Used Cnc Turning Center for sale (21,218)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Dieburg

Dieburg

6,868 km

CNC turning and milling center

MTRENTMTCUT T20MC

Call

Condition: excellent (used), Year of construction: 2011, CNC Turning-Milling Center

MTCUT T20MC

Year of manufacture: 2011

Driven tools available

Accessories included

Technical data:

Working area

• Max. swing diameter: Ø 470 mm (18.5”)

• Max. machining diameter: Ø 280 mm (11.02”)

• Max. machining length: 508 mm (20”)

• Bed slide and inclination angle: 45°

Bed

• Max. longitudinal travel (Z-axis): 520 mm (20.47”)

• Z-axis servo motor: 1.4 kW (1.8 HP)

• Z-axis rapid traverse: 30 m/min (1181”/min)

• Max. cross travel (X-axis): 176 mm (6.93”)

• X-axis servo motor: 1.4 kW (1.8 HP)

• X-axis rapid traverse: 30 m/min (1181”/min)

Spindle

• Main spindle bore / draw tube diameter: Ø 62 mm (Ø 2.44”) / Ø 52 mm (Ø 2.04”)

• Spindle nose: ASA A2-6

• Taper angle of the bore in 8" spindle: 1/20

Dedpfx Aoxtnhaeg Rjcb

• AC main spindle motor: FANUC 7.5/11 kW (10 HP / 15 HP)

• Speed (8" main spindle): Standard 4500 rpm

Tool turret

• Type: Hydraulic clamping device

• Boring bar diameter / position: Ø 32 mm

• Turning tool cross-section / position: □ 20 mm × 20 mm / □ 25 mm × 25 mm

Tailstock

• Quill diameter: Ø 75 mm (2.95”)

• Stroke: 425 mm (16.73”)

• Quill type: Fixed

• Quill taper: MT No. 4

• Quill travel: 100 mm (3.94”)

Listing

Schijndel

Schijndel

7,107 km

CNC turning and milling center

DMG MORICTX alpha 500 V5

Call

Condition: excellent (used), Year of construction: 2015, functionality: fully functional, turning length: 500 mm, turning diameter over cross slide: 290 mm, turning diameter: 240 mm, spindle speed (max.): 5,500 rpm, spindle bore: 73 mm, travel distance X-axis: 210 mm, travel distance Y-axis: 80 mm, travel distance Z-axis: 525 mm, rapid traverse X-axis: 30 m/min, rapid traverse Y-axis: 23 m/min, rapid traverse Z-axis: 30 m/min, type of input current: three-phase, torque: 192 Nm, workpiece weight (max.): 30 kg, total height: 1,829 mm, total length: 4,066 mm, total width: 2,583 mm, collet bore: 73 mm, bar diameter (max.): 73 mm, swing diameter over cross slide: 290 mm, spindle nose: FL 140h5, overall weight: 4,300 kg, Equipment: documentation/manual, rotational speed infinitely variable, This DMG MORI CTX alpha 500 V5 from 2015 is in very neat condition and has 7,040 spindle hours on the clock. In 2020, the machine was fitted with a BMO automation, type Iridium Ir 25F, but has seen little production since then.

PLEASE NOTE! The 2 panels with laser/motion sensor are not shown in the photo but are, of course, included.

This CTX alpha 500 is equipped with:

- BMO Iridium Ir25F automation (2020).

- LNS Quick Load Servo III bar feeder (2016).

- Schunk Rota THW plus powered chuck with quick-change jaw system.

- Various top jaws.

- DMG CELOS software.

- Chip conveyor.

- Workpiece catcher/ejector.

- Tool measurement arm.

- Foot pedal for chuck clamping/unclamping.

Dcjdjx Rqwhjpfx Ag Rob

- Miscellaneous tooling (driven & static).

- Original DMG documentation.

Listing

Uttendorf

Uttendorf

6,549 km

CNC turning and milling center

MazakINTEGREX i 250H S

Call

Condition: excellent (used), Year of construction: 2021, Turning length: 1,500 mm

Max. turning diameter: 670 mm

Max. main spindle speed: 5,000 rpm

Max. sub spindle speed: 5,000 rpm

Milling unit tool holder: CAPTO C6

Dsdpfx Asx Nm Uaeg Rjcb

Includes HAINBUCH chuck with quick-change system

Includes bar feeder

Includes KNOLL chip conveyor / band filter

Includes various tools

Includes complete documentation

Listing

Dreieich

Dreieich

6,879 km

CNC Turning- and Milling Center

HWACHEONHi-Tech 200 B I

Call

Condition: used, Year of construction: 2008, turning diameter 210 / 350 mm

turning length 400 mm

control Fanuc 0i-TC

swing diameter 500 mm

travel -x axis 195 mm

travel -z axis 430 mm

spindle speed: 3500 1/min

spindle bore 75 mm

bar diameter 51 mm

C-Axis 0,001 °

turret head 12 Pos.

