Used Sound Enclosure for sale (2,093)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Radom

Radom

6,026 km

Folding machine

Horizon PF P-330Folding Machine with Base

Call

Condition: good (used), Horizon PF P-330 Folding Machine with Base

The machine is in very good condition and 100% functional.

This folding machine is ideal for digital printing. Quick and easy to set up – automatic cassette adjustments and paper size detection. A huge advantage is the vacuum feed – a compressor is included.

The machine handles all types of paper perfectly.

Nedpfsx A Sctex Adwecl

Made in Japan.

Technical specifications:

Minimum format: 125 x 130 mm

Maximum format: 310 x 432 mm

Paper weight: 40 to 180 g/m²

Infeed stack height: 50 mm

Six folding options: half-fold, quarter-fold, Z-fold, C-fold, altar-fold, etc.

Folding speed: 200 sheets/min per hour, 12,000 sheets/h

Dimensions: 1060 x 553 x 670 mm

Weight: 45 kg

Power supply: 230V

The machine includes: an external compressor in a sound-absorbing enclosure, an instruction manual, and a large-format accessory.

Listing

Kehra

Kehra

6,028 km

Moulder

WEINIGHYDROMAT 1000 + MECHANISATION

Call

Condition: excellent (used), Year of construction: 2012, Weinig H1000 moulder with E3 infeed and A3 outfeed mechanisation

Weinig Hydromat 1000 with 5 Spindles. (Year 2012)

Separate electrical panel

Separate remote control panel

Automatic lubrication system for bedplates

Memory system

Full sound enclosure

Weinig E3 moulder infeed +pack scissors lift (3000kg).

Weinig A3 drop leaf outfeed + pack scissors lift (3000kg) + pack outfeed chain conveyor.

Ncsdpex Rbkxjfx Adwol

WEINIG HYDROMAT 1000

230X160mm maximum dimension

No 1. 7.5kw - Bottom 6000rpm + Outboard bearing + Straight jointer

No 2. 7.5kw - Right 6000rpm + profile jointer

No 3. 7.5kw - Left 6000rpm + profile jointer

No 4 . 7.5kw - Top 6000rpm + Outboard bearing + Straight jointer

No 5 . 7.5kw - Bottom 6000rpm + Outboard bearing + Straight jointer

50mm spindles

Beam 0.55kW

Full documentation included.

Extraction manifold included.

POSSIBLE TO PURCHASE MOULDER OR MECHANISATION SEPARATELY AS NEEDED

Listing

Kehra

Kehra

6,028 km

Moulder

WeinigHydromat 1000 (5S)

Call

Condition: excellent (used), Year of construction: 2012, Weinig H1000 moulder

Weinig Hydromat 1000 with 5 Spindles. (Year 2012)

Separate electrical panel

Separate remote control panel

Automatic lubrication system for bedplates

Memory system

Full sound enclosure

No 1. 7.5kw - Bottom 6000rpm + Outboard bearing + Straight jointer

No 2. 7.5kw - Right 6000rpm + profile jointer

No 3. 7.5kw - Left 6000rpm + profile jointer

No 4 . 7.5kw - Top 6000rpm + Outboard bearing + Straight jointer

No 5 . 7.5kw - Bottom 6000rpm + Outboard bearing + Straight jointer

50mm spindles

Beam 0.55kW

Full documentation included.

Extraction manifold included.

Possible to supply with Weinig mechanisation if needed (Year 2012)

Nodpfx Ajx N T Nqsdwecl

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Kehra

Kehra

6,028 km

Moulder

WEINIGHYDROMAT (8 spindle)

Call

Condition: good (used), Weinig Hydromat H23 8 spindle

50mm spindles 6,000 RPM

Bottom 7.5kW jointer ready

Right 7.5kW straight jointer ready

Left 15kW straight and profile jointer ready

Right 11kW profile jointer ready

Ncodex N T Iyjpfx Adwsl

Top 15kW jointer ready

Bottom 18.5kw jointer ready

Top 11kw straight and profile jointer ready + outboard bearing

Bottom 7.5 kw straight and profile jointer ready + outboard bearing

7.5kW feed motor.

Automatic lubrication system.

Full heavy duty sound enclosure

Possible to supply with moulder infeed and outfeed as needed.

Possible to offer tooling if needed.

Listing

Kehra

Kehra

6,028 km

Moulder

WeinigHydromat 23C 100m/min

Call

Condition: excellent (used), Weinig Hydromat 23C with 6 Spindles.

Max width 245mm

Max Thickness 160mm

Separate electrical panel.

Separate remote control panel

Automatic lubrication system for bedplates

Full heavy duty sound enclosure.

15kW feed motor 100m/min

No 1. 7.5kw - Bottom 6000rpm straight jointer prepared

No 2. 11kw - Right 6000rpm straight and profile jointer prepared

No 3. 15kw - Left 6000rpm straight and profile jointer prepared

No 4 . 15kw - Top 6000rpm + Outboard bearing + straight and profile jointer prepared

No 5 . 30kw - Top 6000rpm + Outboard bearing + straight and profile jointer prepared

Njdpfsx N T Imox Adwscl

No 6 . 15kw - Bottom 6000rpm + Outboard bearing + straight and profile jointer prepared

50mm spindles

Beam 0.55kW

Full documentation included.

Heavy duty sound enclosure.

