Used Carpentry for sale (171)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Siedlce

Siedlce

5,967 km

Planer-thicknesser

CORMAKPT260 230V

Call

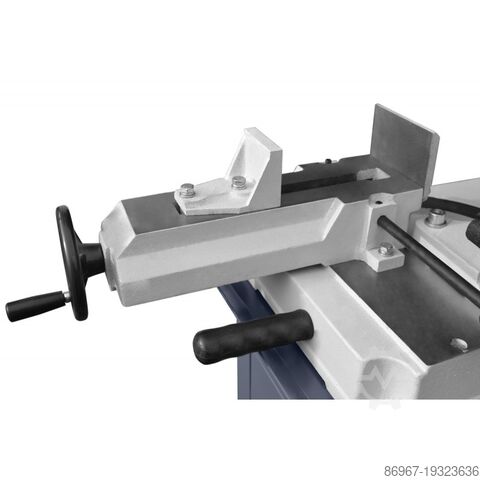

Condition: new, Year of construction: 2025, CORMAK PT260 230V Jointer-Thickness Planer – NEW VERSION

Compact and precise woodworking machine for professional and hobby use

The jointer-thickness planer is a versatile woodworking tool that allows for accurate flattening, thicknessing, and surface smoothing of wood. Ideal for furniture making, carpentry, and material preparation, it performs jointing, planing, edge processing, board production, and surface preparation for gluing. Featuring a durable cast iron table, three-blade cutterhead, powerful motor, and precise adjustment controls, it ensures high performance with ease of use.

Applications

The CORMAK PT260 230V jointer-thickness planer is ideal for:

Woodworkers and craftsmen producing furniture elements, moldings, and wood structures

Renovation and construction workshops processing raw and laminated timber

Hobby workshops seeking a reliable, high-precision planer for home use

Schools and training centers providing hands-on woodworking education on professional equipment

Standard Equipment

Ø75 mm cutterhead with 3 knives (250 × 30 × 3 mm)

Jointer table: 1100 × 250 mm

Cpsdpfx Afow H R Aiepsu

Thickness planer table: 600 × 248 mm

Adjustable aluminum fence: 700 × 150 mm (tilting 90–45°)

Anti-vibration rubber feet

Dust port Ø100 mm

Operating manual (Polish and English)

CE Declaration of Conformity

Optional Accessories

Mortising and drilling attachment

Chip and dust extraction unit

Knife setting jig

Roller support stands

Key Features

✅ Durable cast-iron construction

✅ Compact design suitable for small workshops

✅ Smooth and accurate planing and jointing

✅ Quick adjustments for thickness and depth

✅ Efficient chip removal via 100 mm extraction port

Technical Specifications

Parameter Value

Cutterhead diameter 75 mm

Cutterhead speed 4000 rpm

Number of knives 3

Knife dimensions 250 × 30 × 3 mm

Jointer table size 1100 × 250 mm

Thickness planer table size 600 × 248 mm

Max. jointing width 250 mm

Max. jointing depth 5 mm

Max. thicknessing depth 2.5 mm

Max. thicknessing cutting depth 3 mm

Max. workpiece height for thicknessing 180 mm

Thicknessing feed speed 6 m/min

Fence dimensions 700 × 150 mm

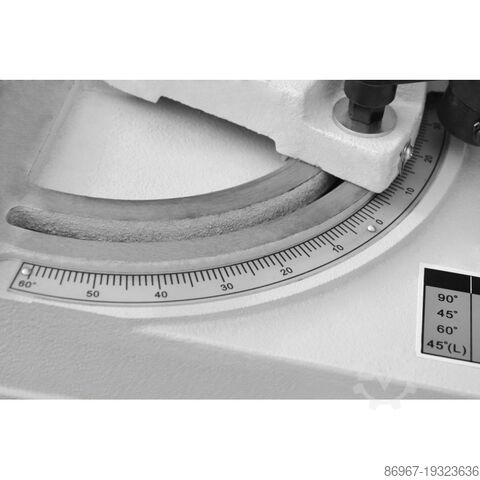

Fence tilt angle 90° – 45°

Dust port diameter Ø100 mm

Overall dimensions (L × W) 1100 × 250 mm

Machine weight 170 kg

Motor power S1: 2.0 kW / S6: 2.6 kW

Power supply 230 V

CE certification Yes

Listing

Siedlce

Siedlce

5,967 km

Cyclone dust extractor

CORMAKDC2200

Call

Condition: new, functionality: fully functional, Year of construction: 2025, CORMAK DC2200 Model

The CORMAK DC2200 is a powerful and robust cyclone dust extractor, designed to efficiently purify the air in woodworking shops, furniture factories, and metalworking facilities. Thanks to its cyclone separator, high-performance radial fan, and modern filtration system, the machine ensures effective particle separation and long-term high efficiency.

Main Advantages of the CORMAK DC2200

High extraction capacity – up to 2800 m³/h – effective removal of dust and shavings from multiple workstations simultaneously

Cyclone separator – separates larger particles before the filter, extending its service life

Powerful 2.2 kW (2200 W / 50 Hz) motor – stable and reliable continuous operation

Large 151-liter metal container – convenient and safe waste collection

Filtration area of 4.8 m² – ensures high efficiency in capturing fine dust particles

Compact, mobile design – sturdy frame with transport wheels for easy movement

Quiet operation – optimized fan design reduces noise without sacrificing performance

Design and Technology

The CORMAK DC2200 is equipped with a 365 mm radial fan, generating a maximum static pressure of 2220 Pa. This allows efficient air suction through long ducting systems and multiple workstations. The extractor offers three suction inlets (3 × Ø100 mm) and one main inlet (Ø200 mm) for flexible setup according to the production area layout.

The cyclone separation system effectively removes heavier particles at the inlet, directing only pre-cleaned air to the container. The cylindrical filter (Ø370 × 612 mm) ensures consistent airflow even during intensive operation.

Performance and Ergonomics

The DC2200 extractor is designed for daily use in small and medium-sized workshops. The 151-liter container (Ø620 × 570 mm) provides long working cycles without frequent emptying. With its compact dimensions (1320 × 900 × 1840 mm) and lightweight design (136 kg net), the unit fits easily into any workspace.

Applications

The CORMAK DC2200 is ideal for use in:

Carpentry and furniture workshops

Sawmills and wood-processing facilities

Model-making and metalworking shops

Production of composite and MDF components

Standard Equipment

Cyclone separator

Cylindrical filter with large filtration surface

151 L metal container for dust and shavings

Transport wheels

Cpsdpfxoxrdhaj Afpou

Suction inlets: Ø200 mm and 3 × Ø100 mm

Technical Specifications

Parameter Specification

Motor power 2.2 kW / 50 Hz

Airflow (without filter) 2800 m³/h

Max. static pressure 2220 Pa

Fan diameter 365 mm

Inlet diameter 1 × Ø200 mm / 3 × Ø100 mm

Container volume 151 L

Container dimensions Ø620 × 570 mm

Filter surface area 4.8 m²

Filter dimensions Ø370 × 612 mm

Overall dimensions (L × W × H) 1320 × 900 × 1840 mm

Weight (net / gross) 136 / 170 kg

Listing

Siedlce

Siedlce

5,967 km

Table for sanding wood and metal

CORMAKDT1000M

Call

Condition: new, Year of construction: 2025, Professional Table for Sanding Wood and Metal. A filtration device that is suitable for use wherever sanding operations are performed. RADIANT FAN, HIGHER VACUUM PRESSURE.