taper in tailstock-quill MK 4

tailstock travel 100 mm

diameter of quill 80 mm

rapid traverse X-axis 30 m/min

rapid traverse Z-axis 30 m/min

drive capacity - spindle motor 11 / 15 kW

voltage 400 V

total power requirement 30 kVA

weight of the machine ca. 4,2 t

dimensions of the machine ca. 2,70 x 1,90 x 2,10 m

chip conveyor 2,80 x 0,60 x 1,30 m

Transformer 0,60 x 0,45 x 0,55 m

- Serial-No.: M015356K2F

- Machine ON: 14.494 h

- control: FANUC Oi-TC

- Machine with C-axis and

turret for life tools

(1x radial + 1x axial in the accessories)

Dcodpfsttckmox Ag Rob

- Tool meeasuring arm

- Parts collecting tray

- Collet chuck

- 3-jaw chuck Samchully Ø 250 mm

- Open center clamping cylinder

- Automatic sliding door

- chip conveyor

Listing

Tipton

Tipton

7,615 km

CNC turning and milling center

JOHNFORDVTC 880

Call

Condition: ready for operation (used), Year of construction: 2001, JOHNFORD VTC 880 TWIN PALLET CNC VERTICAL LATHE

MAKE JOHNFORD, MADE IN TAIWAN

MODEL VTC 880 + APC + ATC

YEAR 2001

CONTROL FANUC 18 T

Djdpeukuprefx Ag Rjcb

MAX SWING DIA 1,000 mm

MAX CUTTING DIA 900.0 mm

STANDARD CUTTING DIA 800.0 mm

MAX CUTTING HEIGHT 800.0 mm

TRAVERSES X AXIS 50.0 mm to 810.0 mm

Z AXIS 880.0 mm

SPINDLE SPEEDS 10 to 800 RPM

SPINDLE BEARING DIA 330.0 mm

SPINDLE NOSE A2 - 11

SPINDLE MOTOR 18.5 / 22 kW

TURRET TYPE AUTOMATIC TOOL CHANGER

NO OF TYPES 2 X 12 ATC

TOOLS SHANK SIZE BT 50 AND CAPTO

PLUS FULL C AXIS

MILLING

TAPPING

X, Z, C, A AND B AXES

HIGH PRESSURE COOLANT

PAPER COOLANT FILTRATION

SWARF CONVEYOR

FULLY OPERATIONAL

FULL SET OF MANUALS

GOOD RANGE OF TOOLING

Listing

Germany

Germany

7,039 km

CNC Turning- and Milling Center

TRAUBTNA 480 L

Call

Condition: used, Year of construction: 1990, Technical details:

Dodjw I R Ndepfx Ag Rocb

turning diameter: 445 mm

turning length: 2000 mm

turning diameter over bed slide: 660

spindle bore: 65 mm

spindle speeds:: 16 - 3150 U/min.

rapid motion - x-axis: 10 mm/min

rapid traverse Z-axis: 15 m/min

total power requirement: 34 kW

weight of the machine ca.: 7,5 t

dimensions of the machine ca.: 6 x 2,5 x 2,2 m

with CNC Control TX 8 D

C-axis driven tooling

14 station turret head

3 jaw chuck dia. 315 mm

tailstock, steady as NC-axis

diverse driven toolholders

diverse turning toolholders

chip conveyor and coolant attachment

*

Listing

Dieburg

Dieburg

6,868 km

CNC turning and milling center

MAZAKSQT 200 MS

Call

Condition: excellent (used), Year of construction: 1999, CNC Lathe

MAZAK SQT 200 MS

Year of manufacture: 1999

Including indicated tools and sub-spindle

Control: Mazatrol PC Fusion CNC 640T

Technical specifications:

Max. swing diameter: 525 mm

Max. swing diameter over saddle: 350 mm

Max. turning diameter: 300 mm

Bar work up to max. diameter: 51 mm

Main spindle:

Dsdex Hgl Hjpfx Ag Recb

Speed range: 35 – 4,000 rpm

Main drive power: 15 kW

Max. torque: 350 Nm

Spindle nose: A2 – 6 inch

Spindle bore: 61 mm

Spindle positioning C-axis: 0° - 360°/0.001°

Second spindle:

Speed range: 35 – 5,000 rpm

Drive power: 7.5 kW

Max. torque: 57 Nm

Indexing: 72 positions/5°

Tool turret:

Number of tool stations: 12

(freely configurable with stationary and driven tools)

Turret indexing time – 1st station: approx. 0.2 s

Driven tools:

Drive power: 3.7 kW

Max. torque: 35 Nm

Speed range: 25 – 4,500 rpm

Travel:

Turret travel:

X-axis: 190 mm

Z-axis: 575 mm

B-axis: 585 mm

Rapid traverse:

X-axis: 30 m/min

Z-axis: 30 m/min

B-axis: 18 m/min

Feed range:

X/Z-axis: 0 – 5,000 mm/min

C-axis: 1 – 2,000°/min

Listing

Germany

Germany

6,878 km

CNC Turning- and Milling Center

PFIFFNER-MANURHINKMX-XL32

Call

Condition: used, Year of construction: 2001, Technical details:

turning diameter: 33 mm

turning length: 330 mm

control: 840

total power requirement: 20 kW

weight of the machine ca.: 6 t

dimensions of the machine ca.: 3850,2000,2100 m

17 axes

Djdpfow D Hh Asx Ag Recb

3 revolvers with the powered tools

1 gantry with the driven tools

Main and counter spindle with C axes

Barfeeder

Machine On-time 58,133 hours

*

Listing

Dortmund

Dortmund

6,968 km

CNC turning and milling center

GILDEMEISTERNEF CT 60 mit angetriebenen WZ

Call

Condition: good (used), Year of construction: 1989, operating hours: 64,136 h, Centre height: 350 mm

Turning length: 1000 mm

Max. swing diameter over bed cover: 600 mm

Max. swing diameter over cross slide: 360 mm

Spindle bore: 107 mm

Dcedevr Eh Ejpfx Ag Rsb

Speed range: 16 – 3150 rpm

Feed range longitudinal & face: 0.5 – 5000 mm/min

Rapid traverse longitudinal & face: 9 m/min

Main drive: 30 kW

Dimensions of machine with chip conveyor (L x W x H): 5400 x 2200 x 2000 mm

Weight: 6400 kg

Accessories / Special features:

• CNC control GILDEMEISTER EPL 2 with TFT display

General description:

CNC manual input control system with program entry via function and numeric keypad. All information is entered in dialogue with the screen. Integrated menu technology with plain text display of all functions. Operator keypad, display, and electronic handwheel located within a separate chip guard housing.

The EPL control offers the following capabilities:

• Direct interactive program entry and editing by the operator through the EPL control without manual technological preparation

• NC programs in ISO/EIA format can be entered, output, or manually keyed in via the RS 232 serial interface

Machining cycles:

• Removal cycles for longitudinal, facing, and contour turning, including with allowance

• Thread cutting

• Undercuts as per DIN 509-Form E and F and DIN 76; grind stock programmable

• Axial and radial grooves as per DIN 471 and 472, including bottom finishing

• 90° radii and 45° chamfers

• Automatic cutter radius compensation for cycles, undercut, groove, radius, chamfer

Programming:

• Block-orientated, metric/inch, diameter for absolute entry, radius for incremental entry

• Full circle programming, subroutine technology, hide levels for program sections, zero point offset, mode selection via menu

Program entry and output:

• Interactive via guided menu or direct in dialogue

• Hydraulic 3-jaw chuck Ø 315 mm with through spindle bore Ø 80 mm

• Hinged chip conveyor

• 12-position tool turret VDI 40, 6 standard stations + 6 driven tool stations

• Coolant system

• RS 232 interface

• Electronic handwheel

• Electric foot switch for 3-jaw chuck and tailstock quill

• Lighting

• 12 various standard toolholders (to be finalized on site)

Overhauled servo drive for main spindle, 06/2025

Siegfried Volz Werkzeugmaschinen

Rüschebrinkstr. 151-153

DE - 44143 Dortmund - Wambel

Listing

Nördlingen

Nördlingen

6,744 km

CNC turning and milling center

DMG MoriCLX 550

Call

Condition: good (used), Year of construction: 2019, operating hours: 8,173 h, functionality: fully functional, turning length: 12,025 mm, turning diameter: 480 mm, spindle speed (max.): 3,250 rpm, travel distance X-axis: 308 mm, travel distance Y-axis: 120 mm, travel distance Z-axis: 1,240 mm, bar passage: 102 mm, overall weight: 7,200 kg, controller model: DMG MORI SLIMline Multi-Touch Control, control type: CNC control, CLX 550 V6

2-axis universal lathe

with driven tools

incl. C-axis, Y-axis, and counter spindle

Standard equipment:

Dsdpfx Agsxx Tcmo Rjcb

1. Ergonomic DMG MORI SLIMline operating panel

2. Main spindle A2-8 with AC motor, drive power 22 / 33 kW (100/40% DC), 3,250 rpm

3. Counter spindle A2-6 with ISM 52 synchro, drive power 13 / 14 kW, torque 171.5/192 Nm (100/40% DC), 5,000 rpm

4. 12-position servo turret, VDI 40 mounting with Trifix® precision interface and 12 driven tool stations per DIN 5480

5. Y-axis ± 60 mm

6. Chip tray

7. Hollow clamping device, max. bar capacity D 80 mm

8. Electronic handwheel

Drive power (100%/40% DC) 22/33 kW

Hydraulic clamping device with bar capacity diameter 102 mm, surcharge

Differential pressure clamping for main spindle

Bar package & interface option includes:

- Workpiece unloader for parts up to D 80 x 200 mm long (D 100 x 200 mm with option C-B7000G) Max. workpiece weight 4 kg

- Interface for bar loader or bar feed unit (DMG MORI standard interface)

- Hinged belt chip conveyor instead of chip tray

- 4-color signal tower

Recommended additional option: Double cartridge filter for coolant, especially for production environments with very high chip volumes.

Automatic workpiece ejector for counter spindle with internal coolant supply for clamping device flushing. Note: Option recommended for machines with workpiece unloader option.

External flushing for counter spindle, option recommended for machines with automation

Differential pressure clamping for counter spindle

Tailstock function for counter spindle, mechatronic force control programmable in the software (force 250-600 daN), including foot switch (only for CLX 550 V6)

Direct measuring system for X- and Y-axis (option only available for V4 and V6 versions)

Manual tool measuring device in the working area, brand Marposs

Documentation according to 'Technical Documentation Delivery List' – included in the machine price.

Software option: DXF import for converting DXF files into NC programs (SIEMENS control)

Tool monitoring system:

Easy Tool Monitor 1.0, monitors each cutting operation against a set limit. Simple learning function for determining the monitoring limit per tool and cutting operation; manual adjustment/correction possible.

Technology cycle:

Alternating speed (turning) for vibration-sensitive applications

Note: We offer flexible financing solutions for all machines as well as a professional relocation service. Dismantling, transport, and professional installation – everything from a single source. Billing based on individual terms and duration. Contact us for your personal offer.

Listing

Tipton

Tipton

7,615 km

CNC turning and milling center

HWACHEONHI- TECH 200B

Call

Condition: good (used), Year of construction: 2008, HWACHEON HI- TECH 200B CNC LATHE

MAKE HWACHEON, MADE IN SOUTH KOREA

MODEL HI TECH 200B

YEAR 2008

CONTROL FANUC O i-TB

SWING OVER BED 500.0 mm

SWING OVER SADDLE 390.0 mm

MAX MACHINING DIA 350.0 mm

MAX WORK LENGTH 400.0 mm

TRAVERSES (XZ) X AXIS: 195.0 mm

Z AXIS: 430.0 mm

CHUCK DIA 250.0 mm

MAX. SPINDLE SPEED 3,500 RPM

SPINDLE NOSE A2-8

SPINDLE BAR CAPACITY 76 mm

TURRET 12 STATIONS

MACHINE WEIGHT 4,500 kgs

PLUS

RENISHAW PROBE

PARTS CATCHER

TAILSTOCK

SWARF CONVEYOR

Dcedpfxst Urwhe Ag Rjb

MACHINE MANUALS

MACHINE IN GOOD WORKING ORDER

Listing

Germany

Germany

7,039 km

CNC Turning- and Milling Center

TRAUBTNX 65

Call

Condition: used, Year of construction: 2005, Technical details:

turning diameter: 275 mm

turning length: 900 mm

spindle passage: 65 mm

power capacity at 100 % load: 25/20 kW

spindle turning speed range: 1 - 5000 U/min

spindle diameter in front bearing: 110 mm

c-axis: 1 - 500 U/min.

