm

16°) Pressure zone for "U" profile (for spacer profile R = 2.5 mm)

17°) Upper Circular Knife

18°) Fine Trimming Unit / Finishing Unit (2 x Kw 0.55) HSK25 (0°-30°)

19°) Oscillating upper cleaner (1 x Kw 0.25)

C) Double station bridge unloader "TREVISAN", with motorised roller conveyor

Listing

Germany

Germany

6,760 km

Window production centre

WEINIGUnicontrol 6 mit Werkzeuge

Call

Condition: used, Tenoning spindle 1 St.

Number of milling agregates 4 St.

Spindle diameter 50 mm

6975 Weinig Unicontrol 6, year of manufacture 1995, with electric length stop and swivel belt

.....

Sold on behalf of a customer.

The photos are from our archive and were taken before the machine was delivered to the customer.

... Technical Data Summary

(Please inquire about any additional accessories included)

.....

Crosscut Saw

.....

> Pneumatic crosscut saw, against turret stop:

> Spindle speed: 2,800 rpm

> Spindle diameter: 40 mm

> Maximum tool diameter: 350 mm

> Motor power: 3 kW

> Laser guide light for identifying the saw cut:

Length Stop

.....

> Electronic length stop

1. Tenoning and Mortising Spindle

.....

> Number of tools: 3/4 pcs.

> Tool clamping length: 320 mm

> Pneumatic vertical spindle stroke: 240 mm for wood thicknesses IV 68-92

> Spindle speed: 3,500 rpm

> Spindle diameter: 50 mm

> Maximum tool diameter: 320 mm

> Motor power: 11 kW

1. Profiling spindle - Crank-and-turn spindle (co-rotation and conventional rotation)

.....

> Position: vertical right

> Number of tools: 1

> Tool clamping length: 120 mm

> Spindle speed: 6000 rpm

> Spindle diameter: 50 mm

> Maximum tool swing diameter: 232 mm

> Motor power: 7.5 kW

2. Profiling spindle

.....

> Position: vertical right

> Number of tools: 3/4

> Tool clamping length: 320 mm

> Pneumatic vertical spindle stroke: 240 mm for wood thicknesses IV 68-92

> Spindle speed: 6000 rpm

> Spindle diameter: 50 mm

> Maximum tool swing diameter: 232 mm

> Motor power: 11 kW

3. Profiling spindle (fitting spindle)

.....

> Position: vertical right

> Number of tools: 3

> Spindle speed: 6000 rpm

> Spindle diameter: 40 mm

> Maximum tool swing diameter: 180 mm

Ksdpfx Aox Dngwjdwodg

> Motor power: 3 kW

4. Grooving unit, horizontal-vertical indexing

.....

> Position: horizontal top

> Number of tools: 1

> Tool clamping length: 40 mm

> Spindle diameter: 40 mm

> Maximum tool swing diameter: 130 mm

> Motor power: 3 kW

Further features

.....

> Rebating device for tear-out-free rebating

> Double part package

> Return feeder for one-person operation

> Screen control

> Slanted window fitting

> Electronic angle indicator for slanted windows

> Clocked muntin bar support rail

Includes

.....

Used Leitz 78/90 wood and wood/aluminum window tools, manufactured in 2013

Technical specifications according to the manufacturer - without guarantee!

Listing

Oberkochen

Oberkochen

6,774 km

4 side moulder

WEINIGUnimat 23 E

Call

Condition: used, Number of spindles 6 St.

Working width 230 mm

Working height 120 mm

Length of the planing table 2000 mm

Feed motor 4 kW

Feed speed 5-24 m/min.

