Used Welding machines & cutting equipment for sale (2,527)

Sort results

- Lowest price Highest price

- Latest listings Oldest listings

- Shortest distance Farthest distance

- Latest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Latest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Latest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation A to Z

- Designation

- designation Z to A

- Designation

- Model A to Z

- Model

- Model Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest running time

- Runtime

- Relevance

- Relevance

Listing

Šiauliai

Šiauliai

6,015 km

Welding table

KinijaXQL-CSH YAG Pulse Welding Machine

Call

Condition: like new (used), Year of construction: 2020, Functionality: fully functional, XQL-CSH YAG Pulse Welding Machine

XQL-CSH YAG welding machine offers handheld and fixed dual-mode capability with 360° rotation. It transmits welding energy via optical fibers without loss, ensuring fine spot and visually appealing welds without polishing. Optional CCD monitoring enhances clarity, reducing defects. The touchscreen interface makes operation simple and user-friendly.

Product Description

XQL-CSH YAG welding machine features a handheld and fixed dual-mode capability, allowing for a 360°rotation. Welding energy is transmitted through optical fibers with no loss, resulting in fine spots and aesthetically pleasing welding effects without the need for polishing. Optional CCD monitoring ensures clearer welding effect, avoiding the production of defective products. Paired with a touchscreen, the operation is simple and easy to learn. It is suitable for welding and forming various types of metal signs and LED metal letter shells, including fine letters, precision letters, mirror letters, brushed steel letters, and galvanized letters.

Product Advantage

1. High efficiency with no loss of energy transmission, resulting in a fine spot and beautiful welding effect.

2. High quality with a smooth welding seam that requires no subsequent grinding.

3. As low as 2 kW per hour, ensuring cost -effectiveness.

4. A 360-degree flexible movement welder capable of soldering small and complex fonts and logos.

5. Intelligent operation with a touchscreen interface enabling 24-hour uninterrupted work.

……………..

XQL-CSH YAG pulse welding machine

XQL-CSH YAG welding machine is a handheld and stationary dual-mode machine with 360° rotation. It transmits welding energy losslessly through optical fibers, ensuring fine spot and visually appealing welds without polishing. Optional CCD monitoring increases clarity, reduces defects. The touch screen interface makes operation simple and convenient.

Product Description

XQL-CSH YAG welding machine is a handheld and stationary dual-mode welding machine, which can be rotated 360°. The welding energy is transmitted by optical fibers without loss, resulting in a fine spot and aesthetic welding effect that does not require polishing. Optional CCD monitoring ensures a clearer welding effect, thus avoiding the production of poor quality products. Combined with the touch screen, the operation is simple and easy to learn. It is suitable for welding and forming various types of metal signs and LED metal letter bodies, including fine letters, precision letters, mirror letters, brushed steel letters and galvanized letters .

Product Advantages

1. High efficiency without energy transmission loss, resulting in fine spot and beautiful welding effect.

2. High quality with smooth welding seam that does not need to be polished later.

3. Less than 2 kW per hour, ensuring cost-effectiveness.

4. Flexible 360-degree motion welding machine, capable of soldering small and complex fonts and logos.

Djb Hjvr Tb Hodpgkjkl

5. Advanced control with touch screen interface, allowing 24-hour continuous operation.

Listing

Haßloch

Haßloch

6,910 km

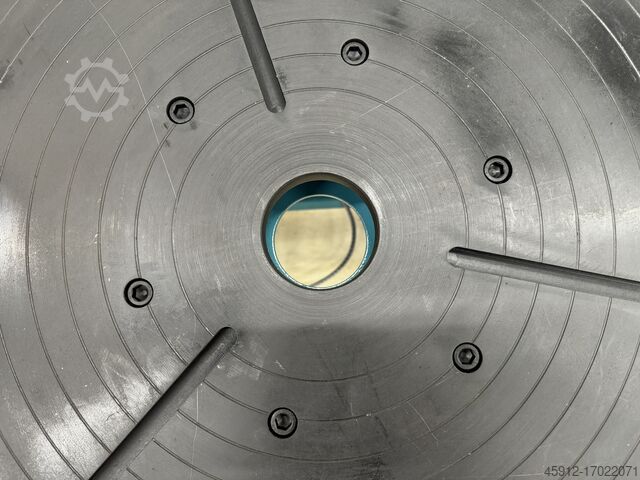

KMT SLV 100 HP S

KMTSLV 100 HP S

Call

Condition: like new (used), Year of construction: 2008, operating hours: 23,412 h, Functionality: fully functional, KMT SV 100 HP S high pressure pump

Sold in overhauled condition.