number of workpiece supports: 4

tool turret: 1

x-axis: 290 mm

y-axis: 165 mm

z-axis: 360 mm

b-axis: 360 °

rapid speed: 18/30 m/min

number of tools: 2x2 + 2x2

number of driven tools: 2x2 + 2x2 mm

toolpiece turning speed range: 8000 / 2000 U/min

power capacity: 25% ED 5,8 kW

tool taper: TRAUB 60

tool turret: 2/3/4

x-axis: 170 mm

z-axis: 600/950 mm

y-axis: +/- 60 mm

rapid speed: 18/15/30 m/min

number of driven tools: 10 mm

toolpiece turning speed range: 1 - 6000 U/min

power capacity: 25% ED 5,8 kW

tool taper: DIN 69880 40 x 63

total power requirement: 95 kW

weight of the machine ca.: 16 t

dimensions of the machine ca.: 10,0 x 3,5 x 3,0 m

with CNC TRAUB TX 8i, Barloader TRAUB Stamag DNH61 / 3000,

Main and Sub spindle with C-axis

1 support with B-axis

Dcjdpfx Agjwp D Nbe Reb

3 turret supports

dust exhauster, coolant attachment with coalescence-seperator and chip conveyor

2 pc. 3-jaw chuck SMW KNCS-N 170-43

2 pc. HAINBUCH Spanntop chuck

40 pc. various tool holder non-driven

6 pc various tool holder driven

Spare parts package

*

Listing

Cascina Faustina

Cascina Faustina

6,860 km

2-axis CNC turning center

DAWEOOLYNX 200B

Call

Condition: used, Year of construction: 1998, operating hours: 8,700 h, functionality: fully functional, The used DAEWOO Lynx 200B 2-axis CNC lathe is a robust and fast numerically controlled lathe with a slant bed and flat guides, compact in size. It is equipped with a FANUC 21-T CNC control unit with LCD monitor, year of manufacture 1998, and complies with CE standards.

Dcedpex Nqliofx Ag Rob

Main features:

Max. swing over bed: 460 mm

Max. turning diameter: 280 mm

Max. turning length: 500 mm

Max. bar capacity: 51 mm

Spindle nose: ASA 6”

Spindle: max. rotation speed 4,500 rpm

Spindle motor power: 11 kW

Turret: 10 positions

Turning/boring tool size: 25×25 mm / Ø40 mm

Tailstock: quill diameter 65 mm, quill stroke 80 mm – MT4

Machine weight: 3,500 kg

The equipment includes the tailstock with programmable quill, tool presetting system, 3-jaw hydraulic chuck (which will be supplied in place of the manual chuck), and operating and maintenance manuals.

Listing

Germany

Germany

6,878 km

CNC Turning- and Milling Center

INDEXG300

Call

Condition: used, Year of construction: 2003, Technical details:

turning diameter: 270 mm

weight of the machine ca.: 6,5 t

max. swing diameter: 590 mm

with automatic loading and unloading system, chip conveyor

G300 with "spindle bore clamping capacity 90mm" in tailstock version

Dedpfjx Dlhljx Ag Recb

The machine has no driven tools. The information in the circuit diagram refers to the rotary drive for indexing the turret, not to driven tools.

*

Listing

Tiefenbronn

Tiefenbronn

6,869 km

CNC turning and milling center

MiyanoABX-64SY

Call

Condition: good (used), Year of construction: 2009, operating hours: 48,570 h, functionality: fully functional, Equipment: documentation/manual, rotational speed infinitely variable, Make: MIYANO

Model: ABX-64SY

Dsdpfx Agexzrpws Recb

Year of manufacture: 2009

FANUC 31i control

Driven tools

Turret

C-axis

Parts conveyor belt

Chip conveyor

Parts gripper

Multifeed bar loader

Listing

Chapel Brampton

Chapel Brampton

7,541 km

CNC turning and milling center

CMZTD35Y-1350

Call

Condition: excellent (used), Year of construction: 2018, operating hours: 26,811 h, functionality: fully functional, machine/vehicle number: -, turning length: 1,350 mm, turning diameter over cross slide: 715 mm, turning diameter: 550 mm, spindle motor power: 48 W, spindle speed (max.): 3,000 rpm, spindle bore: 106 mm, travel distance X-axis: 380 mm, travel distance Y-axis: 80 mm, travel distance Z-axis: 1,350 mm, mount diameter: 12 mm, total height: 2,346 mm, total length: 4,088 mm, total width: 2,129 mm, swing diameter over bed slide: 950 mm, overall weight: 10,400 kg, High specification machine with Fanuc 32iTB control. Many options including SMW Autoblok steady rest on programable Servo base, coolant through steady, high pressure coolant, enlarged left hand door to allow 920 mm swing workpiece (950 mm max). Various other options. New cost in 2018 over £200k.