Possible to supply with hydro tooling if needed.

Possible to supply with full mechanisation if needed.

Listing

Haps

Haps

7,078 km

Suction vehicle

MANTGS 35.400 8X2-4 BL WIEDEMANN SUPER 1000

Call

Condition: excellent (used), mileage: 1,33,000 km, power: 294 kW (399.73 HP), first registration: 12/2016, fuel type: diesel, axle configuration: 8x2, fuel: diesel, brakes: engine braking, color: blue, driver cabin: day cab, gearing type: mechanical, number of gears: 16, emission class: euro6, total length: 11,610 mm, total width: 2,550 mm, total height: 3,700 mm, loading space volume: 15 m³, Year of construction: 2016, Equipment: ABS, air conditioning, central locking, cruise control, electric window regulation, fog lights, navigation system, power mirror, - Brake booster

- Remote-controlled central locking

- Refrigerator

- Air suspension

- Air horn

- Radio/CD player

Njdpfxox Tvn Rj Adwjcl

- Reversing camera

- Sun visor

- Toolbox

- Xenon lighting

- Central lubrication

Manufacturer: WIEDEMANN

Model / Sales designation: SUPER 1000 15

Equipment number: D/BAM/1666/T

Factory No.: X OW 1000 1494

Year of manufacture: 02.12.2016

Equipment: Suction / pressure tank body

ADR

Sludge compartment – variable size, rear closure floor and front torispherical head made from stainless steel, material 1.4404, sludge tank in stainless steel, material 1.4404, auxiliary tipping device, sludge tank lid/ADR, sludge tank lid – hydraulically opening, central locking pneumatically operated, level indicator with scale at the tank bottom, lower suction connection with gate valve DN 125 reduced to DN 100, lower suction connection pneumatically actuated, upper suction connection with gate valve DN 125 reduced to DN 100, hydraulic telescopic piston, display of 3 pre-set piston positions, ADR equipment, tank code L4BH (without heat recovery), splash partition in stainless steel 1.4301, vacuum pump type CVS VACUSTAR 1600 – DN 100, overfill protection, vacuum pump cooling, oil separator and silencer, vacuum pump flushing device, vacuum system piping, safety fittings and fittings DN 125, suction hose reel 25 m DN 125, special spiral suction hose 25 m / DN 125, oil-resistant, transport hose reel 40 m DN 80 (side-mounted), suction and high-pressure (HP) boom, retractable suction and HP boom, water compartment – variable, water filling device, hand washing device, warm, level control – Plexiglas sight glass for water compartment, high-pressure pump type URACA P 345-60, HP system protection, high-pressure reel 220 m DN 25 or 180 m DN 32, at the boom, high-pressure hose 180 m DN 25, rubber (GrüloKan 250), large automatic winding device, pressure roller – large HP reel, meter counter, high-pressure reel 80 m DN 13, hydraulic, high-pressure hose 80 m DN 13, rubber (GrüloKan 250), water shortage protection, pneumatic system, three-stage hydraulic system, centralized lubrication system, hydraulic winch, electrical system, reversing camera system with 2nd camera, engine can be started from control panel, PLC/CAN-BUS control, control cabinet with display, radio remote control with display, equipment cabinet with single flap – one side, insert tubes for suction hoses, pump room sound enclosure, full side paneling, toolbox approx. 800x500x500 mm, stainless steel, 3 work lights (LED), 2 revolving warning lights – flashing version, operating hour meter for HP pump; operating hour meter for vacuum pump, compressed air connection, spring cable pull, ladder, ladder holder, shovel, broom, and manhole hook

Next inspection dates:

General inspection (HU): 01 / 2026

Section 57b test: 05 / 2025

Safety inspection (SP): 07 / 2025

GGVSEB/ADR inspection: 02.01.2026

Tank inspection: 12 / 2027

German registration

In very good condition!

Immediately operational

Transmission

Transmission: ZF, 16-speed manual transmission

Axle configuration

Front axle 1: steered

Front axle 2: steered

Rear axle 1: steered

Weights

Unladen weight: 21,952 kg

Payload: 10,048 kg

Gross vehicle weight: 32,000 kg

Functionality

Body make: Wiedemann Super 1000...

Listing

Borken

Borken

7,009 km

Temperature test chamber

CTSTSR-30/1000

Call

Condition: good (used), CTS

Type: TSR-30/1000

Water-cooled

The type designation of the CTS enclosure series is made up as follows:

z. e.g. type TSR -30/1000

1) T means: Temperature

2) S means: stress screening

3) R means: external conditioning

4) -30 means: lower temperature -30 °C

5) 1000 means: 1000 liter test chamber volume

Technical performance data:

A) TSR-30/1000 basic device without hose connections,

i.e. when used as a stand-alone temperature test chamber

Temperature tests:

Temperature range -40°C to +180°C

Final temperature -45°C

Temperature deviation ≤ ±0.3 K in time

Temperature change rate according to IEC 60068-3-5

Heating 6.0 K/min

Cooling 5.0 K/min

Heat radiation

approx. 5000 W at +20°C

approx. 4200 W at ± 0°C

approx. 3000 W at -20°C

The technical data refer to an ambient temperature of +25 °C,

rated voltage 400V, without test material, without irradiation and without additional equipment.

