Used Balancer for sale (819)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Duxford

Duxford

7,469 km

Sartorius ENTRIS2201l-1S Balance +Tare Printer

SartoriusCubis MCE10202S-2S00-0

Call

Condition: used, This listing is for a Sartorius Cubis MCE10202S-2S00-0 Balance with unit is in full working condition and is ready for immediate release.

Experience unparalleled precision and versatility in laboratory measurements with the Sartorius Cubis MCE10202S-2S00-0 Balance, a standout model in the innovative Cubis II series.

Key Features:

High Capacity and Readability: With a capacity of 10,200 g and a readability of 0.01 g, this balance is ideal for weighing larger samples with utmost accuracy.

Exceptional Reproducibility: Achieve consistent results with a reproducibility of ±0.007 g, ensuring reliable data across multiple measurements.

Impressive Linearity: Maintains accuracy with a linearity specification of ±0.02 g, making it suitable for critical weighing tasks in demanding environments.

Spacious Pan Dimension: The balance features a spacious weighing pan measuring 8.1 in x 8.1 in (206 mm x 206 mm), accommodating a variety of sample sizes comfortably.

Gsdpfjxxzaajx Aaloin

User-Friendly Display: Equipped with an MCE Touch Screen Back lit display, it offers intuitive navigation with manual level control and a motorized internal calibration feature for convenience.

Additional Information:

Modular Weighing System: The Cubis II series allows for individual configuration from various components, enabling users to adapt the balance to specific weighing tasks seamlessly.

Versatile Applications: This balance is suitable for a broad range of laboratory applications, including research, quality control, and educational settings, making it a versatile tool for scientists and educators alike.

Range of Options: The Cubis II series boasts a selection of premium laboratory balances with maximum loads ranging from 2.1 g to 70 kg and readability options between 0.1 μg to 1 g, providing tailored solutions for different measurement needs.

Listing

Duxford

Duxford

7,469 km

Sartorius LA820-0CE Balance with Printer

SartoriusLA820-0CE

Call

Condition: used, This listing is for a Sartorius LA820-0CE Balance with Printer.

The unit is in full working condition and is ready for immediate release.

Achieve unmatched precision in your laboratory with the Sartorius LA820-0CE Balance with Printer. This top-loading balance is expertly designed to cater to a variety of weighing applications, combining high-resolution measurements with advanced functionalities.

Key Features:

Capacity and Readability: With a capacity of 820 g and a readability of 0.01 g, this balance ensures accurate measurements for both small and larger samples.

Diverse Weight Modes: Offers multiple weight modes including Carats, Grains, Milligrams, Pounds, Ounces, Pennyweight, Grams, and Troy Ounces, allowing you to choose the most suitable measurement unit for your needs.

Advanced Functions: Features practical functionalities such as Averaging, Formulation, and Percent Weighing, streamlining complex weighing processes.

Gedpfx Aasxxza Holein

Enhanced Features: Equipped with Parts Counting for inventory management, RS-232c connectivity for data transfer, and Internal Calibration to maintain accuracy effortlessly.

Sturdy Construction: Built with a solid diecast metal base and a stainless steel weighing pan, featuring a Magnetic Force Motor Monolithic Weigh Cell for durability and precision.

Automatic Calibration: Motorized automatic internal calibration ensures that the balance remains accurate over time with little user intervention.

Communication Options: RS-232 connectivity allows for easy integration with other devices, and you can purchase an aftermarket DB9 RS-232 Adaptor Converter with USB Cable for enhanced connectivity.

Compact Platform Size: The weighing platform measures 8.6 x 7.9 inches, ideal for fitting into various lab setups without sacrificing space.

Power Requirements: Comes with a 120V AC adaptor, so you can start using it right away.

Manufacturer Warranty: Enjoy peace of mind with a 3-year warranty included.

Durability: IP54 rated, providing protection against harmful dust deposits and spills, making it suitable for rigorous lab environments.

Printer Specifications:

Type: Data Printer designed for compatibility with CPA Balances, Extended Balances, and Moisture Analysers.

Compact Dimensions: Measures 230 x 158 x 80 mm, making it a convenient addition to your lab setup.

Inclusions: Comes complete with an interface cable, a paper roll, and 4 rechargeable batteries, ensuring you have everything needed to get started.

Data Transfer Options: Allows for automatic or manual data transfer, catering to different workflow preferences.

Flexible Statistics Program: The built-in statistics program can be individually selected to meet your specific needs, enhancing your data analysis capabilities.

Listing

Duxford

Duxford

7,469 km

Sartorius BP 2100 S Balance with Printer

SartoriusBP 2100 S

Call

Condition: used, This listing is for a Sartorius BP 2100 S Balance with Printer.

The unit is in full working condition and is ready for immediate release.

The Sartorius BP 2100 S Analytical Balance is expertly designed for precision weighing applications, making it an essential tool for laboratories, quality control, and research settings. Its large top-loading design ensures easy placement and removal of samples, while its advanced features provide reliable and accurate measurements for various scientific needs. With a maximum capacity of 2100 grams and a readability of 0.01 grams, this analytical balance meets the rigorous demands of precise weighing.

Key Features:

High Precision Weighing: With a maximum capacity of 2100 grams and a readability of 0.01 grams, the BP 2100 S delivers exceptional accuracy, making it suitable for a wide range of applications.

User-Friendly Top-Loading Design: The balance features a spacious top-loading design that allows for quick and easy access, streamlining sample handling and improving workflow efficiency.