new pressure intensifier, new control and new HP pump

Oil/air cooling available

Dkobonab Erj Hdpgkol

( Pictures are condition )

Listing

Rödermark

Rödermark

6,869 km

Welding mist filter system

TEKAFILTERCUBE FC 4 H

Call

Condition: used, Year of construction: 2014, machine/vehicle number: 950144105510003, Lg.No. 25044

Welding mist filter system with spark pre-separator + extraction arms

Technical specifications

- Upright design for filtering welding mist + grinding dust

- Welding fume class "W 3"

- Suitable for filtering welding fumes from steels with chromium + nickel content of over 30%

- Exhaust air can be vented into the work area, e.g., for heating, or outside

- TEKA control system

- Air flow rate up to approx. 5000 m³/h

- Max. static pressure up to approx. 3000 pa

Dkjb Hdowgd A Aepgksl

- 4 BIAM filter cartridges

- Pulse Jet cleaning method with separation efficiency > 99%

- Separate control cabinet

- Connection 400 V / 5.5 kW

- Space requirement of filter cube approx. W 850 x H 3150 x D 850 mm

- Weight approx. 380 kg

Listing

Sonneberg

Sonneberg

6,704 km

Welding bevel former Trumpf TKF 104-0

Call

Condition: excellent (used), Beveling Machine

Stock Number: 9283

Manufacturer: Trumpf

Year of Manufacture:

Type: 104-0

Machine Number:

Max. bevel length (infinitely adjustable):

Mild steel at 400 N/mm²: 10 mm

Mild steel at 600 N/mm²: 8 mm

Mild steel at 800 N/mm²: 5 mm

Working Speed: 2 m/min

Rated Power: 2 kW

Stroke Rate at Rated Load: 370 / min

Material Thicknesses Min/Max: 3 / 25 mm

Dksb Hdpowfzzmsgkel

Weight: 16.5 kg

Listing

Hessisch Lichtenau

Hessisch Lichtenau

6,811 km

MIG / MAG pulse inert gas welding machine

REHMRMP 400 Hybrid (REHM-Mega-Puls)

Call

Condition: used, Pulsed MIG Welder REHM Type RMP 400 Hybrid (REHM Mega Pulse)

Manufacturer No. Year of manufacture approx. 1998 (year of manufacture according to manufacturer REHM approx. 1997/1998)

Power 400 amps = 60% duty cycle

320 amps = 100% duty cycle

Deb Hewa Uwdedpgkjkl

Infinitely variable adjustment range

Mains connection 400 volts, 50 Hz, 32 amps plug

- Separate 4-roll wire feeder with connecting hose package (meter)

- Digital display for voltage and current

- Pulse welding device with single and double pulses

- 2-stroke and 4-stroke welding device

- 4-meter Binzel hose package with central connection

- Water-cooled

- Shielding gas pressure regulator

- MIG/MAG pulsed arc welding

- MIG/MAG double-pulse welding

- MIG/MAG welding

Space requirements L x W x H 1150 x 510 x 1350 mm

Weight 200 kg

Good condition

Listing

Almelo

Almelo

7,028 km

Laser cutting machine Fiber-Laser

Fiber Laser CNC laser snijmachine DMA-F3015E

Call

Condition: new, Year of construction: 2025, Functionality: fully functional, Buy your Fiber Laser delivery time 6/8 weeks

buy or financial lease via Danmar Machines BV FIBER LASER

METAL CUTTING MACHINES

Dksb Hdpgewgxq Uekel

Quality, advanced CNC Laser cutting machines for sheet material and tube lengths. Quickly and accurately cut materials in the right shape with a CNC Fiber Laser.

Danmar Machines Fiber Laser machines are produced in Asia. Fast production lead time so fast delivery.

Buy CNC Fiber Laser € 34,500,--*

Working area: 1,500x3,000 mm* ( 4,000x2,000 - 6,000x2,000 )

Laser strength: 1,500* - 3,000 - 4,000 - 6,000W

Metal cutting machines for comparison

Carbon steel (Carbon steel) 1-30mm

Stainless steel (RVS) 1-22mm

Aluminum 1-16mm

Brass 1-16mm

Copper 1-8mm

Contact us for more information, prices and delivery time.