Dcsdpfxevz Ab Us Ag Rsb

Listing

Burgoberbach

Burgoberbach

6,740 km

CNC turning-milling center 6 AGW

GildemeisterCTX 310 Eco (nur 3.350 h)

Call

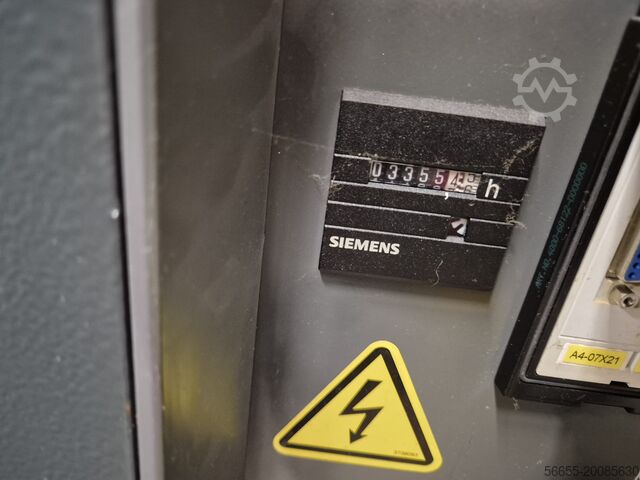

Condition: excellent (used), Year of construction: 2012, operating hours: 3,355 h, functionality: fully functional, turning length: 450 mm, turning diameter: 200 mm, spindle speed (max.): 5,000 rpm, spindle bore: 51 mm, travel distance X-axis: 160 mm, travel distance Z-axis: 450 mm, overall weight: 3,800 kg, For sale is a CNC lathe from the brand Gildemeister, model CTX 310 Eco.

The machine is in excellent condition and ready for immediate use.

Technical specifications:

Year of manufacture: 2012

Operating hours: 3,355 h (see picture)

Control: SIEMENS SINUMERIK 810D Powerline

Max. turning diameter: 200 mm

Max. swing diameter over bed: 330 mm

Max. turning length: 450 mm

X-axis travel: 160 mm

Main spindle speed: 5,000 rpm

Dedsxf T N Tepfx Ag Rocb

Spindle bore: 51 mm

Turret: 12-station turret (VDI 30)

Live tooling: 6 driven tool stations

Live tool speed: approx. 4,500 rpm

Rapid traverse X/Z: 30/30 m/min

Dimensions: approx. 4200 mm x 1700 mm x 2300 mm

Machine weight: approx. 3,800 kg

Chip conveyor included in the offer.

Tool holders not included in the offer (can be offered additionally).

Transport and loading can be organized across Europe upon request, at extra cost.

Prices are exclusive of VAT.

Inspection by appointment possible. Contact us — our team is happy to assist you!

Trade-in or exchange possible!

Machinery trading

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MORE.

Are you looking for a high-quality yet affordable metalworking machine for your production? Or do you wish to sell yours?

For more information or contact options, please visit our website.

Listing

Lüneburg

Lüneburg

6,777 km

CNC Turning and milling center

Nakamura-TomeNTJX

Call

Condition: used, Year of construction: 2008, functionality: fully functional, Turning / milling center with counter spindle

with 10 CNC axes (X1, X2, Z1, Z2, Y1, Y2, B1, B2, C1, C2)

Dcsdpfx Aox I N N Rsg Rob

Control: FANUC 31:iA

Main Spindle

Power: 15/11 kW

bar material dia.: 51 mm

spindle revolution: 5.000 min-1

Counter Spindle

Power: 11/7,5 kW

bar material dia.: 51 mm

spindle revolution: 5.000 min-1

Turning and milling spindle

Power: 7,5/3,7 kW

Turning and milling spindle speed: 12.000 min-1

max. rotation length turret bottom: 1.005 mm

Slide cross X1 / X2 / Z1 / Z2 / B2: 455 / 222,5 /1.090 / 1.005 / 1.008 mm

Slide cross Y1 / Y2: +/- 70 / +20, -50 mm

Swivel range B1 axis: +/- 95 °

Linear rack magazine incl. support robot

CNC support steady rest

Coolant cyclone filter system incl. 2 pcs. coolant pumping

spindle oil cooler

Listing

Chomutov 1

Chomutov 1

6,546 km

CNC turning and milling center

ColchesterAlpha 2800XS

Call

Condition: used, Year of construction: 2011, Manufacturer: Colchester

Model: Alpha 2800XS

Year of manufacture: 2011

Control system: Fanuc 21i-TB – a proven platform for precise and fast machining control

Turning diameter over bed: 800 mm – suitable for large workpieces

Turning diameter above the slide: 500 mm

Maximum turning length: 1500 mm – ideal for long parts

Dcedpfx Agox Rra Ro Reb

C-axis: Yes – allows advanced operations such as off-axis milling and drilling

Listing

Torbole Casaglia

Torbole Casaglia

6,770 km

CNC turning and milling center

MazakINTEGREX I-400 ST

Call

Condition: used, Year of construction: 2015, functionality: fully functional, Type of control Mazatrol Matrix 2