Our equipment is installed in carpentry workshops, furniture workshops, and industrial paint shops. Designed for sanding wood and metal.

The table is equipped with an independent dual filtration system, ensuring precise air purification from all contaminants!

A special high-efficiency radial fan guarantees long operation without the need to change the filtration materials.

The five-segment work table makes it easier to position workpieces and clean the filters.

Quick and easy filter replacement.

The table is equipped with pins and clamps for mounting workpieces.

Ventilation system at the bottom and on the side of the table.

Filter resistant to high temperatures, but not fireproof.

Segregation of "large" and "small" sanding waste.

Spacious metal drawer.

High vacuum pressure (dust filtration efficiency > 99.9%).

Technical Specifications:

Work surface dimensions: 1000 x 550 mm

Working height: 850 mm

Airflow capacity: 4000 m³/h

Cedpfx Aev R Tihsfpspu

Filter size: 2 x (395 x 495 x 24 mm)

Motor power (S1): 1.0 kW

Voltage: 230V

Weight: 70 kg

Dimensions: 1050 x 600 x 850 mm

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Siedlce

Siedlce

5,967 km

Planer and Thicknesser

CORMAKPT310ET

Call

Condition: new, Year of construction: 2025, The CORMAK PT310ET planer–thicknesser is an advanced woodworking machine that combines the functionality of a jointer and a thickness planer in one robust construction. It stands out with exceptional stability, high working power, and features that increase precision and operator comfort, such as additional feed rollers integrated into the thicknessing table.

Key Advantages

S6 motor power: 2.8 kW (S1: 2.2 kW) – one of the most powerful in its class, ensuring consistent performance even under heavy loads.

Stable 180 kg construction – rigid cast-iron tables and additional rubber-coated feet minimize vibrations and increase precision.

Quick mode switching – fast change from jointer to thicknesser by lifting the tables and repositioning the chip-extraction hood.

Smooth and quiet operation – low noise emission and accurate material feed ensure operator comfort and safety.

Efficient extraction system – Ø120 mm outlet allows effective chip removal, especially during intensive use.

Unique Benefit: Feed Rollers in the Thicknesser – specially designed auxiliary roller extensions integrated into the thicknessing table support the machining of long and heavy workpieces, making feeding and collecting easier while improving surface finish quality.

Applications

Carpentry and furniture workshops – for daily, efficient machining of solid wood and laminated boards.

Cpodpfx Aoxy Hy Uofpou

Production of structural components – ideal for flattening and calibrating construction elements, stairs, frames, and mouldings.

Technical schools – for training in professional woodworking using high-quality industrial equipment.

Standard Equipment

Three HSS knives, 310 × 25 × 3 mm

Cutterhead guard

Cast-iron jointer tables

Ø120 mm dust-extraction outlet

Feed switch and emergency STOP switch

Operating manual (DTR)

CE declaration of conformity

Technical Specifications

Cutterhead diameter: 75 mm

Cutterhead speed: 5500 rpm

Dust port diameter: 100 mm

Fence tilt angle: 90–45°

Number of knives / dimensions: 3 / 310 × 25 × 3 mm

Maximum jointer width: 310 mm

Maximum thicknesser width: 308 mm

Planing height range: 5–225 mm

Maximum depth of cut (thicknesser): 2.5 mm

Maximum depth of cut (jointer): 4 mm

Thicknesser feed speed: 6 m/min

Jointer table dimensions (L × W): 1300 × 310 mm

Gross weight: 180 kg

Motor speed: 2800 rpm

Motor power: S1: 2.2 kW / S6: 2.8 kW

Power supply: 400 V, 5-pin socket, 16 A

Manual (DTR): Polish/ English

CE declaration: yes

Listing

Siedlce

Siedlce

5,967 km

Sliding Table Saw

CORMAKMJ45-KB4 (3200)

Call

Condition: new, Year of construction: 2025, functionality: fully functional, A sliding table saw for working with high density boards, MDF boards, ABS and PVC panels, solid wood and other wood-based materials of similar structure and hardness. The saw is designed for small and medium carpentry work.

Strong, professional sliding table saw with a movable table on bars and a separately powered scoring.

Saw tilts in the 90–45 degrees range

Solid, durable design ensures stability and work safety

Controllable speed adjustment

Technical data

Table dimensions 970×550 mm

Sliding table length 3200 mm

Cedotz Smiepfx Afpepu

Cutting width by the fence 1200 mm

Transverse cutting by the transverse cutting guide 3100 mm

Saw tilt 0°–45°

Saw diameter Ø350 mm

Saw hole diameter Ø30 mm

Saw blade height 0–87 mm

Saw blade 350 max height 105 mm

Saw blade height at 45° angle 0–60 mm

Saw blade 350 max height at 45° angle 73 mm

Main saw spindle speed 4000 / 6000 rpm

Scoring saw diameter Ø125 mm

Scoring saw hole diameter Ø20 mm

Scoring speed 8000 rpm

Main motor power 5.5 kW

Scoring motor power 0.75 kW

Intake connector under table diameter 100 mm

Intake connector diameter in the saw guard 80 mm

Machine weight 680 kg

Available equipment

Cutting saw

Scoring

Transverse cut fence

Longitudinal fence

Modern - ergonomic saw guard

Worktop extension

Fence for mitre cutting

Saw blade tilt gauge indicator

User manual

EC declaration of conformity

Listing

Siedlce

Siedlce

5,967 km

Sliding Table Saw

CORMAKMJ45-KB-4 (2000)

Call

Condition: new, Year of construction: 2025, A professional sliding table saw for working with high density boards, MDF boards, ABS and PVC panels, solid wood and other wood-based materials of similar structure and hardness. The saw is designed for small and medium carpentry work.

Cpjdpfx Afstz Sm Aepeu

Machine description

Strong, solid and compact design ensures convenient and and failure-free operation

Sliding table saw mounted on a spindle tilting in relation to the worktable capability

Steel, welded body with a permanent cast iron table and a movable table made of strengthened aluminium – the table of this machine is very durable and does not deform

Technical parameters

Cutting length 2000 mm

Cutting width 1200 mm

Saw tilt 0–45°

Cutting height at 90° 80 mm

Cutting height at 45° 56 mm

Maximum saw dimension 315 mm

Maximum scoring dimension 120 mm

Main saw speed 4000/6000 rpm

Scoring speed 8000 rpm

S1 continuous work motor power 5.5 kW

S1 continuous work scoring motor power 0.75 kW

Weight 460 kg

Listing

Siedlce

Siedlce

5,967 km

DCV5200E+ Industrial extractor

CORMAKDCV5200E+

Call

Condition: new, Year of construction: 2025, The CORMAK DCV5200E+ extractor is an efficient device for removing dust and wood chips, ideal for the carpentry industry. It has a 3 kW engine, a capacity of 5200 m³/h and 18 polyester filters that retain particles down to 5 microns. The compact design, metal rotor and the ability to connect to several machines ensure efficiency and cleanliness of work.