Built-In Printer: The integrated printer enables users to conveniently print weight measurements and other important data directly from the balance, simplifying record-keeping and enhancing data management.

Versatile Applications: Ideal for laboratory environments, quality control, and research applications, the BP 2100 S is versatile enough to meet the needs of various industries.

Robust Construction: Built with high-quality materials, this balance ensures durability and longevity, making it a reliable choice for everyday use in demanding settings.

Easy Calibration: The balance offers straightforward calibration procedures, ensuring ongoing accuracy and performance.

Key Specifications:

Model: Sartorius BP 2100 S

Maximum Capacity: 2100 grams

Gedpfxoxx Adge Aalsin

Readability: 0.01 grams

Design: Top-loading for easy sample access

Printer: Built-in for direct printing of weight measurements and data

Applications: Laboratory analysis, quality control, research settings

Power Supply: Mains powered for consistent performance

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Duxford

Duxford

7,469 km

Kern PCB 250-3 Balance

KernPCB 250-3

Call

Condition: used, This listing is for a Kern PCB 250-3 Balance.

The unit is in full working condition and is ready for immediate release.

The Kern PCB 250-3 is a Precision Laboratory Balance that is highly accurate, fully programmable and comes with a range of advanced features for precise record keeping and weighing.

The balance is suitable for weighing and counting even the smallest parts. The balance is supplied with an 81mm weighing plate.

A built-in recipe function makes determining the exact measurements of a mixture as easy as possible. This mode will allow you to weigh the specific parts of a mixture, record each value and recall your measurements afterwards for reference.

Pre-tare function - manually subtracts known container weights

Fully programmable - configure the balance to measure in special units such as length of thread g/m, paper weight g/m² or similar

Percentage determination - store a given weight value (100%) and determine deviations from the target value

CAL EXT function - adjust the balance's accuracy with an external adjustment weight

RS232 interface - allows the balance to interface with a PC or printer

GLP/ISO record keeping of weighing data with date, time and identification number

Dedicated Recipe function logs the weight of a tare container plus the recipe's ingredients

% Determination mode - calculates % deviations from a target value (100%)

Godpfx Ajxx Atzjalein

Vibration-free weighing - filters out vibrations to maintain stable weight results

Supplied with a weighing range of 250g

Manufacturer's part: Kern PCB 250-3

Listing

Duxford

Duxford

7,469 km

Oxford XB220A-i Balance with Printer

OxfordXB220A-i

Call

Condition: used, This listing is for a Oxford XB220A-i Balance.

Gijdpfx Aaexx At Uelen

The unit is in full working condition and is ready for immediate release.

Features -High Precision Technology

-Easy Operation draft Shield

-Maximum User Friendliness

-Large Vacuum Fluorescent Display

-Die-cast Aluminum Housing

-lP65 protection available against ingress of dust and water available

Capacity: 220g

Discover more used machines

Listing

Duxford

Duxford

7,469 km

Ohaus Scout Pro Portable balance Sp4001

OhausScout Pro Portable balance Sp4001

Call

Condition: used, This listing is for the Ohaus Scout Pro Portable balance Sp4

The unit is in full working condition and is ready for immediate release

The Ohaus Scout Pro SP4001 is an intuitive, durable portable electronic balance designed for a wide range of laboratory, industrial, and educational applications. This balance is easy to operate with minimal instruction and offers advanced features for precise and reliable weighing.

Key Features:

Simple Operation: The Scout Pro digital scales are incredibly easy to operate, featuring a high-contrast LCD display that ensures readability from any angle.

Giodpfsxv A S Sex Aalen

Durable Design: Sealed front panel, molded spill ring, and a stainless steel platform protect the balance from spills and make it easy to keep clean.

Multiple Weighing Units: Includes grams, kilograms, pounds, ounces, and a combined pound:ounce display. Switch between units with just the touch of a button.

Multiple Application Modes:

Enhanced Parts Counting: Allows for recalculating the average piece weight.

Percentage Weighing: Ideal for comparing sample weights to a reference weight.

Totalization: Allows repeated summation to the limit of the display, not just the capacity of the balance.

Display Hold: Perfect for weighing large packages, only available in the Ohaus Scout Pro series.

Weigh Below Hook: An integral hook allows for below-balance weighing, critical for density or specific gravity determination.

USB/RS232 Connectivity: Features an easy-to-install USB or RS232 interface for quick data connection to a PC or printer, a feature unique to the Ohaus Scout Pro in this price range.

Battery or AC Power: Powered by 4 AA batteries, offering up to 40 hours of operation with auto shut-off, or can be powered through the included AC power pack.

Physical Lock Switch: The lock switch helps reduce operator error by locking the balance into a specific configuration.

Security Bracket and Shipping Lock: Comes with an integral security bracket and a shipping lock to protect the weighing mechanism during transport.

Specifications:

Maximum Capacity: 4,000 g

Readability: 0.1 g

Pan Size: 5.6 in x 6.5 in (142 mm x 165 mm)

Linearity: ±0.1 g

Stabilization Time: 3 seconds

Dimensions: 8.3 in x 2.1 in x 7.5 in (210 mm x 54 mm x 192 mm)

Weight: 4 lb (1.8 kg)

Power Supply: 4 AA batteries or AC adapter (included)

Construction: ABS housing with stainless steel platform

Units of Measurement: g, kg, oz, lb, lb:oz, t, dwt

Listing

Odesa

Odesa

5,211 km

Balancing machine modernization kit

PAK-1 Unbalance Measuring Unit

Call

Condition: new, PAK-1 Unbalance Measuring Unit is designed to modernize your balancing machine.