Listing

Kaufungen

Kaufungen

6,818 km

Welding machine

EWMTetrix 421

Call

Condition: good (used), used welding machine

make EWM

type Tetrix 421

Technical data

Adjustment range welding current

5 A - 420 A

Dkebjpmt Ais Hdpgkel

Welding voltage setting range [V]

WIG 10,2 V- 26,8 V

E-Hand 20,2 V- 36,8 V

Duty cycle at 20°C

80%ED 420 A

100%ED 380 A

Duty cycle at 40°C

60%ED 420 A

100%ED 360 A

Load cycle 10 min (60% ED ∧ 6 min welding, 4min pause)

Open circuit voltage 95 V 92 V 79 V

Mains voltage (tolerances) 3 x 400 V (-25 % to +20 %)

3 x 415 V (-25 % to +15 %)

Frequency 50/60 Hz

Mains fuse

(fuse, slow blow)

3 x 35 A 3 x 35 A

max. tank capacity 12 l

Workpiece cable 70 mm2

95 mm2

Dimensions L/W/H [mm] 950 1080

weight 168,5 Kg 176 Kg

Listing

Gorzów Wielkopolski

Gorzów Wielkopolski

6,448 km

Welding fume aspiration OS 3008

Viber-systemOS 3008

Call

Condition: new, Year of construction: 2024, The OS 3008 welding extractor is ideal for extracting smoke and fumes generated during welding, polishing, cutting or grinding rare precious metals.

It can purify large amounts of harmful metal particles suspended in the air. This machine is characterized by high purification efficiency, low noise emission and takes up a relatively small area. It is adapted for extraction during arc welding, carbon dioxide, MIG/MAG method, gouge arc, welding in the gas environment.

Suction power: 3000 m^3/h

These extractors are equipped with high-performance filter inserts, distinguished from conventional filters by the presence of a PTFE (Polytetrafluoroethylene) membrane layer.

In conventional filters, the length of the fibers of traditional filter materials such as cotton, satin, paper and other cellulose fibers is from 5 to 60 µm. Soot particles contained in the extracted smoke can remain inside the filter, blocking the filter element. When the blockage becomes too large, the ash cannot be effectively removed from the filter element, the air resistance increases and the gas flow decreases. As the filter becomes more contaminated, the filtering efficiency drops dramatically.

Our filter contains a PTFE membrane layer, the fine structure of which blocks microscopic dust particles. These particles block the dust layer on the surface of the filter material. Most of the dust particles are blocked on the outer surface of the filter, not penetrating the filter interior. Over time, the particles can be removed from the filter by the flow of purified, compressed air.

Air volume (m^3/h) 3000

Pressure (Pa) 2000

Filter efficiency (%) 99.9

Power (kW) 3

Filter area 30

Filter size 700 x 750 x 1700 mm

Voltage (V) 380

Weight (kg) 90

Dkjb Hdpjtu H N Hjgkel

Listing

Portet-sur-Garonne

Portet-sur-Garonne

7,475 km

Welding robot

YaskawaAR2010

Call

Condition: excellent (used), Year of construction: 2020, operating hours: 4,181 h, Functionality: fully functional, machine/vehicle number: SB4568, ROBOTICS:

1 MAG welding robot, 6 axes, model AR2010, equipped with its YRC1000 control cabinet.

1 robot control panel with color touchscreen.

Djbjwhl N He Hdpgkokl

1 R2L type positioner with five controlled axes. The load capacity is 250 kg per workstation. The usable volume is represented by a cylinder with a 1600 mm diameter.

5-axis control system.

1 relocation system via 200 Volt wire.

1 DeviceNet welding control card.

ENCLOSURE & SAFETY:

1 enclosure made of sheet metal panels.

1 operator panel.

1 operator loading station secured by a light curtain, a pre-reset button, and a two-color signal light.

MAG WELDING EQUIPMENT:

1 MIG/MAG welding power source, brand FRONIUS, model TPSi 400 CMT with:

- WF25i-R 4-roller wire feeder

- CU-1400i water cooler

- robot control interface

- WF60i-WR water-cooled torch

- wire block

1 mechanical torch cleaning system, MOTOMAN Type TCS-C

EXTRACTION:

KEMPER Filtration system included

Listing

Friesenheim

Friesenheim

6,938 km

Plasma cutting machine

ErfiPS990

Call

Condition: new, Plasma cutter Erfi PS990

Manufacturer: Erfi

Type: PS990

Plasma cutting machine ERFI PS990 - powerful, single-stage plasma cutter. Up to 20mm clean cut in steel, up to 25mm separating cut. Contact-free ignition by HF-ignition also on paint and rust by pilot arc.

Includes 6m torch, standard filter and integrated pressure reducer with pressure gauge.

The ERFI devices are produced with the utmost care in Germany - that is why ERFI always gives a guarantee of 3 years - without restriction.