Extractor equipped with an automatic shaking system!

Technical parameters

CONTINUOUS MOTOR POWER S1

3 kW / 400 V, 50 Hz

SPEED

3000 rpm

SUCTION EFFICIENCY

5200 m3/h

Cpedowlr Azepfx Afpju

SUCTION PIPE DIAMETER

200 mm

SUMP SPEED

30 m/s

FILTER SURFACE

10 m2

FILTER MATERIAL

Polyester, 5 microns

NUMBER OF FILTERS

18

DIMENSIONS

2441 x 940 x 2270 mm

WEIGHT

260 kg

Listing

Siedlce

Siedlce

5,967 km

Two disk sander

CORMAKM200S

Call

Condition: new, Year of construction: 2025, The Cormak M200S sander is a professional tool with high performance and precision. Equipped with a powerful drive motor, it provides fast and efficient grinding of various materials. The rotor design based on ball bearings ensures motor reliability and quiet operation. Plastic guards protect against sparks. This is a versatile tool that is easy to use thanks to the speed control and ergonomic handle. Ideal for professionals and hobbyists.

Features of the M200S disc grinder

The Cormak M200S grinder is a professional grinding tool that offers an excellent combination of high performance, precision and durability. Thanks to the rotor design based on ball bearings, this grinder guarantees motor reliability and quiet operation, which is important for both intensive use in the workshop and in domestic applications.

The powerful drive motor of the Cormak M200S sander is equipped with high torque, which translates into efficient material removal and a fast surface finish. The number of revolutions provides the optimum sanding speed for a variety of materials. The motor power of 0.9 kW allows efficient material removal and rapid achievement of the desired results. Designed for use with 400 volts, ensuring stable power supply and efficient operation. Regardless of the type of material, be it wood, metal or plastic, this sander will meet all requirements.

Equipped with a 200x32 mm fi sanding disc, it enables larger surfaces to be sanded efficiently. An important aspect that contributes to work safety is the Cormak M200S sander's plastic guards. As well as providing protection from sparks, the guards are lightweight yet robust, making them easy to manoeuvre and reducing operator fatigue. In addition, the intuitive control panel provides convenience and ease of use.

Cpodjvlkttjpfx Afpou

If you are looking for a professional sanding tool that offers reliability, high performance and precision, the Cormak M200S sander is an excellent choice. Its robust construction, powerful motor, protective guards and ability to connect a dust extraction system make it an indispensable tool in the workshop, carpentry shop or during renovation work. Check the specifications and compare prices to find the best deal for your needs.

Technical specifications of the M200S disc sander

SIZING DIAGRAM 200 x 32 mm

disc or grinding wheel opening 32 mm

DISC GRANULATION K 36 / K 60

RPM NUMBER 2850 rpm

MOTOR POWER S1 0,9 kW

MOTOR POWER S6 1,5 kW

VOLTAGE 400 V

DIMENSIONS 520x300x1130 mm

WEIGHT 26 kg

Listing

Siedlce

Siedlce

5,967 km

Dust and chip extraction

CORMAKDCV4500 Viber

Call

Condition: new, Year of construction: 2026, The CORMAK extraction units of the DCV series have been developed for the filtration of primarily very fine-grained dust. It is designed to clean itself in an automatic cycle without any effort on your part. Our technology department has placed great emphasis on creating a motorised shaking system in which the entire filter cleaning cycle takes place automatically in a closed system.

Strengths of the DCV dust extraction units

Robust solid construction for quiet and vibration-free operation of the dust extractor

Very high tightness of the entire extraction system, guaranteeing best air quality inside the plant and no heat loss during the heating period

Powerful and quiet radial fan for high vacuum performance

Possibility to build a ceiling system and feed several machines working simultaneously with the DCV extraction units

Trouble-free automatic filter shaking system

Mobile chassis to facilitate trouble-free movement of the extraction units throughout the plant

Waste containers designed to maintain 99.99% containment and equipped with a mobile trolley system

Control cabinet with the possibility of precise tracking of filter contamination status or activation / deactivation of the unit

The polyester filter traps dust with a diameter of up to 5 microns, for the filtration of smaller particles a filter such as HEPA must be used

It is forbidden to use this extraction in explosive atmospheres.

The extraction is used for working in the carpentry industry with sawdust, shavings, dust (it is not suitable for working with wet raw material e.g. wet sawdust)

Before activating the extraction, the lower beam has to be dismantled in order to have free access to the chip container

Technical specifications

CONTINUOUS DUTY MOTOR POWER S1

3.0 kW

RPM

3000 rpm

EXTRACTION CAPACITY

4500 m3

DIAMETER OF THE SUCTION NOZZLE

200 mm

SUCTION VELOCITY

28-32 m/s

FILTER AREA

6 m2

FILTER MATERIAL

Cjdpfxeuc Unqj Afpepu

Polyester, 5 microns

NUMBER OF FILTERS

18

DIMENSIONS

752 x 1502 x 2200 mm

WEIGHT

200 kg

Listing

Siedlce

Siedlce

5,967 km

Sliding Table Saw

CORMAKPS12E-1600

Call

Condition: new, Year of construction: 2025, The PS12E-1600 format saw is a professional carpentry tool with a versatile specification and excellent functionality. This circular saw is designed to meet the requirements of both professional craftsmen and amateur woodworkers.

Main features of the PS12E-1600 wood panel saw with undercutter:

Two cutting discs: The saw is equipped with two cutting discs - a main disc and an undercutting disc

Safety front of the machine: On the front of the saw you will find a safety switch, a blade height adjustment knob up to 100mm and a blade tilt lock

Cutting angle adjustment: There is a knob on the side of the machine that allows the cutting angle of the cutting disc to be adjusted up to 45°

Extraction connection hole: The saw is designed to be connected to an extraction port for effective dust and chip removal, which is important for keeping the workplace clean.

Large bearing-mounted format table: one of the main features of this saw is the large bearing-mounted format table with support, which enables precise cutting of large-format boards and materials.

Guide with angle graduation: The guide is equipped with an angle graduation, which allows any cutting angle to be set precisely.

Side guide with accurate graduation: For serial cuts of the same length, the machine has been equipped with a side guide with accurate graduation to ensure precise and repeatable cuts.

Replacement of the cutting disc: The disc is changed quickly and efficiently by removing the metal top and unscrewing the disc.

Cuts at angles of up to 45°: The saw has the ability to cut at angles of up to 45°, which is useful for complex carpentry projects.

Maximum guide length 1600mm: The long guide allows you to cut boards and format boards up to 1600 mm long.

Helpful extras: The upper table top is equipped with a cutting length scale and a gauge with an additional measure for measuring and cutting materials with a large surface area.

Control panel: The machine's control panel is located on the bottom of the saw and includes an emergency stop, a knob for angle cuts (up to 45°) and a blade height adjustment knob with locking mechanism.