1 WEINIG Unimat 23 E Planer and moulder

-----

6 spindles (with 2 rigth spindles, reinforced motors, 8,000 rpm, ATS control

Machine will be cleaned and functionally checked before delivery

Working width 20 - 230 mm

Working height 8 - 120 mm

1st spindle (bottom) 5.5 kW (motor replaced)

-----

Diameter 40 mm

Speed ??6,000 rpm

Tool swing diameter 125 - 180 mm

Rebating unit including tool

Hardened table insert in front of 1st (bottom) spindle

2nd spindle (right) 12.1 kW (motor replaced)

-----

Shared motor with left vertical spindle

Diameter 40 mm

Speed ??8,000 rpm

Tool swing diameter 112-250 mm

Max. Tool diameter behind stop plane 203 mm

Max. groove depth 35 mm

Axially travel 80 mm

3. Spindle, left

-----

Shared motor with 2nd spindle

Diameter 40 mm

Speed ??8,000 RPM

Tool swing diameter 112-200 mm

Max. groove depth 35 mm

Axially travel 80 mm

Pressure shoe in front of left spindle, including

spring-loaded lateral roller pressure

4. Spindle, right 8.3 kW (motor replaced)

-----

Diameter 40 mm

Speed ??8,000 RPM

Tool swing diameter 112-250 mm

Max. tool diameter behind stop plane 203 mm

Max. groove depth 35 mm

Axially travel 80 mm

5. Spindle, top 7.5 kW

-----

Diameter 40 mm

Speed ??8,000 rpm

Tool travel 112-200 mm

Kdsdpfexz Hh Uex Adwsg

Max. groove depth 35 mm

Axially travel 45 mm

Split pressure shoe in front of upper spindle, adjustable to the tool travel

and pivoting away from the tool, spring-loaded.

6. Lower spindle 4.0 kW

-----

Diameter 40 mm

Speed ??6,000 rpm

Tool travel 112-250 mm

Max. groove depth 15 mm

Axially travel 45 mm

Spindles in general

-----

All groove spindles with high concentricity.

Lubrication points for the axial spindle movement.

Feed system

-----

Motor with mechanical brake, 4 kW

Mechanical feed infinitely variable 5-24 m/min.

Feed roller in front of the first lower tool

pneumatically controlled up/down,

Durofer pointed tooth rollers (Weinig patent) with

depth limiter and self-cleaning

Adjustment travel of the feed rollers relative to the left

spindle, axial 35 mm

Machine electrical system

-----

Operating voltage 440 V (voltage range 380 - 420 V), 50 Hz.

Machine frame, tables and stops

-----

Infeed table 2.0 m long (incl. jointing guide)

Manual Waxilit pump for table de-resin removal

One driven rubber roller (spring-loaded in the outfeed table)

Two driven rollers in the machine table, hardened

Machine operation

-----

Pressure shoe in front of the upper spindle with mechanical digital display.

Extraction after the upper spindle with mechanical digital display.

ATS/System, automatic 2-axis positioning for spindles 3 and 5

Minimum working height 12 mm

Electric height adjustment of the upper spindles

and the feed

Central lubrication points on the front of the machine

Electronic digital displays on spindles 3 and 5 (axial), spindle 6 (radial)

and spindle 4 (axial and radial)

Safety and noise reduction

-----

Full safety enclosure

Easily hinged safety hood with window. Covers the e...

Listing

Aalen

Aalen

6,772 km

Glazing bead sww

RUCHSERRU-GLS-ED 45°

Call

Condition: new, Number of motors 2 Stück

0 2650 mm

Control manuell

Ruchser RU-GLS-ED 45° glazing bead saw

-----

Developed for cutting glazing beads in pairs

The RU-GLS-ED45° double glazing bead saw can be adjusted manually to size. The

Machine was designed for cutting glazing beads in pairs with one

Cutting angle of 45° developed and has a fixed and a

movable saw unit. The manual length adjustment is equipped with

an electric digital display. Cutting lengths of 150 mm - 2650 mm can be achieved

be sawn. During the cutting process, the glazing beads are with a

pneumatic tensioning device from above and from the front to prevent tipping

of the glazing beads. It is operated via a safety

Two-hand operation. Saw blade diameter 250 mm, length 3700 mm, width 700 mm,

Voltage 400V

Pos. 1: RU-GLS-ED45° double glazing bead saw

-----

with manual measurement adjustment, for pairs

Cutting glazing beads, cutting angle 45°.