Technical data:

Mains voltage 3x400V

Frequency 50Hz

Fuse protection 32A slow-blow

Djb Hjwbqn Uedpgkokl

Cutting current 60A level 1/ 90A level 2 Air pressure 6-10bar

Weight 105kg

Available immediately. For collection by the customer. Forklift available. Shipping also possible

Subject to errors and prior sale

Listing

Hessisch Lichtenau

Hessisch Lichtenau

6,811 km

Clinch unit TOX - Pneumatic-Hydro Toxpress,; Hydro-Pneumatic Press

KRAFT PAKET - TOX PressotechnikCRS 03.58

Call

Condition: used, TOX Clinching Unit - Pneumatic Hydro Tox Press

TOX Pressotechnik POWER PACKAGE Hydro-Pneumatic Press

Type CRS 03.58 - No. 207588.3

Year of manufacture approx. 2005

Pressure capacity: max. 57 kN = 5.7 tons

Stroke: approx. 50 mm

Power stroke: approx. 10 mm

Throat: 60 mm

- Pneumatic stroke release

- Built-in clinching tool

- Pneumatic valve for control

- Without electrical control

- For creating a positive connection between two sheets without piercing or heating the sheets

Weight: approx. 120 kg

Very good condition,

Comes from a production facility, but this was rarely used

Djb Hdpgowa Uuijkokl

Several TOX Clinch units available

Price per clinching unit

Listing

Rohrbach

Rohrbach

6,488 km

Water Jet Cutting Machine

STM Stein-Moser GmbHWS 4020 Wanne 4.2

Call

Condition: used, Year of construction: 2010, x-travel 4002 mm

y-travel 2002 mm

z-travel 200 mm

table dimension - longitudinal 4200 mm

table dimension - cross 2130 mm

rapid traverse 20 m/min

total power requirement 9 kW

weight of the machine ca. 8 t

Dksb Hdpgswd Nkaskol

dimensions of the machine ca. 5,2 x 3 m

The WaterJet STM, built in 2010 by the renowned Austrian company Stein-Moser GmbH, is used for precise waterjet cutting of details with a maximum thickness of 200 mm

Operating pressure water jet min. 500 - max. 4000 bar

Equipment of the STM waterjet cutter

- Control panel with CNC control

- High-pressure pump: BHDT ECOTRON

- Collision collision protection

Listing

Kaufungen

Kaufungen

6,818 km

TIG welder

RehmTranstig 330 DC

Call

Condition: good (used), Year of construction: 2015, 1 used TIG welder

make Rehm

type Transtig 330 DC

serial number 148392

Technical data

Dkjb Hdpjn I T Ulsgkjl

connection cable 400V/32A CEE plug

Adjustment range TIG 6 - 330 A

Adjustment range electrode 6 - 330 A

Duty cycle TIG 55 %

at I max (10min.) electrode 25%

Welding current TIG 265 A

at 100 % ED electrode 265 A

Power consumption TIG 11.9 kVA

Open circuit voltage 60 V

Torch cooling water

Protection class IP 23

Weight 92 / 88 kg

Dimensions (LxWxH in mm) 850 x 420 x 860

Listing

Siedlce

Siedlce

5,967 km

Industrial fume and dust extraction

CORMAKODL6K

Call

Condition: new, Year of construction: 2025, The CORMAK ODL6K extraction and filtration system is a modern solution that provides safe working conditions for operators and effective protection of laser system components against contamination and damage. Filtration at a level of 99.9% removes harmful particles and fumes, guaranteeing clean air in the workplace.

The ODL6K is distinguished by an automatic filter cleaning system, an efficient fan, and a compact, solid design that allows for easy integration with various cutting systems. An additional advantage is the ergonomic waste drawer, which allows for quick and convenient emptying of collected waste.

This is a comprehensive solution that increases safety, improves work efficiency and extends the service life of laser systems.

The ODL6K combines automatic filter cleaning with compressed air, an efficient fan generating high negative pressure and filtration at a level of 99.9% for particles of 0.3 μm thanks to the use of appropriate filters.

The system is equipped with an ergonomic dirt drawer, which allows for quick and convenient removal of accumulated dust without the need for disassembly. Additionally, thanks to the modular design, it is possible to mount extraction nozzles on both the left and right side of the device, which allows for flexible adjustment of the installation to the layout of the production hall.

ODL6K is a compact, efficient and reliable solution for any laser cutting system - increasing safety, comfort and work efficiency.

The main functions of the exhaust gas extraction and filtration system in the laser processing process are:

Removal and neutralization of laser smoke.

Ensuring work safety at the laser station and in its immediate vicinity.

Extending the service life of laser systems by keeping them clean and protecting important components from contamination.

The most important advantages of the CORMAK ODL6K extraction system:

The extraction system has automatic filter cleaning using compressed air. Under the influence of pressure, the filter is "shaken off", which effectively cleans the filter cartridge and thus extends its service life. Thanks to this, the system maintains its efficiency for a longer period of time.