3.8 kW motor: The discs are driven by a powerful 3.8 kW motor at 400V for efficient and effective cutting.

Application of the saw, wood format saw:

The PS12E-1600 format saw is a tool that combines versatility and precision for a wide variety of cuts and carpentry projects. Its advantages, such as a large work surface, adjustable cutting angle, and the ability to connect an extraction device, make it an excellent choice for professional woodworkers and craftsmen.

Technical data:

Length of format table [mm] 1600

Cutting width right side [mm] 1260

Swing of saw blade [°] 45

Cutting height at 45° [mm] 80

Cutting height when fitted with circular saw blade 315 90° [mm] 100

Cutting height with saw blade set to 300 90° [mm] 95

Maximum dimension of saw blade [mm] 315 x 30

Maximum dimension of undercut [mm] 100 x 20

RPM of main saw [U/min] 4500

Rotation of the undercut saw [U/min] 5800

Motor power [S1/S6] 3.8 kW / 6.1 hp

Power supply 3 phases, 400 V

Cedpfxsvuf Uqj Afpjpu

Weight [kg] 275

Listing

Siedlce

Siedlce

5,967 km

High-vacuum centrifugal fan

CORMAKFAN11

Call

Condition: new, Year of construction: 2025, Thermal winding protection against overload. The extraction design has been enhanced with additional anti-vibration feet in the base to guarantee stable and vibration-free operation of the unit. The most powerful radial fan FAN11 achieves an output of up to 15445 m3/h.

The Radial Ventilator can transport air chips sawdust dust and other substances such as smoke or harmless gases.

It is widely used for ventilation in industrial lumber companies, carpentry, mining, large buildings, hotels, restaurants, etc.

Thanks to its design and reinforced balanced impeller with many blades, it guarantees stable, quiet and vibration-free operation .

The high efficiency of the fan due to the suitable shape of the blades significantly reduces the consumption of electricity without changing its high performance.

Cjdpfxevugfwj Afpjpu

APPLICATION OF THE FAN

production of various types of materials

transport to dehumidifiers and drying systems.

carpentry - transport of chips, sawdust, dust

agricultural industry - transport of fine granulates,

manufacturing - transport of polystyrene granulates, etc.

automotive industry - transport of dusty air, impurities

Listing

Siedlce

Siedlce

5,967 km

Radial Fan-Blower

CORMAKFAN1500

Call

Condition: new, Year of construction: 2025, The fan, created on the basis of a radial impeller blade system, is designed for handling waste generated during wood processing. The high vacuum and high motor power ensure a constant underpressure.

Thanks to the many years of experience of our CORMAK team, FAN series radial fans were created. The design of the new technological line has allowed us to create a LineWind metal turbine system. This is the most important feature of radial fans, allowing with increased vacuum power to draw off various types of pollutions to a special blade system that has been profiled at the right angle. The radial fan was created for use in the carpentry, furniture, car, agricultural and manufacturing industries.

Advantages:

radial fans are using for:

- transport of shavings, sawdust, small granules

- dusty air

- local exhaust

- drying systems

- air dryers

multi-blade, balanced, low noise and high efficiency, metal rotor

winding overload thermal protection (thermal sensor)

anti-vibration, stabilising feet

safety swith conformant withthe N-EN ISO 12100 and PN-EN ISO 13850 norms

it is also includes flexible and durable gaskets in the most vital locations

failure-free operation confirmed by users of our machines working with them every day

CAPACITY MAX. 3000 m3/h

INLET DIAMETER 150 mm

OUTLET DIAMETER 150 mm

ROTATIONS 2850 obr/min

Cedpfx Afovuggbspspu

DIMENSIONS 575 x 510 x 500 mm

MOTOR POWER/VOLTAGE 1,5 kW/400 V

WEIGHT 32,5 kg

Listing

Siedlce

Siedlce

5,967 km

High-vacuum centrifugal fan

CORMAKFAN5,5

Call

Condition: new, Year of construction: 2025, The most powerful centrifugal fan, the FAN5.5, achieves a capacity of up to 7419 m3/h. The design of the new technology line has enabled us to develop the LineWind metal turbine system. This is the most important feature of the radial fans, enabling them to extract all sorts of pollutants with increased vacuum power, thanks to a special blade system that has been profiled at an appropriate angle.

The Radial Ventilator can transport air chips sawdust dust and other substances such as smoke or harmless gases.

Thanks to its construction and reinforced balanced impeller with many blades, it guarantees stable, quiet and vibration-free operation.

The high efficiency of the fan due to the suitable shape of the blades significantly reduces the consumption of electricity without changing its high performance.

APPLICATION OF THE FAN

production of various types of materials

transport to dehumidifiers and drying systems.

carpentry - transport of shavings, sawdust, dust

agricultural industry - transport of fine granulates,

manufacturing - transport of polystyrene granulates, etc.

automotive industry - transport of dusty air, impurities

Codpfjvugh Ejx Afpepu

Technical parameters:

MAX. AIR CAPACITY max. 7419 m3/h

inlet diameter 300 mm

discharge diameter 250 mm

PRESSURE 2014 - 1320 Pa

DIMENSIONS 750x750x830 mm

MOTOR POWER / VOLTAGE 5.5kW

WEIGHT 110kg

Listing

Siedlce

Siedlce

5,967 km

Planer-thicknesser with cutter block

CORMAKPT310ECO

Call

Condition: new, Year of construction: 2025, Thickness and Surface Planer CORMAK PT310ECO with Cutter Block – Precision Machining and Work Efficiency

The CORMAK PT310ECO is a modern planer‑thicknesser engineered for high-quality finish, reliability, and low noise levels. Thanks to its cutter block, it is an advanced woodworking machine combining jointing and thickness functionality in a single robust structure. The stable build and powerful motor make it a versatile solution for professional woodworking—ideal for both carpentry shops and artisan workshops.

Key Machine Advantages

Cutter-block shaft – three HSS knives 310 × 25 × 3 mm ensure long service life, precise planing, and reduced noise.

Massive work tables – cast iron construction minimizes vibration and ensures stable material feed.

High power – motor rated at 2.2 kW (S1) / 2.6 kW (S6) provides consistent performance even under heavy loads.

Large working area – 310 mm width and up to 180 mm thickness capacity accommodate various workpieces.

Efficient chip extraction – Ø100 mm port enables seamless connection to a dust‑extraction system.

Construction and Technology

The PT310ECO is equipped with a 75 mm diameter cutter block that ensures smooth operation and superior durability compared to conventional knives. The planer/thicknesser features cast‑iron tables sized 1290 × 310 mm (surface planer) and 540 × 310 mm (thicknesser), both highly wear‑resistant. Additionally, the machine offers fence angle adjustment from 90° to 45°, enabling precise angled milling.

Precision and Performance

Maximum planing depth

Jointing mode: 3 mm

Thicknessing mode: 4 mm

Cutter-block rotational speed: 5,500 rpm

Stable structure enables finishes ready for gluing, coating, or further processing.