Max. workable diameter ( Upper turret) Ø 658 mm

Max. workable diameter ( Lower turret) Ø 420 mm

X Axis Travel 260 mm

Y axis travel 260 mm

Z Axis travel 1,585 mm

W-Axis Travel 1,539 mm

X2 axis travel 230 mm

Z2 axis travel 1,388 mm

B axis -30° ~ 210°

Spindle connection Capto C4

Self centering spindle 12"

Spindle bar passage 102 mm

Spindle speed 3,300 rpm

Spindle power 30 Kw

Spindle nose A 2-8

Self centering secondary spindle 10"

Secondary spindle bar passage 80 mm

Secondary spindle speed 4,000 rpm

Secondary spindle power 18,5 Kw

High pressure 70 Bar

Milling spindle rotation speed 12,000 rpm

Tool turret 9 positions

Probe Renishaw

Dcsdpfx Ajx Rzchjg Rob

Equipment Chip conveyor

Listing

Jakling

Jakling

6,410 km

CNC turning and milling center

EMCOMAXXTURN 65-G2 SMY

Call

Condition: like new (used), Year of construction: 2022, operating hours: 800 h, functionality: fully functional, turning length: 610 mm, turning diameter over cross slide: 500 mm, turning diameter: 725 mm, spindle speed (max.): 5,000 rpm, spindle bore: 65 mm, travel distance X-axis: 260 mm, travel distance Y-axis: 80 mm, travel distance Z-axis: 610 mm, rapid traverse X-axis: 30 m/min, rapid traverse Y-axis: 15 m/min, rapid traverse Z-axis: 30 m/min, feed length X-axis: 260 mm, feed length Y-axis: 80 mm, feed length Z-axis: 610 mm, torque: 250 Nm, bar passage: 65 mm, Equipment: documentation/manual, rotational speed infinitely variable, For sale: As-new EMCO MAXXTURN 65-G2 SMY, year of manufacture 2022, equipped with Siemens Sinumerik ONE CNC control featuring ShopTurn!

CNC turning center for complete machining of turned/milled parts.

Key features include:

- Integrated spindle motors, counter-spindle, water-cooled (preloaded roller guides) with Y-axis, operative on main and sub-spindle

- Latest SINUMERIK ONE control with ShopTurn conversational programming

Main Spindle:

- Max. bar capacity: 65 mm

- Max. torque: 250 Nm

- Speed range: 0–5000 rpm

Sub-Spindle:

- Drive power: 22 kW

- Max. torque: 130 Nm

- Speed range: 0–7000 rpm

Tool Turret:

- 12-station VDI 30 radial turret with directional logic for up to 12 driven toolholders

- Max. drive power: 6.7 kW

- Max. torque: 25 Nm

- Max. speed: 5000 rpm

Y-Axis:

- Travel: ±40 mm

Additional Equipment:

- Hollow chuck cylinder incl. draw tube

- C-axis for both spindles

- Sinumerik ONE / OPERATE control

- 22" multi-touch display

- ShopTurn, 3D simulation, remnant material detection

- USB interface

- Electrical cabinet climate control

Djdpfx Aex E Dncjg Rocb

- Coolant system incl. pump (3.5 bar)

- Chuck flushing (extra pump 3.5 bar)

- Parts ejector and flush through sub-spindle

- Hydraulic unit

- Interface for chip conveyor

- Documentation and CE certificate

- Control languages: German / English

- Electronic handwheel

- EMCO TOOL BREAKAGE AND WEAR MONITORING / SINUMERIK ONE

- Alternating spindle speed

- Sub-spindle as tailstock: This cycle allows use of the sub-spindle with mounted live center for workpiece support, permitting shaft machining even on machines without a conventional tailstock. Max. support force limited to 50% of maximum axis force.

- EMCO PROFI-NET ROBOTIC INTERFACE: Connection interface for robot integration via HARTING connector. Signal exchange via Profinet. Safety signals: 2-channel/potential-free.

- Digitalization package for Sinumerik: Condition monitoring

- SIEMENS ONE INTERFACE for connection to MDE/BDE systems. Standard info includes:

• Machine on - AUX ON

• Automatic mode

• Production mode - program active

• Program running and override between 95–105%

• Part count pulse (M30)

• Programmable pulse (M300)

- 3D machine data / MT65-G2: 3D model of the machine included

Pneumatically actuated finished parts catcher for gentle unloading of finished components. Parts are transported to a collection box (standard) or onto a conveyor belt (optional).

- Max. finished part length: 175 mm

- Max. finished part diameter: 65 mm

- Max. finished part weight: 4.5 kg

INTERFACE SL1200 HT65-DT/TT + MT65-1000: For connecting the EMCO SL1200 bar feeder.

Etc.

The machine is immediately available!