Manual length adjustment with electric

Digital display, cutting length from 150 - 2650 mm.

Pneumatic clamping device from above and from

in front. Safety two-hand operation, saw blade diameter

250 mm, length 3700 mm, width 700 mm,

Voltage 400V

-----

Basic price in the above version: on request!

-----

Ex works. Plus packaging and shipping as well as current

Material cost surcharge of 6% of the total price

Options with additional costs:

-----

Item 1.1 Set of inserts for rebated glazing beads

for RU-GLS-P45° and RU-GLS-ED45°

Price request, after checking the glazing beads.

Depending on the number of glazing beads used, this can happen

several sets of inserts are required. To determine the exact number

In order to be able to do this, we need profile drawings before order confirmation

the glazing beads to be used.

Additional charge: on request, after sending your glazing bead drawings

Pos. 1.2 Recording device for scanning gauge

RU-GL for transferring the scanning dimensions to the saw

with pneumatic installation.

Additional price: 611.00 euros

Pos. 1.3 Measuring gauge for glazing beads, total length

2550 mm, max. scanning length approx. 2450 mm

Measuring gauge made of square profile with 2 fixed and

2 adjustable cams for measuring the length of the glazing bead

Additional price: 478.00 euros

Pos. 1.4 Measuring gauge for glazing beads, total length

1500 mm, max. scanning length approx. 1430 mm

Measuring gauge made of square profile with 2 fixed and

2 adjustable cams for measuring the length of the glazing bead

Additional price: 428.00 euros

Pos. 1.5 Operating time switching device for

independent suction.

Adjustable from 5 seconds. up to 3 hours. With every sawing process

automatically becomes the set time

sucked off. Will be used again within the suction time

sawn, the set suction time begins

again from the beginning.

Additional price: 702.00 euros

Item 1.6

1 set of carbide saw blades

RU-GLS-P45 and RU-GLS-ED45°

D = 250 mm x 3.2/2.2 x 30, 80 teeth,

each consisting of 1 piece of saw blade

L6444(right) and L6443, (left),

with special grinding 43°.

Additional price: 576.00 euros

Kjdpfx Aoxmk Dqodwodg

-----

All prices in euros, net, plus statutory. VAT

(technical information according to the manufacturer, without guarantee!)

Listing

Berlin

Berlin

6,547 km

Circulation machine

WEINIGUnivar 10

Call

Year of construction: 1987, condition: excellent (used), Automatic rebating machine

WEINIG UNIVAR 10

Kdodpfx Aof Upzhjdwsg

Listing

Germany

Germany

6,760 km

Window production centre

WEINIGUnicontrol 6

Call

Condition: used, Tenoning spindle 1 St.

Number of milling agregates 4 St.

Spindle diameter 50 mm

# 2809 Weinig Unicontrol 6

-----

Technical Specifications Summary

(Please inquire about any additional accessories included)

Item 1: Crosscut Saw

-----

> Number of tools: 1 pc.

> Spindle speed: 2,800 rpm

> Spindle diameter: 40 mm

> Maximum tool diameter: 400 mm

> Motor power: 3.0 kW

> Laser alignment light for detecting the saw cut

CNC-controlled length stop

-----

> Length 3,500 mm

> Electronic length stop including positioned crosscut saw

Item 2: Tenon and slotting spindle

-----

> Number of tools: 3 (stroke 2 x 100) mm) or 4 (stroke 3 x 80 mm)