A reliable thicknesser for both serial production and smaller‑scale projects.

Applications

Ideal for:

Cedpew Ab Twjfx Afpjpu

Professional carpentry and furniture workshops

Prototyping labs and training centers

Maintenance departments in industrial plants

Technical schools and vocational institutions

Standard Equipment

Three‑knife cutter block

Cast‑iron work tables

Cutter head guard

Ø100 mm chip extraction port

Feed‑in switch and safety shutdown

Optional Equipment

Mobile trolley for the machine

Chip‑extraction unit

Technical Data

Specification Value

Surface‑planing table size 1,290 × 310 mm

Thicknessing table size 540 × 310 mm

Cutter-block diameter 75 mm

Cutter-block speed 5,500 rpm

Number/dimensions of knives 3 knives / 310 × 25 × 2.5 mm

Fence angle adjustment 90°–45°

Chip outlet diameter 100 mm

Max. thicknessing height 180 mm

Max. cut depth: planing/thickness 3 mm / 4 mm

Motor power (S1/S6) 2.2 kW / 2.6 kW

Max. workpiece width 310 mm

Gross weight 200 kg

Listing

Siedlce

Siedlce

5,967 km

Hinge Drilling Machine

CORMAKBH40M

Call

Condition: new, Year of construction: 2025, functionality: fully functional, CORMAK BH40M Hinge Drilling Machine – Precise Machining of Furniture Fittings

The CORMAK BH40M hinge drilling machine is a compact, efficient, and easy-to-use horizontal wood drilling machine designed for precise drilling of holes for furniture hinges. Ideal for carpentry and furniture manufacturing, the machine offers consistent drilling and stable tool guidance. Thanks to its intuitive design and robust components, the BH40M ensures high-quality work while maintaining ease of operation.

Main Advantages of the Machine Without a Compressed Air System:

Cpjdpfx Ajw Hbwqefpsu

Precise drilling for furniture hinges – an adjustable depth stop allows for drilling with full parameter control, minimizing the risk of material damage.

Compact and stable construction – a rigid base with a large work table (790 x 390 mm) ensures comfort and safety.

Compressed air-free – the lack of a pneumatic system translates into reliability and low operating and maintenance costs. A 0.75 kW motor – the head drive provides sufficient torque for working with Blum hinges and other hardware systems.

Three working spindles – allow for simultaneous drilling of holes for the main hinge and side guides.

Design and Technology

The CORMAK BH40M model is designed with ease of use and durability in mind. A mechanical working head travel of 110 mm and manual control ensure full control over the work cycle. The 10 mm tool shank diameter allows for the use of standard hardware drills. Compact overall dimensions (800 x 630 x 780 mm) and a weight of 45 kg make this furniture hardware drill ideal for field assembly work. Precision and Efficiency

Thanks to the optimally selected spindle speed (2800 rpm) and the ability to manually adjust settings, the operator can quickly and accurately drill holes for any standard hinge type. Adjustable drilling depth (up to 20 mm) allows for easy adaptation to various front thicknesses and hinge types. Stable workpiece clamping and parameter control minimize assembly errors and increase the efficiency of the entire process.

The CORMAK BH40M hinge drilling machine is suitable for:

kitchen, bathroom, and office furniture production,

carpentry workshops and maintenance departments,

service companies specializing in hardware installation,

woodworking schools and training centers.

Standard Equipment

Three-spindle drilling head for hinges,

mechanical guide travel (110 mm),

adjustable depth stop,

work table 790 x 390 mm,

0.75 kW (230 V) motor,

manual control and workpiece clamping.

Optional Equipment

drill bits for Blum hinges and other systems,

positioning templates for various types of fittings,

sets of mounting plates and side stops.

Technical Data

Table Dimensions 790 x 390 mm

Guide Travel 110 mm

Space Between Spindle and Table 155 mm

Tool Shank Diameter 10 mm

Number of Spindles 3

Max. Drilling depth: 20 mm

Speed: 2800 rpm

Workpiece clamping: manual

Manual control

Motor: 0.75 kW

Power supply: 230 V

Overall dimensions: 800 x 630 x 780 mm

Weight: 45 kg

Listing

Siedlce

Siedlce

5,967 km

Planer-thicknesser with spiral cutter bl

CORMAKPT310ECO z wałem spiralnym

Call

Condition: new, Year of construction: 2025, CORMAK PT310ECO Thickness and Surface Planer with Spiral Cutter Block – Precision and Work Efficiency

The CORMAK PT310ECO is a modern planer-thicknesser engineered for high finish quality, reliability, and low noise levels. Thanks to its spiral cutter block with 30 replaceable carbide inserts, the machine delivers exceptionally smooth surfaces with significantly reduced vibration and noise. Its stable construction and powerful motor make it a versatile solution for professional woodworking—both in carpentry shops and in artisan workshops.

Key Advantages

Spiral cutter block – 30 inserts (310 × 25 × 3 mm) provide long tool life, precise planing, and reduced noise levels.

Massive cast iron work tables – absorb vibrations and ensure stable material feed.

High power output – 2.2 kW motor (S1) / 2.6 kW (S6) ensures consistent performance during demanding operations.

Large working area – 310 mm planing width and 180 mm height capacity for various workpieces.

Effective chip extraction – Ø100 mm extraction port allows easy connection to dust collection systems.

Construction and Technology

The PT310ECO is equipped with a spiral cutter block of 75 mm diameter, ensuring smooth operation and significantly longer durability than traditional knives. Each insert can be rotated four times, greatly reducing maintenance and operating costs. The planer-thicknesser features wear-resistant cast iron tables: 1290 × 310 mm (planer) and 540 × 310 mm (thicknesser). The adjustable fence angle between 90° and 45° allows for accurate guiding of materials even at an angle.

Precision and Performance

Maximum cutting depth:

Planing mode: 3 mm

Thicknessing mode: 4 mm

Cutter block rotation speed: 5,500 rpm

The machine’s rigid frame enables surfaces that are ready for gluing, lacquering, or further processing.

A reliable thickness planer for both mass production and small batch work.

Applications

The PT310ECO is the ideal solution for:

Professional carpentry and furniture workshops

Prototyping labs and training centers

Industrial maintenance departments

Technical schools and trade colleges

Standard Equipment

Spiral cutter block with 30 inserts

Cast iron work tables

Cutter head guard

Ø100 mm dust extraction outlet

Feed switch and emergency stop switch

Optional Equipment

Mobile base

Dust extractor

Technical Specifications

Specification Value

Planer table dimensions 1290 × 310 mm

Thicknessing table dimensions 540 × 310 mm

Spiral cutter block diameter 75 mm

Cutter block speed 5,500 rpm

Cutting inserts 310 × 25 × 2.5 mm

Fence tilt angle 90°–45°

Chip extraction outlet Ø100 mm

Maximum thicknessing height 180 mm

Max. cutting depth 3 mm (planing) / 4 mm (thicknessing)

Motor power (S1 / S6) 2.2 kW / 2.6 kW

Cpsdpfxjw Ab Afo Afpsu

Maximum workpiece width 310 mm

Weight (gross) 200 kg

Listing

Siedlce

Siedlce

5,967 km

Hinge Drilling Machine

CORMAKBBM40MAN

Call

Condition: new, functionality: fully functional, Year of construction: 2025, CORMAK BBM40MAN Hinge Boring Machine – Precision Machining for Furniture Fittings

Cedpfsxzdicex Afpepu

The CORMAK BBM40MAN hinge boring machine is a compact, efficient, and easy-to-use woodworking drill designed for precise drilling of holes for furniture hinges. The machine performs exceptionally well in furniture production, offering repeatable drilling accuracy and stable tool guidance. Thanks to its intuitive design and robust components, the BBM40MAN ensures high-quality performance while remaining simple to operate.

