Used Cnc Milling Center for sale (24,070)

Bergisch Gladbach

Bergisch Gladbach CNC turn-mill center

OkumaMacturn 30 W OSP 7000L

Aach

Aach CNC turn-mill center

GILDEMEISTERNEF 520

Dortmund

Dortmund CNC turning and milling center

GILDEMEISTERCTX 600-2000

+44 20 806 810 84

Neubrandenburg

Neubrandenburg CNC turning and milling center

GildemeisterDMG CTX beta 800

Douvrin

Douvrin CNC turning and milling center

DanobatDANOCENTER NA-750

Discover more used machines

Denzlingen

Denzlingen CNC turning and milling center

MazakQuick Turn 200MSY SmoothG

Aflenz Land

Aflenz Land CNC turning and milling center

OkumaMultus B300-W

Częstochowa

Częstochowa CNC turning and milling center

MAZAK NexusVCN-510C

Burgoberbach

Burgoberbach CNC turn-mill center 12 AG 2 spindles

MazakQuickturn Nexus 200-II MS

Burgoberbach

Burgoberbach CNC turn-mill center 12 AG 2 spindles

MazakQuickturn Nexus 200-II MS

Burgoberbach

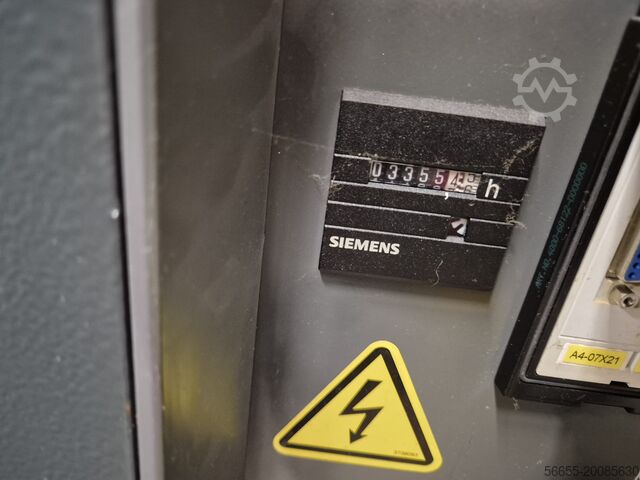

Burgoberbach CNC turning-milling center 6 AGW

DMGCTX 310 Eco (nur 3.350 h)

Burgoberbach

Burgoberbach Milling Machine / Machining Center CNC

MAHOMH 300 C

Savonlinna

Savonlinna CNC turning and milling center

DMG MORIGMX 200

Schwäbisch Gmünd

Schwäbisch Gmünd CNC turning and milling center

MonfortsRNC 4, 5 und 7

Kirchheim bei München

Kirchheim bei München CNC turn-mill center

DMGMilltap 700

Kirchheim bei München

Kirchheim bei München CNC turn-mill center

GildemeisterCTX 320 linear V 3

Jakling

Jakling CNC turning and milling center

Mori Seiki, DMGNLX 2500SY/700

Jakling

Jakling CNC turning and milling center

EMCOHyperturn 665 MC Plus

Werlte

Werlte CNC turning and milling center

OkumaMULTUS U4000 1SC 1500 BigBore

Sonnenbühl

Sonnenbühl CNC turn-mill center

HAASSL20HE

Hessisch Lichtenau

Hessisch Lichtenau CNC vertical machining center, VMC, BAZ, milling machine, milling, milling center

HURCOBMC 25 /M - Ultimax 3

Rīga

Rīga CNC turning and milling center

DOOSANMX2100ST

Czech Republic

Czech Republic CNC turning and milling center

MAZAKNEXUS 200 MS

Oestrich-Winkel

Oestrich-Winkel CNC turn-mill center

DMGCTV 400 V3

Zona Industriale di Robassomero

Zona Industriale di Robassomero CNC turning and milling center

GildemeisterSprint 42

Used Cnc Milling Center (24,070)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

+44 20 806 810 84