> Tool clamping length: 320 mm

> Vertical pneumatic spindle stroke: 240 mm for wood thicknesses 68 - 92 mm

> Spindle speed: 3000 rpm

> Max. tool travel circle: 320 mm

> Spindle diameter: 50 mm

> Max. tool diameter: 360 mm

> Motor power: 11 kW

Item 3: 1st profiling spindle (straight and counter-rotating)

-----

> Position: vertical right

> Number of tools: 1

> Tool clamping length: 120 mm

> Spindle speed: 6000 rpm

> Spindle diameter: 50 mm

> Max. tool travel circle: 232 mm

> Motor power: 7.5 kW

Item 4: 2nd profiling spindle

-----

> Position: vertical right

> Number of tools: 3 (stroke 2 x 100 mm) or 4 (stroke 3 x 80 mm)

> Tool clamping length: 320 mm

> Vertical pneumatic spindle stroke: 240 mm for wood thicknesses 68 - 92 mm

> Spindle speed: 6000 rpm

> Spindle diameter: 50 mm

> Maximum tool travel: 232 mm

> Motor power: 11 kW

2 axially indexed feed rollers opposite the profiling spindle,

for the production of narrow, short parts (e.g., glass-parted muntins)

Muntin guide consisting of:

Muntin support bar from above in the area of ??the profile milling unit vertically on the right

and the profiling spindle.

Item 5: Profile milling unit, horizontal, top

-----

> Clamping length: 40 mm

> Spindle diameter: 40 mm

> Motor power: 3.0 kW

> Speed: 5,850 rpm

> Tool travel radius max. 130 mm

> Axial adjustment range: 30 mm, 2 positions

> Radial adjustment range: 125 mm, 4 positions, manual

Item 6: 3rd profiling spindle (fitting spindle)

-----

> Position: vertical right

> Tool clamping length: 160 mm

> Axial adjustment range: 115 mm, 8 positions via pneumatic turret

Kdsdpfextvgkox Adwsg

> Radial adjustment range: 110 mm, 8 positions via pneumatic turret

> Spindle speed: 5,850 rpm

> Spindle diameter: 40 mm

> Tool travel radius Max.: 210 mm

> Motor power: 3.0 kW

Other features

-----

> Electric feed height adjustment including mechanical digital display

and manual feed bar clamp

> Rebating device for tear-free rebating

> Double parts package

> Return conveyor for one-person operation: swivel belt

> Screen control

> Sloped window device

> Electronic angle display for sloped windows

> Industrial PC, with Windows PC control/NEXUS

Extraction nozzle diameter:

-----

Crosscut saw 80 mm

Slotting spindle 140 mm

Profile spindle 1 140 mm

Profile spindle 2 140 mm

Top grooving device 80 mm

Fitting spindle 120 mm

-----

Pr...

Listing

Germany

Germany

6,760 km

Window production centre

GUBISCHCW 2

Call

Condition: used, Year of construction: 1998, Tenoning spindle 1 St.

Number of milling agregates 4 St.

Spindle diameter 50 mm

1 GUBISCH – CENTROMAT CW 2

will be sold on behalf of our customer, ex location

-----

Manufacturer description:

-----

For window and door production, with 50 mm spindle diameter in

longitudinal profiling. With the following processing stations and options:

- Slotting machine on one side for straight and angled connections Milling

machine

for longitudinal profiling

- Rebating operation with synchronous milling unit and automatic plunge.

Pivoting frame support up to 650 mm

- Central control

1.0 cross-cut saw automatically plunges from above

-----

Motor power, including motor brake: 3.0 kW

Spindle speed: 2,800 rpm.