Key Advantages

Precise drilling for furniture hinges – The adjustable depth stop located at the rear of the machine allows drilling with full parameter control, minimizing the risk of material damage.

Compact and stable construction – A rigid base with a large worktable (350 × 300 mm) provides comfort and safety during operation.

Powerful 1.1 kW motor – A uniquely strong motor compared with competing machines, providing the necessary torque to work with Blum-type hinges and other hardware systems.

Three working spindles – Enable simultaneous drilling of the main hinge cup hole and the side pilot holes.

Construction and Technology

The CORMAK BBM40MAN hinge boring machine is designed for simplicity, durability, and ease of use. A mechanical feed of the working head with a 110 mm range and manual control ensures full control of the working cycle. The 10 mm tool shank diameter allows the use of standard hinge-boring bits. Compact overall dimensions (370 × 500 × 600 mm) and a weight of 21.5 kg make this hinge boring machine ideal also for on-site assembly work.

Precision and Work Efficiency

With an optimally selected spindle speed (3000 rpm) and the ability to manually adjust the settings, the operator can quickly and accurately drill holes for any standard hinge type. Adjustable drilling depth allows easy adaptation to different front thicknesses and hinge systems. Stable workpiece clamping and full parameter control minimize assembly errors and increase overall process efficiency.

Applications

The CORMAK BBM40MAN hinge boring machine is used in:

production of kitchen, bathroom, and office furniture,

carpentry workshops and maintenance departments,

service companies specializing in hardware installation,

woodworking schools and training centers.

Standard Equipment

3-spindle hinge boring head,

mechanical fence feed (110 mm),

adjustable depth stop,

350 × 300 mm worktable,

powerful 1.1 kW motor (230 V),

manual control and workpiece clamping,

35 mm cutter + two 2 mm bits for BLUM hinges.

Technical Specifications

Specification Value

Table dimensions 350 × 300 mm

Fence feed 110 mm

Distance between spindle and table 130 mm

Tool shank diameter 10 mm

Number of spindles 3

Max. drilling depth 10 mm

Speed 2800 rpm

Workpiece clamping manual

Control manual

Motor 1.1 kW

Power supply 230 V

Overall dimensions 370 × 500 × 600 mm

Weight 21.5 kg

Listing

Siedlce

Siedlce

5,967 km

CNC Milling router for wood C2030

CORMAKC2030 PREMIUM 2100x3100mm

Call

Condition: new, Year of construction: 2025, PREMIUM MODELS ARE CHARACTERIZED BY HIGH RIGIDITY AND MAXIMUM PRECISION OF RESOLUTION WORKING IN FULL INTERPOLATION IN EVERY X, Y, Z AXIS.

The machine has an "Innovation Opinion", which makes it easier to co-finance the purchase from EU funds.

A high-class CNC milling machine designed for material removal, due to a whole range of configurations, it is used in many industries: industrial, electronic, welding, carpentry, advertising, etc. These are efficient and precise machines equipped with friendly CNC control systems, thanks to so they can be easily operated by both experienced and novice operators.

Training included in the price at our headquarters!

MACHINE AVAILABLE ON STOCK!

Technical parameters

Spindle 5.5kW / 18000rpm. inverter, air-cooled

Workspace 2100x3100 mm (up to 2680 x 3600 mm)

Maximum spindle height 350mm

Control DSP

Software resolution 0.001mm

Software INCLUDED

Power 400V

Weight 1450 kg

Machine dimensions 2680 x 3600 x 2200mm

Table height 715mm

Vacuum pump 7.5kW

Negative pressure 440mbar

Guides linear

Transfer rack (Z Axis - ball screw)

Axis drives hybrid servo drives

WARNING!

The machine is equipped with the function of remembering the last G-code track. In the event of a power failure or interruption, it restarts from the last point without losing time or material.

Optional equipment

Vacuum pump: Becker KVT 3.140 129 m3/h

The highest class safety barriers:

Optional top-quality light barriers available.

The safety zone determined by the sensors does not allow you to enter the machine's working area.

A set of barriers ensures the safety of the operator.

Z-axis gate height up to 450 mm

UCANCAM V11 software (possibility to import files from Corel, Autocad). File import/export, editor and insertion of these text.

Tool set: cutters, drills, holders.

*Unloading and placing the machine on the customer's side.

Equipment

Air-cooled spindle, premium version

Hybrid servo drives

Elevated gate in the Z axis by 350 mm

Vacuum table - 4 independent vacuum sections + T-groove table for manual material clamping (handles included)

Vacuum pump 5.5 kW included in the price

Tool measurement sensor included

Software included

Tools, collet set, leveling feet and other accessories

DSP control - digital data processing

The machine is equipped with the function of remembering the last G-code path - in the event of a failure or power interruption, it starts working from the last point without losing time and material.

Csdpfxeg Ngixs Afpopu

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

5,967 km

Dust and chip extraction

CORMAKDCV4500E

Call

Condition: new, Year of construction: 2025, Reliability confirmed by our customers dealing with large orders every day.

Pollutants from the filter fall directly into an airtight bag with quick discharge.

Designed for the filtration of primarily chips and dust with very fine granulation in the woodworking and furniture industry.

Advantages of

Cleaning quality guaranteed!

space-saving yet capable of extracting large quantities of dust and chips

trouble-free operation confirmed by production facilities dealing with large orders on a daily basis

Robust, vibration-free hardened construction for maintenance-free operation!

dynamically balanced metal rotor to reduce noise levels

metal intake nozzle with a diameter of 200 mm allows for a much higher air flow!!!

possibility to build a ceiling system and feed several machines working simultaneously with the DCV ECO extraction units

large filter surface area!

have a special blade design, which makes them more efficient and effective, as well as contributing to energy savings

very high tightness of the entire extraction system, guaranteeing the best quality of air inside the plant and, during the heating period, no loss of heat

quick change of film containers designed to keep the system 99.99% airtight.

The DCV 4500E is the next step in the production of efficient sawdust extraction, with the aim of constantly ensuring the same extraction performance throughout the entire extraction cycle.

This type of extraction will ensure perfection and cleanliness at the workplace, which will have a direct effect on the quality of your products.

Perfectly compatible with the following machines: sanding machines, format saws, veneering machines, panel saws, etc.