Air volume flow

approx.2000m³/h

B) TSR-30/1000 basic unit with hose connections,

for connection to an external test room provided by the customer

Temperature tests:

Temperature range -30°C to +170°C

Temperature deviation ≤ ±0.1 to 0.5 K in time

Average rate of temperature change,

measured with short-circuited circuit

Heating 4.0 K/min

Cooling 4.0 K/min

in the range from +150°C to -10°C

The technical data refer to an ambient temperature of +25 °C,

rated voltage 400V, without test material, without irradiation and without additional equipment,

measured with short-circuited circuit

Attention: The external test chamber provided by the customer must be absolutely tight and appropriately insulated,

any feed-throughs must be optimally sealed on site.

Dimensions:

Test volume 1000 liters

Air circulation connection Ø 200 mm

Test chamber dimensions Height 900 mm Width 1000 mm Depth 1100 mm

External dimensions Height 1950 mm Width 1270 mm Depth 2245 mm

Technical design:

Refrigeration unit:

water-cooled, low-noise, fully hermetic

Ncodpfxerivfcs Adwol

Infinitely variable capacity adjustment through

electronic monitoring and control system,

environmentally friendly refrigerant R404A

Door:

Fully opening door, door hinge on the left,

one-handed operation, lockable.

Shelf:

Stainless steel, support surface 970 x 980 mm

Max. load per shelf 35 kg

Total load with max. shelf load 100 kg

Test area lighting: Halogen lamp 20 W, 12 V

Control:

- 32 bit controller

- LCD control panel

Operating data:

Electrical connection 400 V +6/-10 %, 3/N, 50 Hz

Rated power 13.3 kW

Protection class IP 22

Sound pressure level < 60 dB(A)

Weight approx. 850 kg

The following information is for your safety as a buyer!

The following points are carried out on our offered chambers in advance:

1. functional check and replacement of necessary components

2. if necessary, refilling with legally compliant refrigerant

3. leak test with certificate

4. after successful inspection, the chambers are subjected to a documented test run.

Condition: used

Scope of delivery: (see picture)

(Changes and errors in the technical data, specifications are reserved!)

We will be happy to answer any further questions you may have on the phone.

Listing

Trondheim

Trondheim

6,910 km

Double end tenoner

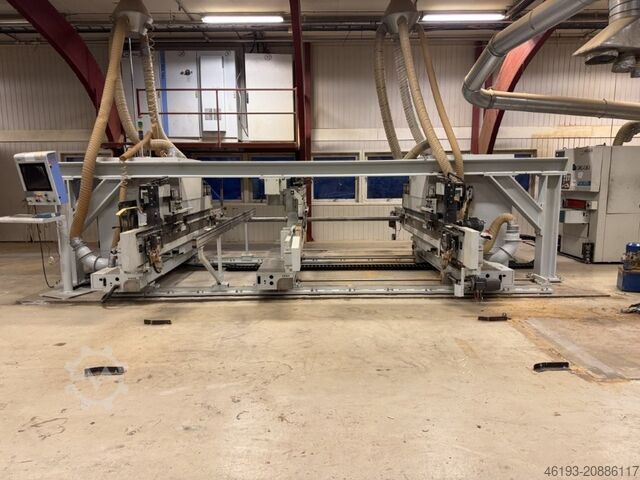

HOMAGFPL 626/03/40/W/3K

Call

Condition: ready for operation (used), Year of construction: 2009, functionality: fully functional, Equipment: documentation/manual, HOMAG FPL 626/03/40/W/3K

Double-sided HOMAG format processing machine for solid wood flooring in cross-feed through-feed operation.

Ncodox Spxgspfx Adwjl

Fixed reference side left, movable side right .

Technical data:

Feed speed, infinitely adjustable: 10–40 m/min

Format overhang: 3 mm (note profile depth)

Format thickness: 10–23 mm

Format length in front of lugs: max. 140–250 mm

Infeed length min: 2,400 mm

Infeed length max: 4,000 mm

Working height to top of chain: 950 mm

Pneumatic connection: 7–8 bar

Standard Milling Unit SF20, 6.6 kW – Format Section - F.01 (1323) - 1 × left, 1 × right

For grooving and rebating from the top/bottom as well as from the side, in counter-rotation.

• 1 milling motor, 6.6 kW, 100 Hz, 6,000 rpm

• Motor shaft Ø35 × 70 mm with keyway

• Swivel range: 90°, manual

• Cross-slide with electro-pneumatic control for plunge milling

• Directional switch for rotation direction

• Extraction hood

• Groove position: minimum distance 10 mm from chain track or top pressure

• Maximum tool diameter: 200 mm

• Without tools

• Electronic frequency inverter with motor braking function

• Manual horizontal and vertical adjustment via spindle and counter

Free Space for additional milling unit - 715 mm – Standard Milling Unit - F.04 (1318) - 1 × left, 1 × right

• Including extension of sound enclosure and extraction connection ports

• Without electrical pre-installation

FOR MORE TECHNICAL SPECIFICATION PLEASE READ ATTAGED DOCUMENTS in PDF format.

This machine stands in south Norway on it orginal place. The company is now closed but it is possible to inspect the machine.