Cutting circle diameter: 350 mm diameter

Spindle diameter: 30 mm diameter

Clamping flange, 1 driver 6 mm diameter TK 42, 120 mm diameter

Pneumatic vertical stroke: 100 mm

Pneumatic horizontal stroke: 160 mm

against 2 manually adjustable 6-way turret stops

Chip extraction hood with extraction nozzle 100 mm diameter

2.0 slot unit

-----

Motor power, including motor brake: 9.2 kW

Spindle speed: 3,800 rpm

Flight circle diameter: 320 mm diameter

Spindle diameter: 50 mm diameter

Usable spindle length: 320 mm

Pneumatic vertical stroke fixed: 2 x 100 mm

Suitable for 3 tool sets of 100 mm each

Zero height: 10 mm

Kdsdsw I Eawjpfx Adwog

Chip extraction hood with extraction nozzle: 160 mm diameter

3.0 Slotting table

-----

Table height above floor 920 mm

Feed for 4 speeds freely adjustable:

- 1. Milling, slanting window and typing speed can be set in the table

(approx. 7 m/min.)

- 2. Sawing speed approx. 7 m/min. (can be set on the device)

- 3. Transfer speed approx. 10 m/min. (can be set on the device)

- 4. Return speed/without processing approx. 25 m/min. (can be set on the

device)

- Motor power, including motor brake 0.37 kW

Workpiece clamping pneumatic Pendulum pressure shoes

Workpiece clamping pneumatic

1 clamping cylinder with 2 additional pressure shoes

3.1 Counter wood device Counter wood changer with 2-way automatic change and

then with manual. Rotation of 180 degrees, 2 further counters possible, which

then

also counter in automatic mode

3.2 Length stop

-----

- Stop system with 3 scales for

- a) outside frame

- b) outside sash upright

- c) outside sash crosswise Adjustment manually

- Length with attachable extension 3000 mm

- for sloped windows, pivotable +/- 60 degrees 3.3 Angle transfer -

automatic via vertically clocked feed roller in the milling feed

4.0 Milling machine For longitudinal profiling and rebating of windows/doors

with

the following units:

-----

4.1 First profile milling unit

-----

- Counter-rotation

- Synchronous rotation with automatic plunge can be used for rebating

- Motor power including motor brake: 9.2 kW

- Spindle speed: 6000 rpm.

- Cutting circle diameter: 240 mm max.

- Spindles adjustable for zero diameter 140 mm max.

- of tools 112 mm min.

- Zero height: 10 mm

- Spindle diameter: 50 mm diameter

- Spindle usable length: 320 mm

- Vertical stroke pneumatically fixed,

- suitable for 4 tool sets of 80 mm each, 3 x 80 mm

- Horizontal stroke pneumatic: 80 mm

- Chip e...

Listing

Oberkochen

Oberkochen

6,774 km

Window production centre

WEINIGUnicontrol 10 NC

Call

Condition: used, Tenoning spindle 1 St

Number of milling agregates 4 St.

Spindle diameter 50 mm

Control Weinig, PC-Nexus

Weinig Unicontrol 10 CNC - Spindles radially and axially CNC-controlled

-----

The machine was factory overhauled by Weinig in 2024.

The control system was also upgraded to a Siemens S 7 677 C,

with a new membrane panel "Touch".

With the following machining units:

Crosscut saw

-----

with laser alignment light, motor power 3 kW, spindle diameter 40 mm,

spindle speed 3,000

Axially adjustable via NC axis

Radial pneumatic adjustment to 8 positions for edge rounding from above

Unit from below for edge rounding

-----

Axially adjustable with crosscut saw

Tenon and slotting spindle

-----

Motor power 15 kW

Spindle diameter 50 mm

Spindle speed 2,925 rpm

Tool travel radius min. 380, max. 400 mm

Tool clamping length 640 mm

Axially adjustable CNC axis

Axially adjustable travel 580 mm

Adjustment speed 100 mm/sec.