It is forbidden to use this extraction in explosive atmospheres

The extraction is used for working in the carpentry industry with sawdust, shavings, dust (it is not suitable for working with wet material such as wet sawdust)

polyester filter retains dust with a diameter of up to 5 microns, for the filtration of smaller particles it is necessary to use a filter such as HEPA

Technical parameters

CONTINUOUS DUTY MOTOR POWER S1

3.0 kW / 400 V, 50 Hz

RPM

2900 rpm

SUCTION OUTPUT

4500 m3/h

SUCTION NOZZLE DIAMETER

200 mm

SUCTION VELOCITY

Cjdjuc Uchjpfx Afpjpu

28-32 m/s

FILTER AREA

170 x 1035 mm

FILTER MATERIAL

Polyester, 5 micron

NUMBER OF FILTERS

12

DIMENSIONS

1530 x 665 x 2200 mm

WEIGHT

120 kg

Listing

Siedlce

Siedlce

5,967 km

Planer-thicknesser

CORMAKPT260 400V

Call

Condition: new, Year of construction: 2025, Planer-thicknesser – versatile woodworking machine

A planer-thicknesser is a versatile woodworking tool that allows for flattening, thicknessing, and smoothing wood surfaces. Ideal for carpentry and furniture manufacturing, it enables precise planing, edge processing, board production, creation of joinery components, and preparation of materials for gluing. This is a stable machine equipped with a high-quality cast iron table, cutting knives for material removal, an electric motor, and convenient adjustments that make it easy to operate.

Also known as a jointer, the planer-thicknesser is designed for initial processing of both rough and hard wood, as well as soft lumber. Its purpose is to level, smooth, and bring wood to the desired thickness through mechanical processes. It’s especially valuable in carpentry and furniture production, where precision and repeatability are essential.

Stable construction with enhanced weight for vibration resistance

The machine weighs 170 kg and features wide, ground cast iron tables (250 mm), ensuring excellent stability and safe operation.

Additional rubber feet allow vibration-free operation.

VERSION with a high-performance motor – Total power (S6): 2.6 kW

The PT260 planer-thicknesser stands out with its exceptionally powerful motor:

Total power (S6): 2.6 kW

Cpedpfxswt Axpj Afpou

Continuous power (S1): 2.0 kW

This is significantly more than what many competitor machines offer, translating into better performance and more stable operation.

Stronger motor = better efficiency and easier processing of hardwoods.

Hardwoods require more power to process, and this motor handles them with ease.

Effortless conversion from jointer to thicknesser

Switching between jointer and thicknessing functions is quick and simple.

It involves unlocking the eccentric clamps, lifting the tables, and repositioning the dust extraction hood.

Precision and ease of adjustment

Smooth table height adjustment with scale

Central column-mounted thicknessing table with handwheel for height regulation

700x150 mm aluminum tilting fence with scale strip for accurate angle settings from 90° to 45°

Technical Specifications:

Parameter Value

Cutter block diameter 75 mm

Cutter block speed 4000 rpm

Dust extraction port diameter 100 mm

Tilting fence angle range 90° – 45°

Number of knives 3

Knife dimensions 250x30x3 mm

Table dimensions 1100x250 mm

Thicknessing table dimensions 600x248 mm

Max. planing width (jointer) 250 mm

Max. planing depth (jointer) 5 mm

Max. thicknessing depth (single pass) 2.5 mm

Max. cutting depth (thicknesser) 3 mm

Max. workpiece height (thicknesser) 180 mm

Thicknesser feed rate 6 m/min

Fence dimensions 700x150 mm

Machine dimensions (L x W) 1100x250 mm

Weight 170 kg

Motor power S1: 2.0 kW / S6: 2.6 kW

Power supply 400 V

Listing

Siedlce

Siedlce

5,967 km

Stationary Edge Bander Machine

CORMAKEBM360B

Call

Condition: new, Year of construction: 2025, Professional EBM 360B table edge banding machine. The machine is designed for edge banding of both straight and curved elements. Ideal edge banding machine for medium and large workshops and carpentry shops. Pneumatic shears for cutting the edge (adhesive tape). Solid, strong construction. This machine feeds, cuts and glues the edge. The tape feeding and cutting sensor automatically takes the cut tapes from the container. Easy to use and conveniently placed control panel. Work comfort and failure-free operation of the machine are ensured. The indisputable advantage is the simple construction and intuitive operation.

TECHNICAL PARAMETERS

EDGE WIDTH

10-60 (68) mm

EDGE THICKNESS

0.3-3 mm

MINIMUM WORKING RADIUS

20mm

MAX. PERMITTED CUTTING WIDTH

50 mm

HEATING POWER

2 kW

POWER SOURCE

400V

MOTOR

0.18 kW, 0.37 kW, 0.4 kW

FEED SPEED

0-14 m/min.

AIR PRESSURE

6 BAR

DIMENSIONS

1550 x 800 x 1000

Codpfswl Eaaox Afpopu

WEIGHT

185 kg

Trust Seal

Dealers certified through Machineseeker

Listing

Siedlce

Siedlce

5,967 km

Band saw machine 125mm

CORMAKBS-128HDRC 400V

Call

Condition: new, Year of construction: 2025, functionality: fully functional, Band saw for metal with optimal cutting range, commonly used in carpentry, production and craft facilities.

Machine description

CORMAK BS 128HDRC band saw for metal with optimal cutting range, designed for professional craftsmen, distinguished by efficiency and easy handling. Arm swivelling in both directions is a very big advantage in angled cutting. Despite small dimensions, its big weight (103 kg) makes it very stable and vibration-free during cutting larger materials. Element cut can be fed manually or via feeding machines. Feed during cutting is gravitational, with oil flow in a two-chamber hydraulic cylinder. Arm lowering control is ensured by a valve controlling oil flow between chambers of cylinder. Straight cut is achieved by a set of bearings guiding the band. Machines are equipped with a limiting switch and ON/OFF switch compliant with IP54. Swivelling saw frame for double bevelling within -45o - + 60o.

Technical data

Cutting band size 1640×13×0.65 mm

Cutting speed 23/34/54 m/min

Power 0,55 kW/230V

Arm lowering control stepless, through hydraulic cylinder

Cutting range -45° - + 60°

Dimensions 942×442×548 mm

Weight 103 kg

Maximum cutting range [mm]

Angle

0°.....ø125 mm.....100×150 mm....100×100 mm

-45°.....ø90 mm.....90×75 mm.....90×90 mm

+45°.....ø90 mm.....90×75 mm.....90×90 mm

+60°.....ø55 mm.....55×55 mm.....55×55 mm

Default equipment

3rd generation hydraulic cylinder

Cpodpjwq A Dyofx Afpeu

Table for vertical cuts

Quick-clamping vice

Coolant system

Workpiece limiter - bumper

Automatic limiting switches

Modern thermal engine protection

Mobile base with four wheels

User manual

The price is a net price. Price does not include shipping costs.

For more information, please contact us by phone or e-mail. We invite you to familiarize yourself with the offer on our website.