A balancing machine has a long mechanical life, but prolonged use leads to gradual failure of electronics and measuring instruments, causing problems with spare parts and lack of technical support.

Minimize downtime and ensure the reliability of your balancing machine by upgrading it with a new advanced measuring unit.

The PAK-1 unbalance measuring unit works in all balancing machines of most existing designs and manufacturers.

Confidence in results and ease of use: Easy to set up and work with, our devices do not require any special theoretical knowledge.

Wide range of functions for your balancing machine: The use of modern microprocessor technology and many years of experience of our developers allows us to implement functions that were previously unavailable to other manufacturers.

Your machine complies with ISO 21940: Balancing machines equipped with the PAK-1 unbalance measuring unit fully meet the precision requirements of modern standards.

HIGHLIGHTS

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• Easy to learn working skills and maintenance for any employee.

INCLUDES: 1) vibration sensor signal processing unit, 2) fanless industrial computer with touch screen, 3) new vibration and speed sensors, 4) metal protected cable set.

SEQUENCE OF WORKS for modernization of the measuring unit

- Replacement of the existing measuring system with the balancing complex PAK-1 based on an industrial computer;

- Installation of new vibration sensors and rotor speed sensor

- Replacement of all connecting cables;

- Adjustment of the measuring unit on the balancing machine;

- Training of personnel with skills to operate the machine.

VTM GROUP offers to upgrade your balancing machine.

We repair and modernise various old balancing machines of all types from all manufacturers.

It's cost effective.

An alternative to buying a new balancing machine in 95% of cases.

Urgent.

Work can be done at customer site within 1-2 days.

New components for modernization of your machine:

• Installation of new measuring system and vibration and speed sensors.

• Installation of new electrical equipment

Giedsq Ttn Djpfx Aalon

• Manufacturing or repair of the rotation drive

• Manufacturing of new rollers

Every business is different. Let's discuss your task.

We can offer a solution for any balancing machine.

Please contact us to get the best offer!

👇

Listing

Marxzell

Marxzell

6,893 km

Dittel MBA 2000 Mechanic balance machine

DittelF20367

Call

Condition: new, For sale is a Dittel MBA 2000 Mechanic balance machine.

The item is new and fully functional.

Item number: F20367

Serial number: 356-0629

Part No.: 816/118 B

Giodpfx Aajpky U Esljn

Shipping or pickup can be arranged at any time.

If you have any further questions or are interested just contact me.

Listing

Odesa

Odesa

5,211 km

Turbo balancing machine

VTM GroupSBR-10

Call

Condition: new, VSR turbocharger high-speed balancing machine SBR-10

SBR-10 professional specialised equipment for high-speed balancing of assembled turbo cartridges. Equally useful for car and truck turbocharger.

The machine was designed for entry level turbocharger repair workshop, including medium re-manufacturers.

It solves a wide range of tasks that repair centres face on a daily basis.

The SBR-10 simulates the same testing and balancing conditions as the turbocharger on the vehicle, this allows the quality of the repair to be guaranteed. It also allows checking turbocharger for oil leakage.

A well-balanced turbocharger has a long service life which reduces the return rate of turbochargers and helps to build up your reputation.

HIGHLIGHTS

Mounting the cartridges on their standard surfaces (as on the engine) allows the installation of almost all turbochargers.

Wide range of accessories and adapters for installing any kind of turbos

Includes adapters for installing turbochargers with lower oil inlet and reverse rotation turbines

Oil system with oil heating allows to recreate similar conditions to the real one during balancing.

The turbocharger rotation and measurement is automatic. The cycle includes acceleration to maximum speed, measurement during the cycle, and air shutdown.

Emergency shutdown is provided in case of extreme vibration increase, which prevents cartridge destruction even in case of assembly errors

Automatic cycle allows to carry out vibration measurement in a short and sufficient period of time.

Vibration measurement of the turbocharger housing - up to a value of 10G, which 2 times better than other analogs.

Gsdpfxsnfvmhj Aalein

KEY FEATURES

• car and truck turbocharger balancing

• Any turbocharger installation

• All type turbocharger adapters

• Reverse rotation adapters

• Balancing speed up to 300 000 rpm

• Fast oil heater and temperature regulation

• 3-stage oil filtration

• Real-time unbalance measurement

• Automatic cycle turbocharger balancing

• An industrial fanless touch screen pc control system

• Access to self-editing of the data base

• Creation and printing of reports on turbocharger balancing

SPECIFICATIONS

Maximum compressor wheel diameter 120 mm

Maximum rotation speed 300 000 rpm

Pneumatic system operating pressure 0,8 – 1,0 MPa

Minimum air receiver volume 1000 L

Power supply 220V, 1Ph, 50Hz

Power input 1,5 kW

Dimensions 1120 х 780 х 1274 mm

Weight 285 kg

We manufacture fuul range turbo repair equipment.

Please contact us to get more info!

👇

Listing

Odesa

Odesa

5,211 km

Horizontal Dynamic Balancing Machine

9D717

Call

Condition: new, The 9D717 balancing machine is a versatile and reliable tool for balancing a wide range of rotors from 15 to 1500 kg.

This machine is capable of balancing different types of rotors, including inboard and outboard cantilever rotors, rotors on special mandrels and rotors in their own bearings.