Trust Seal

Dealers certified through Machineseeker

Listing

Germany

Germany

6,879 km

CNC Turning- and Milling Center

MONFORTSRNC 500 AC

Call

Condition: used, Year of construction: 2001, Technical details:

turning diameter: 500 mm

turning length: 1000 mm

control: Siemens 840 D

spindle: 42 / 28 kW

spindle turning speed - stepless: 31 - 4000 1/min

max. torque on the spindle: 345 Nm

c-axis: 360000 x 0,001°

feeds -stepless-: mm/min

rapid traverse: mm/min

turret stations / rotary tool stations: 12/12 VDI 40

RPM of rotary tools: 2000 1/min

diameter of quill: 90 mm

quill stroke: 80 mm

tailstock quill taper ISO: SK 30

Tailstock Travel: 600 mm

Power rotary tools: 3,5 kW

: 22,5 Nm

Rotary tool holders: 4 ax./ 4 rad.

spindle passage: 66 mm

total power requirement: 30 kW

Dcedpex I Ir Refx Ag Rjb

weight of the machine ca.: 7,5 t

dimensions of the machine ca.: 8x 3 x 4 m

Accerories

Power Chuck

Programmable Tailstock

Chip conveyor

Listing

Düsseldorf

Düsseldorf

7,016 km

CNC turning and milling center

EMCOEMCOTURN E 45

Call

Condition: like new (used), Year of construction: 2018, Technical Data:

• Swing diameter over cross slide: 430 mm (max. turning diameter 220 mm)

• Turning length: max. 670 mm

• Spindle bore (clearance diameter): 45 mm

• HS spindle interface DIN 55026 A2-5

• Main drive power: 13 kW

• Max. torque: 78 (100) Nm

• Speed range: 0–6300 rpm

• Counter spindle interface: DIN 55026 A2-4

• Number of tools: 12 driven tools, max. speed: 0–6000 rpm

• Tool holder: VDI 25

• Pressure boost station E45 for central coolant system; centrifugal pump 14 bar; lifting pump min. 1.5 bar

• Chip conveyor: hinge belt conveyor, discharge height 1200 mm

• Swing loader Emcoturn E45 with loading and unloading system; 2-finger parallel gripper / 90° rotating module

• Belt conveyor for RT parts feeding: length 1300 mm / width 567 mm; chain pitch 27.1 mm (1800L)

• Control: Siemens 828 D

⸻

• Connected load: approx. 46 kVA

• Voltage: 400 V / 50 Hz

• Weight: approx. 4,300 kg

Dodpfxswl Uu Ho Ag Recb

• Space requirement: approx. 15 m²

Listing

Neuss

Neuss

7,023 km

CNC turning and milling center

SAMSUNG SMECSAMSUNG SMEC PL-60L

Call

Condition: used, SAMSUNG SMEC PL-60L Ø1,030 x 3,200 mm / 2016 Model

Machining Capacity / Fanuc Oi TD CNC Controller

• Swing over bed: Ø 1,030 mm (32 inch hydraulic chuck)

• Swing over cross slide: Ø 800 mm

Dodpfjx Scprjx Ag Rscb

• Maximum turning diameter: 530 mm

• Maximum machining diameter: Ø 900 mm

• Maximum turning length: 3,200 mm (Ø 45~310 mm with hydraulic steady rest)

• Maximum chuck machining diameter: 139.5 mm

Axis Travel

• X-axis travel: 470 mm

• Z-axis travel: 3,270 mm

Spindle

• Spindle bore: 1,500 mm

• Spindle nose size: 21"

• Spindle nose type: A2-15

• Spindle through hole diameter: Ø152 mm

Turret (Standard)

• Number of tool stations: 12 (Standard)

• Tool shank size: □32 mm

• Boring bar shank size: Ø80 mm

Tailstock

• Tailstock travel: 3,270 mm

• Quill diameter: Ø180 mm

• Tailstock taper: MT-6 (built-in)

• Tailstock stroke: 150 mm

Power & Installation

• Power requirement: 65 kVA

• Machine dimensions (L × W): 7,400 × 2,760 mm

• Machine weight: 22,000 kg

Listing

Bremen

Bremen

6,883 km

CNC turning and milling center

TRAUBTNX 65/42 DGY

Call

Condition: good (used), Year of construction: 2012, functionality: fully functional, Description follows

Dsdsx A Hdfopfx Ag Recb

We make it easier for you to find: "cnc turning center"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Cnc Turning Center (21,218)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

- Center

- Center Lathe

- Cnc 5 Axis Machining Center

- Cnc Center

- Cnc Center Lathe

- Cnc Center Machining

- Cnc Fräsen Center

- Cnc Horizontal Machining Center

- Cnc Machining Center

This may be of interest to you