Listing

Siedlce

Siedlce

5,967 km

Press brake

CORMAKUltimate PRO 32170

Call

Condition: new, Year of construction: 2025, Cormak press brakes are advanced devices that enable precise bending of sheet metal thanks to appropriately selected punches and dies. Our offer includes models equipped with DELEM DA-53TX controllers as standard and optionally DELEM DA53T, DA-58T, DA-66T, DA69T and CYBELEC 12 controllers, which provide a wide range of functions that allow for the implementation of the most demanding bending tasks.

Main Features:

Front supports: 2 pieces, ensuring stability during bending operations

X-axis AUTOMATIC SERVO

Axes Y1, Y2, – AUTOMATIC (optional SERVO motor)

R-axis – Automatic SERVO

Automatic adjustment / compensation of the deflection arrow

Front support on linear guides

As standard, the machine is equipped with hardened, divided punches and 4V (42CrMo) dies

Machine Description

Ultimate press brakes are an advanced tool used in the industry for edge processing and bending materials. It is a versatile device that allows precise and effective finishing of edges of various types of materials, such as steel, aluminum and plastics.

Ultimate press brakes have been designed with efficiency and reliability in mind. It is equipped with a solid structure that ensures stability during operation. The machines also have advanced control systems that allow programming of various operating parameters, such as edge speed, bending angle and pressure force.

One of the main advantages of the Ultimate press brakes is their ease of use. The intuitive user interface allows the operator to easily program and control the machining process. Additionally, the presses are equipped with advanced safety systems that ensure safe use. Thanks to their high performance, the EASY press brakes are the ideal solution for manufacturers who require fast and precise edge processing. It can be used in various industries, such as the metal industry, carpentry, furniture production and the plastics industry.

Technical parameters

Max. thickness of bent sheet metal (S235) up to 6.0 mm

Nominal pressure 1700 kN

Maximum length of bent sheet metal 3200 mm

Cpedswq Dyvjpfx Afpou

Depth of cut in beams (throat) 550 mm (option 620mm)

Maximum stroke of moving beam 200 mm (option 300mm or 400mm)

Maximum opening height 390 mm

Distance between beams 2700 mm

Rear bumper departure 650 mm (option 1000mm)

SERVO motor power 7.5 kW

Length 3870 mm

Width 1600 mm

Height 2600 mm

Weight 7500 kg

Listing

Siedlce

Siedlce

5,967 km

Sliding Table Saw

CORMAKPS12E-3000

Call

Condition: new, Year of construction: 2025, The PS12E-3000 format saw is a professional carpentry tool that stands out for its powerful specification and its ability to perform large-scale precision cuts. This advanced circular saw has been developed for a variety of woodworking tasks and is the ideal tool for demanding users.

The main features of the saw, the PS12E-3000 wood panel saw:

Two cutting discs: The saw is equipped with two cutting discs - a main disc and an undercutting disc - which provides ample cutting capacity for different types of wood materials.

Large format table: One of the main advantages of this model is the extra-wide, bearing-mounted format table with support, which allows precise processing of large-format chipboard up to almost 3,000mm long and other large-sized wood materials.

Additional undercutter: The additional undercutting blade makes the saw ideal for cutting furniture board and particleboard, eliminating the risk of splintering and ensuring an even cut.

Disc inclination: The cutting disc can be tilted from 90° to 45°

Maximum bar length: This saw is fitted with a bar of an impressive length of 2,300 mm

Disc replacement: The replacement process is quick and efficient, thanks to the ability to remove the metal top and unscrew the blade.

Saw blade guard: The saw has an effective saw blade guard, which can also be connected to the extraction system to help keep the work area clean.

Csdpfx Aevugc Asfpopu

Powerful motor: The saw blades are driven by a powerful 3.8 kW, 400V motor, which guarantees smooth operation and efficient cuts.

Control panel: The machine's control panel is located on the underside of the saw and includes an emergency stop, a knob for angle cuts (45°) and a knob for blade height adjustment with a locking mechanism.

Additional measuring instruments: All guides are equipped with length and cutting angle scales, allowing the required angle and length to be quickly set without the need for additional measurements.

Extraction compatibility: The saw is suitable for connection to a sawdust and chip extraction system with a suction nozzle diameter of 100 mm, which contributes to keeping the workplace clean.

Application of the saw, format saw for wood:

The PS12E-3000 format saw is an advanced tool that combines durability, precision and performance, making it the ideal choice for professional woodworkers and everyday woodworkers. Its versatile capabilities and advanced features allow it to handle a wide variety of woodworking projects and tasks in both industrial and craft settings.

DIMENSIONS OF THE MOVING TABLE 3000 x 270 mm

MAIN TABLE DIMENSIONS 800 x 385 mm

SIDE AUXILIARY TABLE DIMENSIONS 880 x 800 mm

BAND WIDTH 1220 mm

SAW TILT 0-45°

CUTTING HEIGHT AT 90° 100 mm

CUTTING HEIGHT AT 45° 80 mm

MAXIMUM SAW SIZE 315 mm

MAXIMUM Blade size 100 mm

MAIN SAW RPM 4000 rpm

CUTTING SAW RPM 5800 rpm

POWER OF ENGINE S6 5,3 kW / 7,1 hp

POWER OF ENGINE S1 3,8 kW / 5,1 hp

400 V POWER SUPPLY

WEIGHT 309 kg

Listing

Siedlce

Siedlce

5,967 km

Radial Fan-Blower

CORMAKFAN2200

Call

Condition: new, Year of construction: 2025, The centrifugal fan allows for operation with increased vacuum power to extract various types of pollutants, thanks to a special blade system which has been profiled at an appropriate angle. The radial fan has been developed for use in the carpentry, furniture, automotive, agricultural and manufacturing industries.

Thanks to the many years of experience of our CORMAK team, radial fans of the FAN series were created. Designing a new technological line allowed us to create the LineWind metal turbine system. This is the most important feature of the centrifugal fans, enabling them to extract all kinds of pollutants with increased vacuum power thanks to a special blade system that has been profiled at the right angle. The centrifugal fan was developed for use in the carpentry, furniture, automotive, agricultural and manufacturing industries.

Radial fans are used for:

transport of shavings, sawdust, small granulates

dusty air

Csdpevugg Usfx Afpopu

local exhaust ventilation

drying systems

dehumidifiers

Multi-vane metal rotor!

High efficiency ensured by a balanced impeller Thermal winding protection (thermal sensor).

The extraction design has been enhanced with additional anti-vibration feet in the base to guarantee a stable and vibration-free operation of the unit.

An emergency shutdown button meets the requirements of the PN-EN ISO 12100 and PN-EN ISO 13850 standards.

An additional advantage is the use of branded flexible and resistant seals in sensitive areas, allowing high vacuums to be achieved without losses at individual connection points.

Reliability confirmed by Polish users who enjoy working with our machines every day.

Technical specifications

MAX. AIR CAPACITY 4000 m3/h

inlet diameter 200 mm

discharge diameter 180 mm

ENGINE SPEED 2850 rpm

DIMENSIONS 575 x 550 x 500 mm

MOTOR POWER / VOLTAGE 2,2 kW / 400 V

WEIGHT 35,5 kg

We make it easier for you to find: "carpentry"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Carpentry (171)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month