Rekman Maskin & Service since 1986

Listing

Weeze

Weeze

7,055 km

Planer

Rhino XL800XL800

Call

Condition: used, Year of construction: 2018, functionality: fully functional, planing height: 230 mm, planing width: 320 mm, FEM9-32XC / RHINO 800XL Feeler-series 9

FEELER series

A. Capacity:

(1) Working width: 18–320 mm

(2) Working thickness: 6–160/230 mm

(3) Minimum working length: 240 mm

(4) Feed speed: 7–36 m/min

B. Motor:

(1) 1st bottom horizontal spindle: 10/20 HP with outboard bearing

(2) 2nd right vertical spindle: 10/15 HP with outboard bearing

(3) 3rd left vertical spindle: 10/20 HP with outboard bearing

(4) 4th top horizontal spindle: 10/20 HP with outboard bearing

(5) 5th bottom horizontal spindle: 10/20 HP with outboard bearing

(6) 6th right vertical spindle: 10/15 HP with outboard bearing

(7) 7th left vertical horizontal spindle: 10/15 HP with outboard bearing

(8) 8th top horizontal spindle: 10/20 HP with outboard bearing

(9) 9th bottom horizontal spindle: 10/20 HP with outboard bearing

(10) Feed drive: 15 HP (Inverter)

(11) Elevation: 2 HP

C. Spindles:

(1) Spindle diameter: 50 mm for 1st, 2nd, 3rd, 4th, and 9th spindles; 40 mm for 5th, 6th, 7th, and 8th spindles

(2) Spindle cutting speed: 6200 rpm

(3) Adjustment range, vertical spindle: 80 mm

(4) Adjustment range, horizontal spindle: 35 mm

D. Cutting circles:

(1) 1st bottom horizontal spindle: 100–180 mm

(2) Right vertical spindle: 110–250 mm

(3) Left vertical spindle: 110–250 mm

(4) 1st top horizontal spindle: 110–250 mm

(5) 2nd bottom horizontal spindle: 110–250 mm

(6) Right vertical spindle: 110–250 mm

(7) Left vertical spindle: 110–250 mm

(8) Top horizontal spindle: 110–250 mm

(9) Bottom horizontal spindle: 110–250 mm

E. Miscellaneous:

(1) Dust extraction port diameter: 160 mm

(2) Infeed table: 2–2.5 m

(3) Feed roller diameter: 140 mm

(4) Includes 50 mm cutterhead

F. Standard Equipment:

(1) Digital feed speed display: DPRLF-40K

(2) Automatic table lubrication system

(3) Centralized point-to-point lubrication

(4) Pneumatic chip breakers on top spindles

(5) Pneumatic fence on left spindles

(6) CE marking

(7) Motor: IE3

(8) Sequence: Bottom, Right, Left, Top, Bottom, Right, Left, Top, Bottom

Options:

• OP014-15 Variable Feed Speed Controller, 15 HP inverter

• OP001 Pneumatic control for 1st and 2nd elevation infeed roller

Njdsxrla Repfx Adwscl

• OP041 Outboard bearing for 2nd, 3rd, 6th, and 7th spindles

• OP017 Digital position controller for 3rd, 4th, 7th, and 8th spindles

• OP042C Enhanced sound enclosure

• OP023AE3-15 Feed motor, 15 HP (E3)

• OP023BE3-10-15 Motor for 10/15 HP spindle (Y/A, E3)

• OP008-5 Extension table, 2.5 m with stand and fence

• OP023BE3-10-20 Motor for 10/20 HP spindle (YiA, E3)

• OP002 Three-mode feed roller pneumatic elevation

• OP010-230 Extra working height 230 mm for 2nd, 3rd, 6th, and 7th spindles

• OP008A Air cushion table, 320–400 mm

This translation uses precise, industry-standard terminology suitable for specialized machinery listings.

Listing

Roreto

Roreto

6,951 km

Double-End TENONER (High-speed)

HOMAGProfiline FPL 526/4/25

Call

Condition: good (used), Independent machine (standing alone) and/or Universal machine (First & Second in a line)

Numerical Control Power Control 22, Software WoodCommander (Windows)

Safety and sound-proof enclosure

No. 2+2 Vertical columns to support the working units

Min. useful working width (mm) 155

Max. useful working width (mm) 2500

Min. useful working tickness (mm) 12

Ncedjdh Tfkspfx Adwsl

Max. useful working tickness (mm) 60

Max. depth of the panel for automatic infeed (mm) 1200

Distance between center-axes of the disappearing dogs (mm) 500

Adjustable (min/max) feeding speed (m/min) 10 - 30

No. 4 Working groups (for each machine's side):

1 Vertical milling Unit (Anti-chipping) 1 x Kw 4,5

2 Hogging Units (KD 11) 2 x Kw 6,6

1 Fine trimming unit (0°-25°) 2 x Kw 0,4

Listing

Roreto

Roreto

6,951 km

Double-side SIZING & EDGE BANDING machin

IMACombima /II/230/A/R3

Call

Condition: reconditioned (used), Double-side Sizing-Milling & Edge Banding - First (1st) machine in a line

Edges (band in rolls) thickness (Min/Max) mm 0,3 / 3

Panels thickness (min/max) mm 8 / 45

Working width (min/max) mm 236 / 1300

Numerical Control /Software ICOS Open

Adjustable feeding speed (m/min ) 10 / 50

Without Transmission bar (Master & Slave system)

Safety and sound-proof enclosures/cabins

SIZING PART (for each side):

Spraying unit (Anti-sticking liquid)