Dkebowcd I Ro Hdpgkjl

The filter element used in the system is imported and made of high-quality material. The Nano-type fireproof filter has high filtration efficiency, retaining particles of 0.3 μm in more than 99.9%.

The large dust collection drawer allows convenient dust collection and cleaning, which makes the system easy to maintain.

The motors used in the system are equipped with overload protection, thus ensuring a high level of protection and trouble-free operation.

The specially developed high-performance fan wheel generates a large negative pressure, which allows effective removal of laser exhaust gas and ensures high airflow efficiency.

The total purification efficiency of the system is 0.3 μm, and the efficiency is more than 99.9%, which shows the high efficiency of the exhaust in removing harmful particles from the air. In addition, it is characterized by a compact structure, which makes it easy to operate and maintain.

Technical parameters

Number of filter cartridges 6

Air flow 6000 m³/h

Air pressure 3000 Pa

Filtration efficiency 99.99%

Filter size 350x660 mm

Fan power 7.5 kW

Inlet diameter 300 mm

Weight 590 kg

Dimensions (L x W x H) 1150 x 1950 x 2250 mm

Listing

Klein-Winternheim

Klein-Winternheim

6,913 km

Pen Feeder 1.2 - 1.6 mm

TBIPen Feeder

Call

Condition: excellent (used), The TBi PenFeeder is a feed drive for TIG and plasma welding. It is a machine-independent addition to any TIG welding station and helps to make manual TIG welding faster and more efficient. It thus offers practical time, efficiency and cost advantages for industrial production.

Dob Hdpgog Uwb Ujkekl

Listing

Friesenheim

Friesenheim

6,938 km

Welding machine

RehmSYNERGIC.PRO² 311-4

Call

Condition: new, As a machine dealer in Offenburg, we offer premium welding machines from Rehm. Many machines are immediately available from stock. We are also happy to advise you with regard to individual wishes and requirements. Give us a call.

Technical data:

Setting range [A]: 35-300

Duty cycle (ED) at I-max. [%]: 40

Welding current at 100 % duty cycle [A]: 210

Open circuit voltage [V]: 17-40

Switching stages: 12

Wire feed [Ø mm] : 1.0

Fuse protection (slow) [A]: 32

Torch cooling: Gas

Protection class: IP 21

Mains voltage [V]: 3 x 400

Dkeb Hdowbpr Sopgkol

Control socket [pol.]: without

Welding cable socket [mm]: 13

Weight [kg] : approx. 78

Dimensions L x W x H [mm]: 800 x 330 x 620

Possible accessories:

Hand burner

earth cable

Pressure reducer

Coil adapter

Welding rod

Available immediately. For collection by the customer. Forklift available. Shipping is also possible.

Listing

Enschede

Enschede

7,014 km

Welding table

AYEL-TECHHB-6

Call

Condition: new, rotary table diameter: 650 mm, - Horizontal load capacity 600 kg

- Vertical load capacity 300 kg

- Table size 650 mm

- Passage 80 mm

- Electrically tiltable

- Wired remote control

- Digital display

Dsb Hdpgsuitd Dekekl

- Documentation

- 400V

Listing

Japan

Japan

5,966 km

Dual-purpose machine

BodorA3T

Call

Year of construction: 2022, Condition: new, Entry-level fiber laser metal sheet&tube cutting machine

One machine with two uses. AT series cuts both metal sheets and metal tubes.

The modular cutting machine table with stiffeners saves time for disassambly and improves convenience and rigidity.

Cutting machine clamping becomes convenient, easy and fast, with 3 seconds at the soonest to clamp and high repeat precision

Fast air cutting efficiency increases by 37% when cutting carbon steel.

Fiber laser heads are able to detect jutting obstacles to effectively reduce the damage rate and save the maintenance cost of a laser cutter.

Angle steel and channel steel cutting are standard with no need fior additional installation.

Dkob Hdpshv U Ucogkjl

Condition: New

Laser Type: Fiber Laser

Laser Power: 1000W, 1500W, 2000W, 3000W

Cutting Area: 3048*1524mm

Cutting Speed: 0-100m/min

Positioning accuracy: ±0.03mm

Repositioning accuracy: ±0.02mm

Graphic Format Supported: AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

CNC or Not: Yes

Cooling Mode: WATER COOLING

Listing

Ennepetal

Ennepetal

6,975 km

Welding Table

GERD WOLFF2000 x 3000 x 200

Call

Condition: new, Year of construction: 2025, table length 3000 mm

table width 2000 mm

table height 200 mm

weight 1700 kg

Manufacturer: GERD WOLFF

Technical Details:

• Length 2000 mm

• Width 3000 mm

• Height 200 mm

• Weight 1700 kg

• Hole diameter 28 mm

• Hole spacing 100 mm

• Plate thickness: 25mm

Advantages and Features:

• 3-day gas nitriding process

• Increased corrosion resistance

• Weld spatter adhesion protection

• Maximum load capacity

• Enhanced fatigue strength

• Improved vibration resistance

• Fine scale engraving

• Reinforcement with welded seams and ribs on the underside

• Optimal working height of 820-865 mm

• 8 height-adjustable support legs

• Available with a matching accessory set (optional)

• Plate thickness: 25mm

Our welding tables are manufactured using HT 300 cast iron and are nitrided as

a whole after mechanical processing. Furthermore, they feature precise fine

scale engraving using laser technology.

To ensure adequate stability, our welding tables are reinforced with welded

seams and ribs on the underside (see illustrations). Additionally, they undergo

a 3-day gas nitriding process, enhancing their corrosion resistance, fatigue

strength, and vibration resistance, among other factors.

Dkeb Hdjuia Ntjpgkol

All our tables come with adjustable legs. The minimum height adjustment range

is 620 mm, while the maximum is 665 mm, allowing for a variable working height

of 820 to 865 mm.

Additional available dimensions:

• 1000 x 1000 x 200

• 2000 x 1000 x 200

• 1200 x 1200 x 200

• 1500 x 1000 x 200

• 1500 x 1500 x 200

• 1500 x 2000 x 200

• 2000 x 3000 x 200

• 3000 x 1500 x 200

• 3000 x 2000 x 200

• 4000 x 2000 x 200

• 2400 x 1200 x 200

Please note that the images are not to scale and are for illustrative purposes

only. Our welding tables are produced for our distribution brand "GERD WOLFF

Maschinenfabrik" by a reputable manufacturer.

3D Welding Table - 3D Clamping Fixtures - 3D Precision Welding Table

Listing

Siedlce

Siedlce

5,967 km

Industrial fume and dust extraction

CORMAKODL4K

Call

Condition: new, Year of construction: 2025, The CORMAK ODL4K extraction and filtration system is a modern solution that ensures safe working conditions for operators and effective protection of laser system components against contamination and damage. Filtration at a level of 99.9% removes harmful particles and fumes, guaranteeing clean air in the workplace.

ODL4K stands out with an automatic filter cleaning system, an efficient fan, and a compact, solid design that allows for easy integration with various cutting systems. An additional advantage is the ergonomic waste drawer, which allows for quick and convenient emptying of collected waste.

The modern ODL4K extraction system ensures effective filtration of contaminants and protection of the most important components of the laser system.

ODL4K combines automatic filter cleaning with compressed air, an efficient fan generating high negative pressure and filtration at a level of 99.9% for particles of 0.3 μm thanks to the use of appropriate filters.

The system is equipped with an ergonomic dirt drawer, which allows for quick and convenient removal of accumulated dust without the need for disassembly. Additionally, thanks to the modular design, it is possible to mount extraction nozzles on both the left and right side of the device, which allows for flexible adjustment of the installation to the layout of the production hall.

ODL4K is a compact, efficient and reliable solution for any laser cutting system - increasing safety, comfort and work efficiency.

The main functions of the exhaust gas extraction and filtration system in the laser processing process are:

Removal and neutralization of laser smoke.

Dkeb Hdpgowcdrvekel

Ensuring work safety at the laser station and in its immediate vicinity.

Extending the service life of laser systems by keeping them clean and protecting important components from contamination.

The most important advantages of the CORMAK ODL4K extraction system:

The extraction system has automatic filter cleaning using compressed air. Under the influence of pressure, the filter is "shaken off", which effectively cleans the filter cartridge and thus extends its service life. Thanks to this, the system maintains its efficiency for a longer period of time.

The filter element used in the system is imported and made of high-quality material. The Nano-type fire-resistant filter has high filtration efficiency, retaining particles of 0.3 μm in more than 99.9%.

The large dust collection drawer allows convenient collection and cleaning of dust, which makes the system easy to maintain.

The motors used in the system are equipped with overload protection, thus ensuring a high level of protection and trouble-free operation.

The specially developed high-performance fan wheel generates a large negative pressure, which allows effective removal of laser exhaust gas and ensures high airflow efficiency.

The total purification efficiency of the system is 0.3 μm, and the efficiency is more than 99.9%, which shows the high efficiency of the exhaust in removing harmful particles from the air. In addition, it is characterized by a compact structure, which makes it easy to operate and maintain.