The machine's design is simple yet functional, allowing it to easily balance armatures, generator rotors, impellers and fan wheels, even with large initial imbalances. In addition, the machine can balance rotors in their own bearings, saving repair time and preventing damage to the rotor trunnions.

It is suitable for determining and eliminating unbalance on rotors of electric motors, metallurgical gears, screws and printing equipment.

The 9D717 balancing machine is also capable of balancing disc-type parts such as impellers and smoke pump impellers, as well as correcting unbalance on shaft-type parts such as threshing drums and combine rotors.

Overall, this machine is highly versatile and effective in balancing various types of rotors, making it ideal for repair and production shops.

HIGHLIGHTS

• The specially designed rollers use advanced patented “Exact Barrel” grinding technology and are mounted on precision bearings.

• The monolithic design of the supports and base eliminates vibration losses during balancing by reducing the number of "oscillating system" elements.

• Allows large initial unbalances to be measured without destroying the machine, and rotor unbalance to be corrected directly on the machine.

• The low natural resonance frequency of the supports allows the rotor to be balanced at low speeds.

• The width of the support rollers and roller block allows the installation of rotors with very short rotor bearing journals. The modular design allows rotors with unusual configurations to be mounted using spacers or tools.

• The height of the roller block is adjustable, allowing rotors with different journal diameters to be balanced.

• The belt drive has a patented "Long stroke" design that allows any rotor to be rotated using only two drive belts.

• The frequency converter drive provides smooth acceleration and deceleration of the electric motor and infinitely variable speed control of the rotor.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• Easy to learn working skills and maintenance for any employee.

SPECIFICATIONS

Weight range of balanced rotors 15 - 1500 kg

Maximum rotor diameter (above the bedding) 1800 mm

Distance between centres of rotor supports 360 – 3000 mm

Support type Rollers

Transmission element for rotor rotation Belt / Cardan

Minimum achievable residual specific unbalance 0.4 g*mm/kg

Rotor speed range 300 – 1500 rpm

Electric motor power 7.5 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

Gisdpfspdpn Uex Aalon

👇

Listing

Odesa

Odesa

5,211 km

Lightweight balancing machine

9A713 (30kg)

Call

Condition: new, workpiece weight (max.): 30 kg, rotor diameter: 700 mm, The BALANCING MACHINE 9A713 is a universal horizontal-axis balancing machine designed for light rotors up to 30 kg in various configurations.

This series incorporates innovative technical solutions, ensuring that balancing is straightforward and accessible. With high performance and functionality, the 9A713 is popular in manufacturing across multiple industries.

Originally designed for small series and individual production, its versatility and productivity have also made it a favorite in various repair shops.

HIGHLIGHTS

• High balancing accuracy 0,4 gmm/kg = 0,4 µm

• Advanced Rollers: Specially designed rollers with advanced grinding technology mounted on precision bearings.

• Bearing Design Options: Hard-bearing design suitable for small rotors, with optional soft bearing support available.

• Belt Drive System: High degree of belt tensioning repeatability with a micro-tuning function for precise belt tension adjustment.

• Quick Changeovers: Easy access to support rollers for quick rotor reinstallation and rapid replacement of roller units with prism units, significantly reducing changeover time.

• Versatile Rotor Balancing: Capable of balancing rotors with small distances between bearing journals, limited only by the drive belt width.

• Variable Speed Control: Frequency inverter asynchronous electric drive with a powerful motor for infinitely variable speed control and smooth acceleration/deceleration.

• Height-Adjustable Supports: Adjustable supports to accommodate different bearing journal diameters, aiding in centering the workpiece.

• Easy Installation: Requires no special foundation and can be installed on a standard concrete floor.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• Easy to learn working skills and maintenance for any employee.

SPECIFICATIONS

Weight range of balanced rotors 0.3 - 30 kg (60 kg)

Maximum rotor diameter (above the bedding) 700 mm

Distance between centres of rotor supports 10 – 700 mm

Support type Rollers + Prisms

Transmission element for rotor rotation Belt

Minimum achievable residual specific unbalance 0.4 g*mm/kg

Rotor speed range 300 – 2000 rpm

Electric motor power 0.75 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Gijdpotu Ukaefx Aaljn

Listing

Odesa

Odesa

5,211 km

Crankshaft Balancing Machine

VTM Group9D715US

Call

Condition: new, 9D715US crankshaft balancing machine is adapted for balancing crankshafts of various designs, including crankshafts of V6, V8, V10 and V12 engines, with balancing weights on the connecting rod pins:

- Balancing of crankshafts of any design

- Shaft weight up to 300kg

- Shaft length up to 1400mm

- Drilling module for unbalance correction

The machine design allows balancing crankshaft separately, as well as crankshaft complete with flywheel and clutch, which guarantees minimum unbalance during engine operation.

MACHINE HIGHLIGHTS

• Hard-bearing supports - safe operation with high initial unbalance at low speeds.

• Roller cassettes with large diameter spherical rollers and provide the required accuracy for balancing heavy shafts.

• Replaceable antifriction prismatic V-blocks allow balancing of crankshafts with low mass or with special bearing journals.

• Narrow support stands of the machine allow balancing of crankshafts with complex configuration and with “narrow” bearing journals. The 9D715US machine has a cassette width of 27 mm, which is the best in its class.

• For balancing V-shaped crankshafts, the machine can be equipped with counterweights (variable weight) to simulate the weight of connecting rods.