1. Profile spindle (up- and down-rotation)

-----

Motor power 11 kW

Spindle diameter 50 mm

Spindle speed 6,000 rpm

Tool clamping length 400 mm with counter bearing

Axially and radially adjustable via CNC axis

2. Profile spindle

Ksdoxpi Dujpfx Adwedg

-----

Motor power 11 kW

Spindle diameter 50 mm

Spindle speed 6,000 rpm

Tool clamping length 400 mm with counter bearing

Axially and radially adjustable via CNC axis

Profile milling unit horizontally mounted on top

-----

Motor power 3 kW

Spindle diameter 40 mm

Spindle speed 9,000 rpm

Pneumatically adjustable to 8 axial and radial positions

Profile milling unit vertically mounted on the right side Machine end

-----

Motor power 3 kW

Spindle diameter 40 mm

Spindle speed 5,850 rpm

Pneumatic adjustment to 8 axial and radial positions

Additional accessories

-----

CNC-controlled length stop, mounted on the slotting table

for lengths up to 3,500 mm, including a positioned cross-cutting saw integrated into the control system.

Studio window device, pivots 60° on both sides

Double-part package with automatic separation and transfer

Synchronization device with automatic window rebating

Rebating carriage for rebating small sash widths

Air conditioning unit in the control cabinet

PC control NEXUS

Automatic turning system

Slat conveyor, including conveyor belt for

returning the workpieces to the operator

(Technical specifications according to the manufacturer - without guarantee).

Trust Seal

Dealers certified through Machineseeker

Listing

Hermaringen

Hermaringen

6,761 km

Machining center

MAKAHC-55-TBZ

Call

Condition: used, Year of construction: 2000, Used machine

MAKA CNC Door Processing Center HC 55 TBZ

Year of manufacture: 2000

CNC machining center for processing interior doors (hardware mortising, vision panel cut-outs, peephole machining, etc.)

Kdedpov S Dn Dsfx Adwjg

CNC control BWO 900C, with 1 MB memory, integrated PC.

Working ranges:

For door width: 250 – 1,280 mm

For door height: max. 2,500 mm

For door leaf thickness: max. 80 mm

Rapid traverse speed:

X / Y-axis: 45 m/min

Z-axis: 10 m/min

1 universal milling unit SK40

With integrated A-axis swivel 190° (+/- 95°), along X-axis for lock/hinge machining on both sides along the longitudinal door edge directly with the unit.

Water-cooled milling spindle, nominal output 8 kW, available from 7,000 rpm, continuously variable speed from 1,000 – 17,100 rpm, SK40 tool holder for automatic tool change.

1 chain-type tool magazine with 24 positions, for tools up to Ø 90 mm, for sorted storage up to max. Ø 160 mm, positioned at unit’s service position. Max. tool length 200 mm from spindle mount.

Milling spindle and 2 x magazine positions equipped for angle/feeler heads with torque support.

Machine table with width adjustment via program, as well as width measurement for edge processing for consistent milling depth on both sides.

1 set of infeed rollers for manual loading, automatically elevating and lowering.

1 longitudinal stop with pneumatic insertion stroke, mounted on the traversing unit for positioning according to door length and thickness.

4 pneumatic lateral stops, swing-in type, for doors with veneer/cover overhang up to max. 15 mm, with selectable height adjustment for varying stop heights on finished doors (single/double rebate doors).

2 vacuum clamping lines, 5 vacuum suction cups per line, 130/200 x 70 mm, with touch valve and blow-off device. Per line, 3 vacuum cups can be lowered according to the door height being processed.

1 vacuum pump, approx. 128 m³/h suction capacity, with 250-liter intermediate tank, enabling rapid vacuum build-up.

Automatic central lubrication, free-standing control cabinet with air conditioner.

Safety features: Bumper on both sides of the gantry, protective fencing on the sides.

Various tools and tool holders can be taken over by agreement.

The machine can be inspected in Hermaringen.