Technical parameters:

Number of filter cartridges 4

Air flow 4000 m³/h

Air pressure 3000 Pa

Filtration efficiency 99.99%

Filter size 350x660 mm

Fan power 5.5 kW

Inlet diameter 250 mm

Weight 420 kg

Dimensions (L x W x H) 1050 x 1400 x 2250 mm

Listing

Friesenheim

Friesenheim

6,938 km

Welding machine

RehmINVERTIG.PRO digital 280 AC/DC

Call

Condition: new, As a machine dealer in Offenburg, we offer premium welding machines from Rehm. Many machines are immediately available from stock. We are also happy to advise you with regard to individual wishes and requirements. Give us a call.

Technical data

Model: 280 AC/DC

Setting range

TIG [A]: 3-280

Electrode (BOOSTER) [A]: 3-280

Duty cycle (ED) at Imax. (10 min.)

TIG [%]: 100

Electrode (booster) [%]: 60

Welding current at 100 % duty cycle at 40°C

TIG [A]: 280

Electrode (booster) [A]: 260

Fuse protection (slow) [A]: 16

Torch cooling: Water

Protection class: IP 23

Power factor [cos phi]: 0.96

Power consumption at Imax. [kVA]: 11.9

Mains voltage [V]: 3 x 400

Dkjbjwbpr Ej Hdpgkel

Mains frequency [HZ]: 50

Control socket [pol.]: 12

Welding cable socket [mm]: 13

Weight [kg]: 27

Dimension [mm]: 520 x 360 x 460

Possible accessories:

Hand burner

earth cable

Pressure reducer

Available immediately. For collection by the customer. Forklift available. Shipping is also possible.

Trust Seal

Dealers certified through Machineseeker

Listing

Germany

Germany

6,975 km

Welding Table

GERD WOLFF3000 x 1500 x 200

Call

Condition: new, Year of construction: 2025, table length 3000 mm

table width 1500 mm

table height 200 mm

weight 1500 kg

Manufacturer: GERD WOLFF

Technical Details:

• Length 3000 mm

• Width 1500 mm

• Height 200 mm

• Weight 1500 kg

• Hole diameter 28 mm

• Hole spacing 100 mm

• Plate thickness: 25mm

Advantages and Features:

• 3-day gas nitriding process

• Increased corrosion resistance

• Weld spatter adhesion protection

• Maximum load capacity

• Enhanced fatigue strength

• Improved vibration resistance

• Fine scale engraving

• Reinforcement with welded seams and ribs on the underside

• Optimal working height of 820-865 mm

• 8 height-adjustable support legs

• Available with a matching accessory set (optional)

Dkjb Houia Nmedpgkjl

Our welding tables are manufactured using HT 300 cast iron and are nitrided as

a whole after mechanical processing. Furthermore, they feature precise fine

scale engraving using laser technology.

To ensure adequate stability, our welding tables are reinforced with welded

seams and ribs on the underside (see illustrations). Additionally, they undergo

a 3-day gas nitriding process, enhancing their corrosion resistance, fatigue

strength, and vibration resistance, among other factors.

All our tables come with adjustable legs. The minimum height adjustment range

is 620 mm, while the maximum is 665 mm, allowing for a variable working height

of 820 to 865 mm.

Additional available dimensions:

• 1000 x 1000 x 200

• 2000 x 1000 x 200

• 1200 x 1200 x 200

• 1500 x 1000 x 200

• 1500 x 1500 x 200

• 1500 x 2000 x 200

• 2000 x 3000 x 200

• 3000 x 1500 x 200

• 3000 x 2000 x 200

• 4000 x 2000 x 200

Please note that the images are not to scale and are for illustrative purposes

only. Our welding tables are produced for our distribution brand "GERD WOLFF

Maschinenfabrik" by a reputable manufacturer.

3D Welding Table - 3D Clamping Fixtures - 3D Precision Welding Table

Listing

Friesenheim

Friesenheim

6,938 km

Welding machine

RehmTiger 230 AC/DC ULTRA DIGITAL SET

Call

Condition: new, Mains voltage / mains connection 230 V

Fuse protection 16 A

Frequency 50/60 kHz

Power factor 0.99 Cosphi

Duty cycle at Imax. 40°C 35 %

Setting range TIG 4-230 A

Power consumption 5.8 kVA

Weight 7.9 kg

Mains voltage / mains connection 230 V

Dkjb Hjwbprxedpgksl

Fuse protection 16 A

Setting range TIG 4-230 A

Digital operation of the device

Scope of delivery:

- Tiger 230 AC/DC Ultra digital NEW

- Abicor Binzel Abitig 26 4m U/D hose package NEW

- Pressure reducer NEW

- Dimension cable 5m

Listing

Friesenheim

Friesenheim

6,938 km

MIG MAG welder

REHMFOCUS.ARC P

Call

Condition: new, As a REHM specialist dealer, we now have the opportunity for customers in Offenburg and the surrounding area to receive up to 40% subsidy from the state when purchasing a new MIG/MAG PULS welding machine.