• A vertical drilling module mounted on its own guides allows unbalance in the crankshaft counterweights to be corrected directly on the machine.

• The frequency converter drive provides smooth acceleration and deceleration of the electric motor and infinitely variable speed control of the rotor.

Godpjwk Ittsfx Aalsin

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• Measuring balancing system has additional necessary functions for crankshaft balancing:

- recalculates the unbalanced mass to the drilling depth, taking into account the drill diameter and the permissible drilling depth.

- It recalculates the unbalance on several correction planes, so that unbalance can be corrected in neighboring crankshaft counterweights.

SPECIFICATIONS

Weight range of balanced rotors 3 - 300 kg

Maximum rotor diameter (above the bedding) 1100 mm

Diameter of rotor support journals 20 - 140 mm

Distance between centres of rotor journals 150 – 1350 mm

Support type Rollers / V-blocks

Transmission element for rotor rotation Belt

Minimum achievable residual specific unbalance 0.4 g.mm/kg

Rotor speed range 300 – 1500 rpm

Electric motor power 2.2 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

VTM Group balancing machines will allow you to do your job well and get positive feedback and attract more customers.

Do you need a machine for a different load capacity, diameter or length?

We manufacture balancing machines for every needs.

Please contact us to get the best offer!

👇

Listing

Odesa

Odesa

5,211 km

Industrial Drive Shaft Balancing Machine

97VK1000

Call

Condition: new, total length: 6,000 mm, rotor diameter: 500 mm, The 97VK1000 balancing machine is a high-tech equipment designed for service and repair companies specializing in the maintenance of industrial drive shafts weighing up to 1000 kg.

It provides accurate and efficient balancing of cardan shafts, reducing repair time and ensuring high productivity of work processes.

The 97VK1000 balancing machine is the perfect combination of high technology, reliability and versatility, making it an essential tool for engineers and technicians involved in the maintenance and repair of industrial cardan shafts.

HIGHLIGHTS

1. Hard-Bearing Design: Designed with high precision and reliability in mind, the 97VK1000 balancing machine features a hard-bearing design to balance shafts with large initial imbalances.

2. Universal Design and Equipment: The 97VK1000 is equipped with universal equipment to balance shafts with flanges of various shapes and sizes. Special plates and adapters allow cardan lengths up to 6000 mm and flange diameters up to 500 mm.

3. Fast and Efficient Balancing Process: Thanks to the short unbalance measurement cycle, the 97VK1000 provides fast and accurate adjustment, which reduces repair time and increases the productivity of service and maintenance operations.

4. Safety and Ease of Operation: Screw jacks provide comfort and safety when working on the machine, the asynchronous variable frequency drive allows infinitely variable speed control without stopping the motor, providing optimal modes for balancing.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• Easy to learn working skills and maintenance for any employee.

Giodpfx Aajwc T Utslsn

SPECIFICATIONS

Weight range of balanced shafts 50 - 1000 kg

Maximum tube diameter 300 mm

Maximum flange diameter 500 mm

Maximum drive shaft length 6000 mm

Minimum achievable residual specific unbalance 10 g*mm/kg

Rotor rotation speed 300 – 1000 rpm

Electric motor power 11 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Do you repair industrial drive shafts?

Then we can additionally offer an Assembly-Welding Workbench for heavy shafts.

Please contact us to get the best offer!

👇

Listing

Odesa

Odesa

5,211 km

Driveshaft balancing machine

VTM GroupBVI-03-88

Call

Condition: new, DRIVESHAFT BALANCING MACHINE BVI-03-88

Balancing machine for professional repair of cardan shafts up to 200 kg.

The hard-bearing machine is adapted for heavy cardan shafts of trucks and special machinery. The high sensitivity of the supports allows also high-quality balancing of cardan shafts of passenger cars.

The machine is designed for balancing cardan shafts in the facilities of cardan repair workshops. The machine can be quickly reconfigured for balancing a large amount of single cardan shafts of various designs, as well as for the production of small batches of shafts.

.

.

.

TWO TIMES faster then your machine.

This balancing machine is majored to balance the shaft not only qualitatively, but also quickly.

If you can balance in 2-2.5 times faster, then this is your real competitive advantage.

.

..

...

HIGH PERFORMANCE ACCESSORIES

The machine is equipped with three main types of adapters:

1. Fast clamping universal adapters. It has two main advantages: The first is that due to the special design the driveshaft flange is clamped within 5 seconds. This advantage is due to the fact that the driveshaft flange does not need to be fixed with bolts.

THE SHAFT CAN BE CLAMPED 4 TIMES FASTER WITHOUT BOLTS.

The second advantage is the centering rings. The driveshaft is mounted in the adapters with centering rings that can be made on an ordinary lathe to fit most common driveshafts.

Gjdpfxsn E Skwj Aalein

2. KV Flange adapters. Used for balancing shafts with cross-tooth flanges. Applies to four flange sizes: 120, 150, 180, 205 mm. Usually used on truck driveshafts.

3. Adapter with slots. Used to mount various flanges with holes. Mounting the driveshaft is the same as on universal adapters, with the help of centering rings.