Listing

Aalen

Aalen

6,772 km

Glazing bead sww

RUCHSERRU-GL-45°

Call

Condition: new, Number of motors 2 Stück

0 2380 mm

Control ,

RUCHSER RU-GL-45°

-----

Glass bead saw on the sliding work table

Developed for cutting glazing beads in pairs on the sliding work table

The RU-GL glazing bead saw is mounted on a sliding work table

Scanning and clamping device for

two glazing beads. Cutting length min. 230 mm, max. 2380 mm. Left saw fixed,

right saw on carriage

Manually movable mounted. Pneumatic clamping device from above and from

the side, safety two-hand operation. Saw motors 0.37 kW, voltage 400V.

Sliding work table with felt pad, length with side shelf 3300 mm,

Width 1400 mm, working height 800 - 1000 mm. Pneumatically lowerable

Counter bearing for positioning the wings.

Pos. 1: RU-GL double glazing bead saw 45° on RU-SA-3000

-----

for glazing beads up to 30 x 70 mm (W x H)!!!,

Mounted on the sliding work table with scanning and

Clamping device for two glazing beads.

Cutting length min. 230 mm, max. 2380 mm.

Left saw fixed, right saw on carriage manually

mounted movably.

Pneumatic clamping device from above and from

the side, safety two-hand operation.

Saw motors 0.37 kW, voltage 400V.

Sliding work table with felt pad, length with

side shelf 3300 mm, width 1400 mm,

Working height 800 - 1000 mm. Pneumatically lowerable

Counter bearing for positioning the wings.

-----

Basic price in the above version: on request!

-----

Ex works. Plus packaging and shipping as well as current

Material cost surcharge of 6% of the total price

Options with additional costs:

-----

Item 1.1 1 set of carbide saw blades for

for glazing bead saw RU-GL

D = 200 mm, 64 teeth, consisting of 1 piece each

Saw blade L1233 (left) and L1085 (right),

with special grinding 43°.

Additional price: 421.00 euros

Pos. 1.2 Holding device for scanning gauge

RU-GL for transferring the scanning dimensions to the saw

with pneumatic installation.

Additional price: 611.00 euros

Pos. 1.3 Measuring gauge for glazing beads, total length

2550 mm, max. scanning length approx. 2450 mm

Measuring gauge made of square profile with 2 fixed and

2 adjustable cams for measuring the length of the glazing beads

Additional price: 478.00 euros

Pos. 1.4 Measuring gauge for glazing beads, total length

1500 mm, max. scanning length approx. 1430 mm

Measuring gauge made of square profile with 2 fixed and

2 adjustable cams for measuring the length of the glazing bead

Additional price: 428.00 euros

Item 1.5 Set of inserts for rebated glazing beads

for RU-GLS-P45° and RU-GLS-ED45°

Price request, after checking the glazing beads.

Depending on the number of glazing beads used, this can happen

several sets of inserts are required. To determine the exact number

In order to be able to do this, we need profile drawings before order confirmation

the glazing beads to be used.

Additional charge: on request, after sending your glazing bead drawings

Pos. 1.6 Operating time switching device for

independent suction.

Adjustable from 5 seconds. up to 3 hours. With every sawing process

automatically becomes the set time

sucked off. Will be used again within the suction time

sawn, the set suction time begins

again from the beginning.

Kodpfx Adoxmkz Newedg

Additional price: 702.00 euros

-----

Total price i...

Listing

Cantù

Cantù

6,845 km

Moulder

CASADEISYNCRO

Call

Condition: good (used), Code: 0441

Kdsdpfx Adeu Tqm Rjwog

Brand: CASADEI

Model: SYNCRO

Four side straightening planer with 4 spindles for wood, window frames, furniture, garden furniture, sawmill and various

Technical data:

One-piece steel base

Min/max working width mm 20/180

Min/max working height mm 6/105

Infeed table length mm 2000

Infeed table and fence adjustment mm 10

Spindles diameter mm 35

Feeding speed 6/12 mt/min

Rebating cutterhead diameter mm 120

Powered feeding siystem raise

Composition:

1° Spindle surface planer - Motor Hp 10 - Size mm 190 x 100 Z3

2° Spindle right spindle moulder - Motor Hp 7,5 - Size mm 120 x 100 Z3

3° Spindle left spindle moulder - Size mm 120 x 100 Z3

4° Spindle thickness planer - Motor Hp 10 - Size mm 190 x 100 Z3

Diameter of suction ports mm 120

N° 4 Planer heads

Overall dimensions mm 3000 x 1160 x 1555 h

Weight kg 900

Listing

Oberkochen

Oberkochen

6,774 km

4 side moulder

WEINIGVariomat_Multifunktionstisch

Call

Condition: used, Number of spindles 5 St.

Working width 20 - 230 mm

Working height 8 - 120 mm

Length of the planing table 2000 mm

Feed motor 1,1 kW

Feed speed stufenlos regelbar 2 - 12 m/min.

1 WEINIG VARIOMAT planer and moulder including multifunction / slotting table

-----

Machine will be cleaned and functionally tested before delivery !

Technical manufacturer's description:

-----

Working width: 20 - 230 mm

Working height: 8 - 120 mm

1st spindle horizontal, bottom

-----

Motor with brake: 5.5 kW

Diameter 40 mm

Speed ??6000 rpm

Tool radius 125 - 145 mm

Axis adjustment range 5 mm

Folding device including rebate cutter

MarathonCoating for table insert before and after the 1st lower spindle

2nd spindle vertical, right

-----

Motor with brake: 11 kW

Common motor with left vertical spindle

Diameter 40 mm mm

Speed ??electronically adjustable 3000 - 6000 rpm (for 11 kW/15 HP)

Tool cutting radius for longitudinal machining 93-232 mm

Minimum tool diameter at stop plane: 93 mm

Maximum tool diameter behind stop plane: 180 mm

Maximum throat depth 45 mm

Axially adjustable travel 30 mm

Insertion segment, including additional stop lip 125 mm

Insertion segment, including additional stop lip 150 mm

3rd vertical spindle, left POWERLOCK/HSK

-----

Shared motor with 1st right spindle

PowerLock tool holder

Shared speed with right vertical spindle

Tool cutting radius for longitudinal machining 93-232 mm

Maximum throat depth 45 mm

Minimum throat depth with tool cutting radius 200 mm: 20 mm

Axially adjustable travel under table 30 mm

Insertion segment 125 mm

Insertion segment 150 mm

4th spindle, horizontal, top

-----

Motor with brake: 5.5 kW

Diameter 40 mm

Speed ??6000 rpm

Tool cutting radius 125-200 mm

Maximum chamfering depth 30 mm

Minimum chamfering depth with a tool cutting radius of 200 mm: 20 mm

Axially adjustable range 30 mm

Glazing bead removal after the upper spindle

5th spindle, second, horizontal, bottom

-----

Motor with brake: 4 kW

Diameter 40 mm

Speed ??6000 rpm

Tool cutting radius 125-200 mm

Maximum chamfering depth 15 mm

Axially adjustable range 10 mm

Machine operation

-----

Both axes of all spindles - with the exception of the first lower spindle - are

equipped with

mechanical digital displays.

Central radial adjustment with mechanical digital display of the feed rate

along with the pressure in front of the upper spindle.

The pressure after the upper spindle can be adjusted separately.

Memory function

-----

For saving the setting values ??of profiles

Tool holder axes and pressure elements before and after the upper

tool holder with electronic dual displays:

Function:

-Saving the setting values ??of the finished profile at the touch of a button

under a

profile number

- When the profile number is selected again, the electronic dual displays

show the setting values

- By manually adjusting the tool holders and pressure elements,

Kdjdpfx Adewugpbewog

the displays are aligned

- 99 memory locations

3 axial CNC-controlled adjustment and positioning of the spindles

in conjunction with the memory function. For spindles 2, 3, an...

We make it easier for you to find: "rebating"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Rebating (65)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you