Our welding expert and REHM specialist will be happy to advise you and looks forward to your inquiries.

REHM MIG/MAG welding machine FOCUS.ARC P REDUCES CO2 AND BRINGS MONEY FROM THE STATE

WHO SUPPORTS?

The Federal Office of Economics and Export Control (BAFA) supports investment measures to optimize the energy efficiency of systems and processes.

WHAT IS SUPPORTED?

Investments that demonstrably lead to energy savings and thus to a reduction in CO2 emissions can be subsidized.

For example, if you want to replace step-switched welding machines with high energy consumption with efficient REHM welding technology, you can

take advantage of the Module 4 subsidy. The costs for drawing up the energy-saving concept and implementation support from an external energy consultant are also eligible for funding. The amortization period for the entire measure must be more than 2 years.

HOW MUCH FUNDING IS AVAILABLE?

Up to:

- 40 % of the costs

- 900 € per t CO2

- 10 million €

BAFA supports large companies with up to 30% (maximum €500 per tonne of

ton of CO2 saved) and small and medium-sized companies with up to 40% (maximum €900 per ton of

ton of CO2 saved) of the eligible costs. The maximum funding amounts to

10 million per investment project.

WHO IS ELIGIBLE FOR FUNDING?

Private and municipal companies with a permanent establishment or branch in Germany are eligible to apply. The planned measures must be carried out on the territory of the Federal Republic of Germany. A BAFA-approved energy consultant must be commissioned to draw up the obligatory energy-saving concept.

HOW DO YOU APPLY FOR FUNDING?

01. list: Make a list of all appliances that are to be replaced and all appliances that are to be purchased.

02. check: We take the necessary data from you and check your funding amount provisionally. At the same time, we prepare a quotation for the new welding equipment.

03. energy consultant: We prepare all the data for you and pass it on to an energy consultant who works with us. This saves you time and money.

04. application: After checking the data, the energy consultant submits the application for funding on your behalf.

05. processing time: If it is urgent, we can speed up the processing of the application for you.

for you. This reduces the processing time to

approx. 10 to 15 days.

The following MIG/MAG PULS welding machines from REHM are eligible for BAFA funding:

Without wire feed case:

FOCUS.ARC P 250 0.8/1.0mm

FOCUS.ARC P 250 W 0.8/1.0mm

FOCUS.ARC P 300 1.0/1.2mm

FOCUS.ARC P 300 W 1.0/1.2mm

FOCUS.ARC P 350 1.0/1.2mm

FOCUS.ARC P 350 W 1.0/1.2mm

FOCUS.ARC P 400 1.0/1.2mm

FOCUS.ARC P 400 W 1.0/1.2mm

FOCUS.ARC P 450 1.0/1.2mm

FOCUS.ARC P 450 W 1.0/1.2mm

With wire feed case:

FOCUS.ARC P 250 S 0.8/1.0mm

FOCUS.ARC P 250 WS 0.8/1.0mm

FOCUS.ARC P 300 S 1.0/1.2mm

FOCUS.ARC P 300 WS 1.0/1.2mm

Dkob Hdpjwbprlsgksl

FOCUS.ARC P 350 S 1.0/1.2mm

FOCUS.ARC P 350 WS 1.0/1.2mm

FOCUS.ARC P 400 S 1.0/1.2mm

FOCUS.ARC P 400 WS 1.0/1.2mm

FOCUS.ARC P 450 S 1.0/1.2mm

FOCUS.ARC P 450 WS 1.0/1.2mm

Our welding expert and REHM specialist will be happy to advise you and looks forward to your inquiries.

Listing

Friesenheim

Friesenheim

6,938 km

MIG MAG welder

REHMFOCUS.ARC 300 = 270A bei ED100%

Call

Condition: new, As a machine dealer in Offenburg, we also have welding machines from Rehm in our program. You can get an overview of the machines on our website. If you have any questions, just give us a call.

MIG MAG welding machine REHM FOCUS.ARC 300

Manufacturer: REHM

Type: FOCUS.ARC 300

Scope of delivery:

Dkjb Hdpgswbprfekel

- Hose package Abicor Binzel 401 4m

- Dimension cable 50mm 5m

- Pressure reducer

- Basket coil adapter

Available immediately. For collection by the customer. Forklift available. Shipping also possible

Errors, changes and prior sale reserved.

Not the right machine? Then visit our website.

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Welding machines & cutting equipment (2,527)

Search Machineseeker now with more than 2,00,000 used machines:This may be of interest to you