KEY FEATURES

• Balancing of 2, 3 and 4-support cardan shafts

• Shaft length up to 5200mm, weight up to 200kg

• Cardan installation in 1 minute

• Standard set of adapters - Installation of 80% of cardan shafts;

• Three ways of fixing the center bearing

• Hard-bearing type machine - safe balancing of shafts with large initial unbalance

• Machine is operated by one worker

• Sliding tailstock spindle - quick changeover, comfortable operation

• Safety bracket with clamp for quick installation

• Measurement in all planes at one time

• Calibration of the machine by the operator

• Displays imbalance in real time

• Create and print reports

SPECIFICATIONS

Maximum cardan shaft weight 200 kg

Maximum flange diameter 300 mm

Maximum length of cardan shaft 5200 mm

Number of machine supports 4

Number of simultaneously measured planes 2, 3, 4

Minimum achievable residual specific imbalance, 10 g mm/kg

Rotor speed range 1000-2500 rpm

Parameters of the supply network 380V, 3 Ph, 50Hz

Power consumption, minimum, 3 kW

Dimensions (length x width x height) 6000 х 1100 х 1450 mm

Weight 1100 kg

Listing

Odesa

Odesa

5,211 km

Dynamic Balancing Machines

VTM Group9D716

Call

Condition: new, Dynamic Hard-bearing Balancing Machines of the 9D716 series have originally been designed to meet the needs of a wide range of customers.

They are undoubtedly the best solution if you need to balance a wide range of rotor types, weights and sizes. This has led to their use in a wide range of industries.

The machines have many unique technical solutions that allow you to set up and balance complex rotors in the shortest possible time without losing the accuracy of the unbalance detection.

MACHINE HIGHLIGHTS

• The specially designed rollers use advanced patented Exact Barrel grinding technology and are mounted on precision bearings.

• The monolithic design of the supports and base eliminates vibration losses during balancing by reducing the number of "oscillating system" elements.

• Allows large initial unbalances to be measured without destroying the machine, and rotor unbalance to be corrected directly on the machine.

• The low natural resonance frequency of the supports allows the rotor to be balanced at low speeds.

• The width of the support rollers and roller block allows the installation of rotors with very short rotor bearing journals. The modular design allows rotors with unusual configurations to be mounted using spacers or tools.

• The height of the roller block is adjustable, allowing rotors with different journal diameters to be balanced and the rotor to be centred during machine set-up.

• The unique "Micro-Tuning" technology eliminates the effects of axial slippage during rotation.

• The belt drive has a patented "long stroke" design that allows any rotor to be rotated using only two drive belts.

• The frequency converter drive provides smooth acceleration and deceleration of the electric motor and infinitely variable speed control of the rotor.

MACHINE DESIGN OPTIONS

• Axial drive that uses a cardan shaft. Capable of transmitting high torque from the electric motor to the rotor. This type of drive is used for parts with high aerodynamic resistance or special design features (e.g. augers).

• Drilling module for unbalance correction of the rotor without removing it from the machine. Convenient to use to increase the productivity of the operation.

• Extended machine bed. The base of the machine can be made for any length of rotor. In our practice we have had machines for rotors of 12 metres in length.

MEASUREMENT AND CONTROL

• We make balancing easier - the main advantage of our balancing systems.

• The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result.

• The maximum sensitivity of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself.

• Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference.

• World-leading functionality and accuracy.

SPECIFICATIONS

Weight range of balanced rotors 5 - 500 kg

Maximum rotor diameter (above the bedding) 1300 mm

Diameter of rotor support journals 30 - 180 mm

Distance between centres of rotor support journals 200 – 2000 mm

Gjdpon Hwqvofx Aaloin

Support type Rollers

Transmission element for rotor rotation Belt / Cardan

Minimum achievable residual specific unbalance 0.4 g.mm/kg

Rotor speed range 300 – 1500 rpm

Electric motor power 4.0 kW

Parameters of the supply network 380V, 3 Ph, 50Hz

Listing

Odesa

Odesa

5,211 km

Turbocharger core balancing machine

VTM GroupDBST-20

Call

Condition: new, Turbocharger core balancing machine DBST-20

Low-speed turbocharger core balancing machine meets the needs of turbocharger repair workshops.

Machine is used for balancing common truck and passenger car turbos. It is multi-functional and universal, so it is suitable for many large turbochargers of special vehicles, railroad and marine turbines, and even for industrial turbochargers of gas and diesel power plants.

The DBST-20 is used for balancing common truck and car turbochargers. It is multifunctional and universal, so it is suitable for many large turbochargers of special vehicles, railway and marine turbines, and even industrial turbochargers of gas and diesel power plants.

This stand allows for the final balancing of cartridges due to the specific design features of large turbines.

The stand is used for balancing turbocharger cartridges at low speeds, as well as for checking turbocharger cartridge oil leaks.

This is a larger version of the DBST-10 model that our company has developed specifically for large turbochargers weighing up to 30 kg.

HIGHLIGHTS

High accuracy of determining the unbalance of the rotor (0.4 g ∙ mm / kg).

Reinforced torsional vibration suspension - high accuracy of vibration transmission, quality balancing results.

Mounting the cartridges on their standard surfaces (as on the engine) allows the installation of almost all turbochargers.

Wide range of accessories and adapters for installing any kind of turbos.

Includes adapters for installing turbochargers with lower oil inlet.

Oil system with oil heating allows to recreate similar conditions to the real one during balancing.

3-stage system of oil filtration allows to eliminate an unbalance directly on the machine by portable grinders.

The measuring system displays the balancing process in real time and monitors the rotor unbalance behaviour on the screen to achieve the best possible result.

Rotor adjustment and machine calibration are performed by the operator, ensuring maximum machine sensitivity at all times.

Safe turbo shaft speed allows risk-free quality running-in of assembled cartridges, which significantly increases cartridge reliability after repair.