Milling Unit (vertical Joint Trimmers) 08. 0555 max. 3° (2 x 1 kW)

Free space

EDGE-BANDING PART (for each side):

Glueing Unit (Hot Melt Glue + Quick Melt system) 04.1570

Band Pressure zone

Edge coils supporting unit (reels N°) 6

Rough Trimming unit 08. 0555 (2 x 1 kW) max. 3°

Fine Trimming unit 08. 055 (2 x 0,66 kW) 30° + 30 m/min

Glue scraping unit 08.517

Spraying Unit (for polishing liquid)

Nodpfx Aodh Tfgodwjcl

Buffing unit 08.617-2 (2 x 0,18 kW)

Free space

Listing

Roreto

Roreto

6,951 km

Double-End TENONER - SCM

CELASCHI (SCM Group)Celaschi P 30

Call

Condition: excellent (used), Independent machine (standing alone) and/or Universal machine (First & Second in a line)

Electronic Programmer EasyLing

Safety and sound-proof enclosure

No. 3+3 Vertical columns to support the working units

Min. useful working width (mm) 240

Max. useful working width (mm) 3100

Min. useful working tickness (mm) 3

Max. useful working tickness (mm) 150

Distance between center-axes of the disappearing dogs (mm) 800

Adjustable (min/max) feeding speed (m/min) 4 - 24

Total installed power

Ncodpfx Aswhmdfodwol

No. 4 Working groups (for each machine's side):

Scoring Unit

Jumping Scoring Unit 1 x Kw 3 (RPM 6000)

Hogging Unit 1 x Kw 6 (RPM 6000) 0-10°

Jumping Milling Unit 1 x Kw 6 (RPM 6000) 0°-90°

Milling-Shaping unit 1 x Kw 6 (RPM 6000) 0°-90°

Listing

Roreto

Roreto

6,951 km

Double-side SIZING&EDGE BANDING machine

IMACombima Concept/II/B/R3

Call

Condition: excellent (used), Double side - Independent Machine (or 1st and/or 2nd in a line)

Edges (tape) thickness in rolls (min/max) mm 0,3 / 3

Edges thickness in stips / lippings (min/max) max mm 1,0

Panels thickness (min/max) mm 8 / 45 (60)

Working width (min/max) mm 236 (266) / 3300

Numerical Control / Software ICOS Open (Windows base)

Adjustable feeding speed (m/min ) 10 - 50

Safety and sound-proof enclosures/cabins

SIZING PART (for each side):

Anti-chipping Milling Unit 75.186 (1 x Kw 4,4)

Hogging Units (2 x Kw 6,6)

Free space

EDGE-BANDING PART (for each side):

Lamps to heat the workpieces side

Glueing Unit (Hot Melt glue) 04.1570

Nodpswz Ic Aofx Adwocl

Pressure zone

Edge coils supporting unit (No. of reels) 2

Snipping (end-cutting) unit 08.42 (2 x Kw 0,66) 30 m/min (0°-25°)

Rough Trimming unit 08.0555 (1 x Kw 0,66)

Multi Function Unit (Profile contour Trimming unit) MFA 08.342 (2 x Kw 0,66) SERVO - 20m/min

Profile Scraping unit 08.519

Glue scraping unit 08.50

Buffing unit 08.617-2 (2 x Kw 0,18)

Milling grooving unit: 75.30 (2 x Kw 4,4)

Listing

Roreto

Roreto

6,951 km

Double-side SIZING-EDGE BANDING Machine

HOMAGKFL 526 / 9 / A3 / 25

Call

Condition: excellent (used), Double side - Independent Machine (or 1st and/or 2nd in a line)

Edges (band in rolls) thickness (Min/Max) mm 0,3 / 3

Panels thickness (min/max) mm 12 / 60

Working width (min/max) mm 225 / 2500

Numerical Control PC 22 /Software WoodCommander

Adjustable feeding speed (m/min) 15 - 40.

Safety and sound-proof enclosures/cabins

Distance (center-axes) of the Disappearing Dogs (mm)

SIZING PART (for each side):

Spraying unit (Anti-sticking liquid)

Anti-chipping Milling Unit 1 x Kw 4,5

Hogging Units KD 11 (2 x Kw 6,6) . Free space

EDGE-BANDING PART (for each side):

Glueing Unit (P.U.R. Glue + Quick Melt unit) QA 34 (FeMa-Tech)

Pressure zone (N.C. adjustment) "A"

Edge coils supporting unit (No. of reels) 6

Snipping (end-cutting) unit HL84 (2 x Kw 0,22) 0°-30°

Rough Trimming unit (2 x Kw 0,55)

Multi-Profile Copying unit by N.C (fine and contour trimming) FK 13 (2 x Kw 0,4) revolver 8+8

Free space

Profile Scraping unit (Multi-profile, by N.C.) MN 21

Nodpfx Aewxwyfsdwocl

Finish processing unit (Glue scraper + Buffing unit) FA 11

OPTIONAL: Milling grooving unit UF11 (1 x Kw 4)

Listing

Roreto

Roreto

6,951 km

Double-side SIZING-EDGE BANDING Machine

HOMAGPROFI KF 20/09/QA/10

Call

Condition: excellent (used), Double side Sizing & Edge banding - First (1st) machine in a line