KEY FEATURES

• High accuracy 2 plane balancing

• Truck and car turbocharger balancing

• Any turbocharger can be installed

• All type turbocharger adapters included

• Quick and easy turbo core installation

• Balancing speed up to 10 000 rpm

• Fast oil heater and temperature regulation

• 3-stage oil filtration

• Real-time unbalance measurement

• Calibration of the machine by the operator

• Industrial fanless touch screen PC control system

Giodpsn Nxcfsfx Aalon

• Creation and printing of reports on turbocharger balancing

SPECIFICATIONS

Maximum turbocharger weight 30 kg

Maximum turbocharger diameter 300 mm

Maximum turbocharger length 300 mm

Maximum rotation speed 10 000 rpm

Minimum achievable residual specific imbalance, 0,4 g mm/kg

Pneumatic system operating pressure 0,6 – 0,8 MPa

Power supply 220V, 1Ph, 50Hz

Power input 1,5 kW

Dimensions 1120 х 780 х 1350 mm

Weight 285 kg

Listing

Hessisch Lichtenau

Hessisch Lichtenau

6,811 km

Micro balance, laboratory balance, precision balance, fine balance, scale, micro balance, micro bala

METTLER TOLEDOXS3DU

Call

Condition: used, Microbalance, Laboratory Balance, Precision Balance, Analytical Balance, Scale, Micro Balance

METTLER TOLEDO Model XS3DU

S/N 1129453969

Part No. 18.11.2.1518.756-1

Year of Manufacture: 2008

Functions: Weighing, Statistics, Formulation, Density, Percentage Weighing, Piece Counting

Maximum Capacity: 3.1 g

Readability: 0.01 mg

Taring Range: 0 … 3.1 g

Maximum Capacity (Fine Range): 800 mg

Readability (Fine Range): 0.001 mg

Repeatability (at nominal load): 6 μg (3 g)

Repeatability (fine range at nominal load): 0.8 μg (0.2 g)

Linearity Deviation: 10 μg (0.5 g)

Corner Load Deviation (test load): 4 μg (1 g)

Sensitivity Deviation (test weight): 45 μg (3 g)

Temperature Drift of Sensitivity: 0.0001 %/°C

Sensitivity Stability: 0.0001 %/a

Repeatability (low load): 3 μg (0.2 g)

Repeatability, fine range (low load): 0.5 μg (0.2 g)

Giedpfx Aaowrtbxelen

Linearity Deviation: 3 μg (3 g)

Corner Load Deviation (test load): 1.2 μg

Sensitivity Deviation (test weight): 9 μg (3 g)

Minimum Sample Weight (USP): 6 mg

Minimum Sample Weight (USP) fine range: 1 mg

Minimum Sample Weight (U = 1%, k = 2): 0.6 mg

Minimum Sample Weight (U = 1%, k = 2) fine range: 0.1 mg

Stabilization Time: 6 s

Stabilization Time (fine range): 10 s

Interface Update Rate: 23 1/s

Draft Shield Diameter: 68 mm

Draft Shield Usable Height: 55 mm

Weigh Pan Diameter: 25 mm

- LCD Touchscreen

- RS232C Interface

- Printer Type RS-P42

- Tare Function

Power Supply: Primary 100 – 240 V AC, 50/60 Hz; Secondary 12 V DC, 2.5 A

Terminal/Display Unit Dimensions (L x W x H): 285 x 195 x 80 mm

Weighing Cell Dimensions (L x W x H): 288 x 128 x 114 mm

Printer Dimensions (L x W x H): 210 x 150 x 90 mm

Total Weight: approx. 7 kg

Good condition

Listing

Bydgoszcz

Bydgoszcz

6,269 km

Portable device for field balancing

CIMATSmaRT

Call

Year of construction: 2023, condition: as good as new (ex-display), The mobile field balancing machine from the experts

The statistics are indisputable: Over half of all faults and failures of machines and systems can be attributed directly or indirectly to unbalances in rotors. The SmaRT helps you to identify an unbalance simply and accurately, and to correct it with the minimum effort.

Gisdpfsmt Atdex Aalsn

With the SmaRT, rotors of almost any size and weight can be balanced quickly, costeffectively and accurately in the installed condition, and therefore without having to dismantle the machine.

The SmaRT advantages:

• Easy operation with the aid of navigation and function buttons,

• Large illuminated colour display,

• Standardised vibration measurement,

• Assessment setup to DIN ISO 10816-3,

• Simple transfer and documentation of measurement results.

Listing

Schwabach

Schwabach

6,707 km

Grinding wheel balancer

Hofmann

Call

Condition: good (used), functionality: fully functional, Manufacturer: HOFMANN

Type: NG-1

Machine No.: 922472

Gedpfxexzf E Eo Aalsin

Max. disc diameter: 320 mm

Max. loading weight: 20 kg

Listing

Monheim am Rhein

Monheim am Rhein

7,008 km

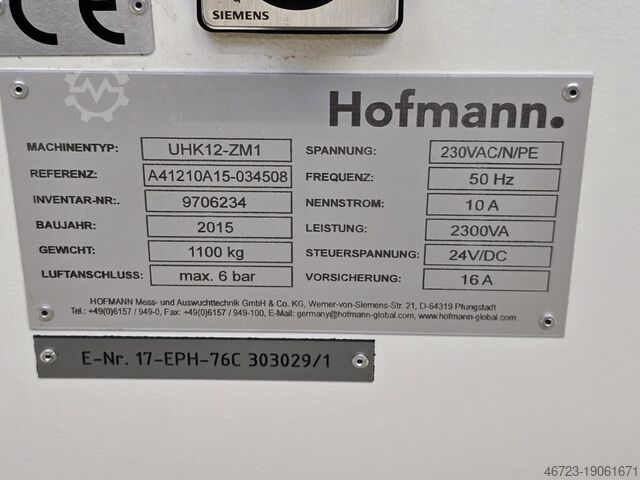

Balancing machine

HofmannUHK 12 - ZM1

Call

Condition: good (used), Year of construction: 2015, Lot consists of:

(1) CNC Crankshaft Control Balancing Machine

Giedpfxswg A Sij Aalsn

Position consists of:

(1) CNC crankshaft control balancing machine

Technical Details/Technical Details:

English:

max crankshaft length 800mm, max dia 300/200mm, max weight 50kg, bearing dia 30 - 80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH,:1.3x1x1.5m

Parts Gantry System and/or Cranes are not included in the scope.

German:

Maximum crankshaft length 800mm, maximum diameter 300/200mm, maximum weight 50kg, bearing diameter 30-80mm, balancing speed 200-650 rpm, 230V 50Hz, LxWxH: 1.3x1x1.5m

Parts gantry system and/or cranes are not included in delivery.

Listing

Krosno

Krosno

5,945 km

Industrial static balancing machine

CimatCMT30/STATIC

Call

Year of construction: 2017, condition: excellent (used), functionality: fully functional, machine/vehicle number: CMT 30/STATIC, Non-rotating industrial balancer for grinding wheels, brake discs, fans, rims, etc. Automatic balancer for a wide range of applications.

Giedpfxow Hwlwo Aaljn

Trust Seal

Dealers certified through Machineseeker

Auction

Auction ended

Sachsen

Sachsen

6,627 km

Horizontal balancing machine for rotors

HOFMANNUHK 26

Condition: ready for operation (used), Year of construction: 2004, functionality: fully functional, TECHNICAL DETAILS

Maximum balancing weight: 2,000 kg

Balancing body diameter without machining unit: 10 mm

Bed length: 3,000 mm

Swing diameter over machine bed: 2 mm

Rotor shaft via belt drive: 10 mm

Drive unit balancing speed (5 gears): Max. 80 / 160 / 290 / 470 / 630 rpm

Measurement method: force measuring

Electronics speed measurement range: 60 to 30,000 rpm

Center height measured in bed: 1,200 mm

Rollers: 2x 195 x 56 mm

Axle spacing: 205 mm

Adjustment travel: 3 mm vertical

MACHINE DETAILS

Drive power: 22 kW

Compressed air: 6 bar

Connected load: 25 kVA / 20 kW

Machine weight: approx. 5,500 kg

Machine dimensions approx. (L x W x H): 3.3 x 1.5 x 2.0 m

Control cabinet dimensions: 6 x 610 x 21 mm

Gisdpfjw T Sqmox Aalsn

EQUIPMENT

- Measuring electronics PCX

- Base frame (cast steel body)

- Mounting length between bearing supports up to approx. 3,000 mm

- Adjustment with hand ratchet via rack

- Bearing supports/swing bearing blocks: 2 pieces

Listing

Essen

Essen

7,003 km

Balancing machine

SchenckSENSiQ® RTN – 4,7 t – C3

Call

Condition: used, functionality: unexamined, machine/vehicle number: S/N: 002815GL, 8x Schenck load cells SENSiQ® RTN – 4.7 t – C3

Used, good condition – S/N: 002815GL

For sale are eight high-quality Schenck load cells of the SENSiQ® RTN type, each with a capacity of 4.7 tons and accuracy class C3.

Gijdjxyi Alopfx Aaljn

The load cells were removed from a fully operational system and are in good, used condition. They have always been handled with care and professionally dismantled.

Listing

Kerava

Kerava

6,083 km

Balancing machine

SchenckHU 9 T

Call

Condition: used, functionality: fully functional, Used Schenck Balancing Machine HU 9 T with used CAB 690 H measuring unit.

The machine comes with original foundation drawings, documentation and manuals.

The machine can be test run in Kerava.

Technical data:

- Maximum rotor weight with roller bearings: 50 000 kg

- Maximum weight for symmetrical rotor: 56 000 kg

- Load capacity per bearing pedestal: 28 000 kg

- Load capacity per T-slot pedestal: 28 000 kg

- Minimum rotor weight: 2 500 kg (1000 kg)

- Maximum diameter over machine base: 4 000 mm

Gedjw Aaugepfx Aalsin

- Machine bed length: 15 000 mm

- Adjustable roller bearing diameters: 125–270 mm , 450–900 mm

- ABB electrical drive FC: 90 kW

- 4-speed gearbox: approx.120–1400 rpm

- Pneumatic locking for end drive

- Electrically operated movable pedestals

- Accuracy: Umar 0,5gmm /kg 270 rpm 1000 gmm

Listing

Tychy

Tychy

6,145 km

Balancer

SCHENCKTBcomfort

Call

Condition: excellent (used), Year of construction: 2011, functionality: fully functional, workpiece weight (max.): 5 kg, total width: 360 mm, total length: 700 mm, Universal dynamic balancer for rotors from 10g - 5kg

Gisdsuh Svpopfx Aaljn

We make it easier for you to find: "balancer"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Balancer (819)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month