Edges (tape) thickness in rolls (min/max) mm 0,3 / 3

Panels thickness (min/max) mm 10 / 60

Working width (min/max) mm 240 / 1000

Nsdpfxoifnxxo Adwscl

Numerical Control / Software NC 21 / Homatic

Adjustable feeding speed (m/min ) high speed 10 - 60

Safety and sound-proof enclosures/cabins

SIZING PART (for each side):

Hogging Units KD 10 (2 x Kw 6,6)

EDGE-BANDING PART (for each side):

Glueing Unit (Hot Melt + Quick Melt Unit) A3 + A34 (high Speed package)

Pressure zone

Edge coils supporting unit (No. of reels) 2

Rough Trimming unit 2 x Kw 0,55

Fine Trimming unit 2 x Kw 0,55 (0° - 30°)

Finish processing unit (Glue scraper + Buffing unit) FA 11

Milling grooving unit UF11 (1 x Kw 4) 0°-90°

Listing

Roreto

Roreto

6,951 km

Double-side SIZING-EDGE BANDING Machine

IDM (SCM Group)Activa SB/1 (9900)

Call

Condition: excellent (used), Double-side Sizing-Milling & Edge Banding - First (1st) machine in a line

Edges (tape) thickness in rolls (min/max) mm 0,3 / 3

Panels thickness (min/max) mm 10 / 60

Working width (min/max) mm 230 / 1600 (ca.)

Numerical Control / Software WinEdge

Adjustable feeding speed (m/min ) 10 - 30

Safety and sound-proof enclosures/cabins

SIZING PART (for each side):

No. 2 Hogging Units (2 x Kw 5,8 ca.)

No. 2 Milling units (2 x Kw 4 ca.)

EDGE-BANDING PART (for each side):

Glueing Unit (Hot Melt glue + Multing Unit)

Pressure zone (adjustable by CN)

Njdpfxjl Hydms Adwocl

Edge coils supporting unit (No. 6 reels)

Rough Trimming unit (2 x Kw 1 ca.)

Fine Trimming unit 08.055 (2 x Kw 0,5 ca.) 0°-30°

No. 5 Milling grooving units (5 x Kw 4 ca.)

Profile Scraping unit

Glue scraping unit

Spraying Unit (for polishing liquid)

Buffing unit + Hot Air Heater (to reactivate the color of plastic tape)

Listing

Roreto

Roreto

6,951 km

Double-side SIZING-EDGE BANDING Machine

IMACombima II / 440 /A / R3

Call

Condition: excellent (used), Double-side Sizing-Milling & Edge Banding - First (1st) machine in a line

Edges (tape) thickness in rolls (min/max) mm 0,3 / 3

Panels thickness (min/max) mm 8 / 45 (60)

Working width (min/max) mm 250 / 1300

Numerical Control / Software ICOS Open (Windows base)

Adjustable feeding speed (m/min ) 10 - 50 (Master & Slave)

Safety and sound-proof enclosures/cabins

SIZING PART (for each side):

Hogging Units (2 x Kw 6,6) Max 35 m/min

Milling unit (joint Trimmer) 75.186 (1 x Kw 4,4)

Nodpoxggthefx Adwocl

EDGE-BANDING PART (for each side):

Glueing Unit (PUR. Glue + Quick Melt system + EVA Glue) VTG 3-24 + 283.201 + 283.19 + 283.203

Pressure zone

Edge coils supporting unit (No. 24 reels)

Rough/Fine Trimming unit 08.055 (2 x Kw 1) 0°-30° (30 m/min)

Rough/Fine Trimming unit 08.055 (2 x Kw 1) 0°-30° (30 m/min)

Profile Scraping unit 08.515

Glue scraping unit 08.521

Buffing unit 08.617-2 (2 x Kw 0,18)

No. 3 Grooving units 08.190 (2 x Left-hand + 1 x Right-hand) (Kw 4,5 x 3) swivelling 90°/180°/270°

Listing

Roreto

Roreto

6,951 km

Double-side SIZING-EDGE BANDING Machine

HOMAGKFL 525/6/A3/15

Call

Condition: excellent (used), Double side - First (1st) machine in a line

Edges (band in rolls) thickness (Min/Max) mm 0,3 / 3

Panels thickness (min/max) mm 12 / 60

Working width (min/max) mm 195 / 1500

Numerical Control PC 22 /Software WoodCommander

Adjustable feeding speed (m/min) 15 - 40

Safety and sound-proof enclosures/cabins

SIZING PART (for each side):

Nsdpfjwxwxbsx Adwecl

Spraying unit (Anti-sticking liquid)

Hogging Units KD 10 (2 x Kw 6,6)

Free space

EDGE-BANDING PART (for each side):

Glueing Unit (P.U.R. Glue + Quick Melt unit) QA 34 (FeMa-Tech)

Pressure zone (N.C. adjustment) Type "A"

Edge coils support (No. 6 reels)

Milling-grooving units SF 20 (HSK63F - Kw 4,5) 0°-90° CN Horizontal

Rough Trimming unit (2 x Kw 0,55)

Fine Trimming unit MF 21 (2 x kW 0,55)

Profile Scraping unit (Multi-profile, by N.C.) MN 21

Finish processing unit (Glue scraper + Buffing unit) FA 11

Listing

Roreto

Roreto

6,951 km

Double-side SIZING & EDGE BANDING machin

IMACombima II / 190 / B / R3

Call

Condition: excellent (used), Double side - Independent Machine (or 1st and/or 2nd in a line)

Nodpfjum Untex Adwscl

Edges (tape) thickness in rolls (min/max) mm 0,3 / 3

Panels thickness (min/max) mm 8 / 45 (60)

Working width (min/max) mm 236 / 1300

Numerical Control / Software ICOS Open (Windows base)

Without Transmission bar (Master & Slave system)

Adjustable feeding speed (m/min ) 10 - 50

Safety and sound-proof enclosures/cabins

"Hopper Feeder" (panels fall directly onto the feeding chains)

Distance (center-axes) of the Disappearing Dogs (mm) 270

SIZING PART (for each side):

Spraying unit (Anti-sticking liquid)

Anti-chipping Milling Unit 75.186 (1 x Kw 4,4)

Hogging Units (2 x Kw 6,6)

Free space

EDGE-BANDING PART (for each side):

Glueing Unit (Hot Melt + Quick Melt Unit) 04.1570 + 283.201

Pressure zone

Edge coils supporting unit (No. of reels) 6

Snipping (end-cutting) unit 08.42 (2 x Kw 0,66) 30 m/min (0°-25°)

Fine Trimming unit 08.055 (2 x Kw 0,66) 30 m/min

Glue scraping unit 08.521

Spraying Unit (for polishing liquid)

Buffing unit 08.617-2 (2 x Kw 0,18)

Free space

Listing

Roreto

Roreto

6,951 km

Double-side SIZING-EDGE BANDING Machine

STEFANI (SCM Group)Performance SB2

Call

Condition: excellent (used), Double side - Independent Machine (or 1st and/or 2nd in a line)

Edges (band in rolls) thickness (Min/Max) mm 0,3 - 3

Edges thickness in stips / lippings (min/max) option: mm 20

Panels thickness (min/max) mm 10 / 60

Working width (min/max) mm 250 / 3000 (ca.)

Adjustable feeding speed (m/min) 12 - 40 m/min (ca.)

Safety sound-proof enclosures/cabins

Distance (center-axes) of Disappearing Dogs (mm) 500

Ncsdpfxjk Nk R De Adwsl

SIZING PART (for each side):

Spraying unit (Anti-sticking liquid)

Anti-chipping Milling Unit (1 x Kw 4 (ca.))

Hogging Units (2 x Kw 5,8 (ca.))

Milling-Shaping unit 1 x Kw 4 (ca.)

EDGE-BANDING PART (for each side):

Glueing Unit (Hot Melt Glue + Quick Melt system)

Edge coils support (No 2 reels) + Band Pressure zone

Snipping (end-cutting) unit (2 x Kw 0,35) ca.

Rough Trimming unit (2 x Kw 1) ca.

Fine Trimming unit (2 x Kw 0,5 ca.) 0°-30°

Multi Function Unit (Profile contour Trimming unit) with 2 revolvers (8+8 folds) - max 27 m/min

Milling grooving unit 1 x Kw 4 (ca.) (0° - 90°)

Profile Scraping unit + Glue scraping unit + Buffing unit

Listing

Roreto

Roreto

6,951 km

Double-side SIZING & EDGE BANDING machin

IMACombima II / 440 /A / R3

Call

Condition: excellent (used), Double-side Sizing-Milling & Edge Banding - First (1st) machine in a line

Edges (tape) thickness in rolls (min/max) mm 0,3 / 3

Nedpfxsunrwnj Adwecl

Panels thickness (min/max) mm 8 / 45 (60)

Working width (min/max) mm 236 / 1300

Numerical Control / Software ICOS Open (Windows base)

Adjustable feeding speed (m/min ) 10 - 50

Safety and sound-proof enclosures/cabins

SIZING PART (for each side):

Hogging Units 75.30 (2 x Kw 6,6)

Free space

EDGE-BANDING PART (for each side):

Glueing Unit (Hot Melt + Quick Melt Unit) 04.1570 + 283.201

Pressure zone

Edge coils supporting unit (No. of reels) 6

Rough Trimming unit 08.055 (2 x Kw 1) 0°-30°

Fine Trimming unit 08.055 (2 x Kw 0,66) 0°-30°

Profile Scraping unit 08.515

Free space

Buffing unit 08.617-2 (2 x Kw 0,18)

Nr. 2 Milling grooving units RIGHT: 75.30 (2 x Kw 4,4) 90°-180°

Trust Seal

Dealers certified through Machineseeker

Listing

Roreto

Roreto

6,951 km

Double-side SIZING&EDGE BANDING machine

STEFANI (SCM Group)Evolution C 220

Call

Condition: excellent (used), Double side - Independent Machine (or 1st and/or 2nd in a line)

Edges (band in rolls) thickness (Min/Max) mm 0,4 / 3

Panels thickness (min/max) mm 14 / 60

Working width (min/max) mm mm 260 (ca.) / 3200

Numerical Control /Software MAESTRO PRO EDGE

Adjustable feeding speed (m/min) 10- 40

Safety sound-proof enclosures/cabins + Distance (center-axes) of Disappearing Dogs (mm) 400

SIZING PART (for each side):

Anti-chipping Milling Unit AS (1 x Kw 4)

Hogging Units DTR (2 x Kw 8)

Spraying unit (Anti-sticking liquid) AAR

EDGE-BANDING PART (for each side):

Lamps to heat the workpieces side

Glueing Unit (Hot Melt Glue + Quick Melt system)

Band Pressure zone (N.C. adjustment)

Edge coils support (No 2 reels) motorized

Snipping (end-cutting) unit YU/SP-750 (30 m/min)

Rough Trimming unit RSP

Fine Trimming unit (Multi-profile, by N.C.) RI/S 2P

Nodpfx Adswhi Slewscl

Corner Rounding unit ( Contour Trimming) C1+C2 (4 x Kw 0,35) ED-SYSTEM e Fast-Release

Profile Scraping unit RAS/S

Glue scraping unit RCA/2C

Spraying Unit (for polishing liquid)

Buffing unit SPE

Milling grooving unit U (1 SX + 1 DX) 2 x Kw 5,5

Listing

Roreto

Roreto

6,951 km

Double-side SIZING-EDGE BANDING Machine

IMACombima II 590 / B / R3

Call

Condition: excellent (used), Double side - Independent Machine (or 1st and/or 2nd in a line)

Edges (tape) thickness in rolls (min/max) mm 0,3 / 3 + in stips / lippings (max mm 1)

Panels thickness (min/max) mm 8 / 45 (60)

Working width (min/max) mm 236 (266) / 3300

Numerical Control / Software ICOS Open (Windows base)

Adjustable feeding speed (m/min ) 10 - 50 (Master & Slave)

Safety and sound-proof enclosures/cabins

SIZING PART (for each side):

Anti-chipping Milling Unit 75.186 (1 x Kw 4,4)

Hogging Units (2 x Kw 6,6) Max 35 m/min

Milling unit (Joint Trimmer) 75.186 (1 x Kw 4,4)

EDGE-BANDING PART (for each side):

Glueing Unit (P.U.R. Glue + Quick Melt system) VTG 3-24 + 283.203

Pressure zone + Edge coils supporting unit (No. 24 reels)

Snipping (end-cutting) unit 08.42 / 30 / B (2 x Kw 0,66) 30 m/min (0°-25°)

Rough/Fine Trimming unit 08.055 (2 x Kw 1) 0°-30° (30 m/min)

Multi Function Unit (Profile contour Trimming unit) MFA 08.342 (2 x Kw 0,66) SERVO - 20m/min

Ncedpfoxggzljx Adwol

OPTIONAL: KFA 30

Profile Scraping unit 08.519

Glue scraping unit 08.521

Buffing unit 08.604 (Kw 0,25 x 4)

No. 2 Grooving units 08.190 (1 x Left-hand + 1 x Right-hand) (Kw 4,5 x 2) swivelling 90°/180°/270°

Listing

Roreto

Roreto

6,952 km

COMBI MACHINE (SIZING & EDGE BANDING)

IMACombima /K /II /950 /F /R75 /R1.3

Call

Condition: excellent (used), Double side - Independent Machine (or 1st and/or 2nd in a line)

Edges (band in rolls) thickness (Min/Max) mm 0,4 / 3

Edges thickness in strips/lippings max) mm 1,3

Panels thickness (min/max) mm 10 / 45

Nsdpfx Asfi Tkvedwocl

Working width (min/max) mm 244 / 2300 ca.

Numerical Control /Software ICOS Open

Adjustable feeding speed (m/min ) 8 - 40

Without Transmission bar (Master & Slave system)

Safety and sound-proof enclosures/cabins

Distance (center-axes) of the Disappearing Dogs (mm) 270

SIZING PART (for each side):

Pre-Milling unit 75.30 (Kw 6,6 x 2)

EDGE-BANDING PART (for each side):

Glueing Unit (P.U.R. Glue + Quick Melt system) 04.1570 + 283.205

Edge coils supporting unit (reels N°) 6

Snipping (end-cutting) unit 08.42 (Kw 0,2 x 2) 40 m/min

Fine Trimming unit 08.055 (Kw 0,66 x 2) 0°-30°

Multi Function Unit (Profile contour Trimming unit) MFA 08.342 (Kw 0,66 x 2) max 25 m/min

Corner Rounding unit (Contour Trimming) 08.465 (Kw 0,18 x 4) max 20 m/min

Buffing unit 08.617-2 (Kw 0,18 x 2)

Free space

Listing

Roreto di Cherasco

Roreto di Cherasco

6,952 km

DOUBLE END TENONER

CELASCHI (SCM Group)TSA 200 N

Call

Condition: excellent (used), Independent machine (standing alone) and/or Universal machine (First & Second in a line)

Electronic Programmer

With separate electric and command panel

Safety and sound-proof enclosure

No. 1 Vertical column to support the working units

Min. useful working width (mm) 220

Max. useful working width (mm) 3000

Min. useful working tickness (mm) 6

Max. useful working tickness (mm) 60

Distance between center-axes of the disappearing dogs (mm) 400

Adjustable (min/max) feeding speed (m/min) 4-24

Total installed power Kw 40

No. 3 Working groups (for each machine's side):

1 Jumping Scoring Unit Kw 2,2 / Kw 3,2

Nodpjgz Alxjfx Adwecl

1 Hogging Unit Kw 5,5 / Kw 7,3 (RPM 3000 / 6000)

1 Jumping Milling Unit Kw 4 / Kw 5,8 (RPM 3000 / 6000)

We make it easier for you to find: "sound enclosure"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Sound Enclosure (2,093)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month