Used travelling column milling machines for sale (108)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Metal working machinery & machine tools Milling machines Travelling column milling machines

Auction

Auction ended

Steiermark

Steiermark

6,381 km

Travelling column milling machine

ANAYAKHVM 6000

Year of construction: 2001, operating hours: 27,046 h, condition: excellent (used), functionality: fully functional, CNC travelling column milling machine in cast design

Highly stable design thanks to 3-fold guided X-axis and fixed table

Machine is provided EXW

TECHNICAL DETAILS

X-axis (longitudinal) linear guide: 5,300 mm (3-fold)

Y-axis (transverse) linear guide: 1,000 mm (2-fold)

Z-axis (vertical) flat guide: 1,500 mm (2-fold)

Speed range: 60 to 3,000 min-1

Tool holder: SK 50

tool changer: 40-fold

Tightening bolt: DIN 69872-B

Driving power: 30 kW

tool dimensions: max. L=350mm / DM=200mm

table dimensions: 6000x1000mm

Heidenhain control: TNC426 with color screen and handwheel

rapid traverse X, Y, Z axis: 10.000 mm/min

clamping surface: 6.000 x 1.000mm

T-slots: 22 H12 / distance 130mm

Central T-slot: 22 H7

MACHINE DETAILS

Duty cycle: 62,774 hours (as of 11/2022)

Coolant outside: 1,1KW with 50l/min.

Bsdpfxolhqkhs Afhecu

Machine weight: 43.000kg

EQUIPMENT

- Electric handwheel Heidenhain

- Pendulum machining function monitored with light barriers

- New X-axis covers

- Chip conveyor 2-fold

- New milling head bearing 2021

- Operating manual / Documentation

CONDITION

- Service and maintenance work has been carried out

- Geometry in order

- Suitable for pendulum machining

Machine available from July-August

Listing

Österreich

Österreich

6,437 km

Travelling column milling machine

SHWUS5-T

Call

Condition: used, Year of construction: 2011, functionality: fully functional, machine/vehicle number: 3261, travel distance X-axis: 2,000 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 1,300 mm, rotary table diameter: 1,600 mm, Equipment: rotational speed infinitely variable, Used Milling/Turning Center SHW UniSpeed 5T

MC-No. 3261 – Year of manufacture: 2011

Travel paths:

X = 2,000 mm | Y = 1,300 mm | Z = 1,300 mm

Design:

Self-rigid machine frame without elaborate foundations. Precision compact roller guides on all axes. Machine column in portal construction, spindle head and saddle made from GGG 60 cast iron with hydraulic weight compensation.

Drive & Feed:

Digital AC individual drives, stepless 2–30,000 mm/min, acceleration 2 m/s². Direct measuring system for high accuracy.

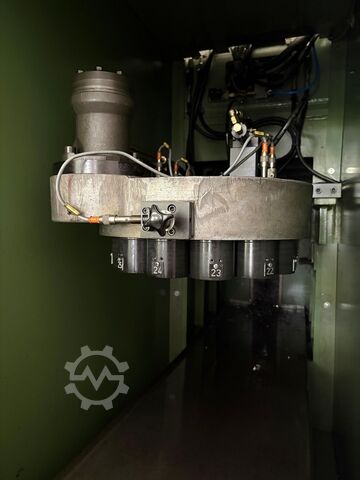

Universal Milling Head (orthogonal):

- GGG 60 cast iron, automatic 360°/180° swivel, 64,800 CNC-controlled positions

- SK 50, tool pull-in force 20 kN

- Power: 26 kW (100% duty cycle) / 36 kW (40% duty cycle), 22–6,000 rpm

- Hydromechanical quick tool clamping

CNC Rotary Table:

- Ø 1,000 mm, planarity 0.015 mm

- Turning: up to 250 rpm | Torque: 2,700 Nm

- Table load: Milling 6,000 kg, Turning 3,000 kg

- Max. swing diameter: 1,800 mm

Balancing System:

Integrated system for vibration monitoring & correction (DIN ISO 1940 G 6.3 to >G 3). Operation via Siemens 840D.

Tool Changer:

- Chain magazine for 90 tools

- SK 50, max. Ø 125/250 mm, length 400 mm, weight 25 kg

- Horizontal tool change, fixed-location coding, air-blow spindle protection

Control:

Siemens 840D, mounted swiveling on the machine.

Electrics:

Total connected load approx. 80 kVA. Control voltage 24 V, protection class IP 54, EN 60204. Control cabinet with integrated cabinet cooler (two-chamber system, airtight, with dehumidification).

Cooling & Lubrication:

- ICS & shower ring (switchable), 500 l tank, max. 40 bar

- Minimum quantity lubrication (MQL, Lubrix 850) via spindle

- Rinse gun, frame flushing, air/coolant changeover

- Lubrication: central for guides, spindle grease-lubricated, milling head oil mist

Chip Conveyor:

Hinged belt, X-axis 2,000 mm, width 350 mm, discharge height 1,250 mm

Additional Systems:

- Single-channel collision monitoring

- Protective air on glass scales

- Wireless 3D probe

- Extended milling head swivel range -90° to +110°

- VisioPort for clear view

- Rotary union in rotary table for clamping hydraulics incl. clamping monitoring

Bjdpew Eb Itjfx Afhscu

- Zero-point clamping system with control panel buttons

- Safety glass (18 mm)

- Air cleaning unit ILT Unifil 1 MRV70-4.0 (4,200 m³/h)

- External B-MPI handheld device with handwheel, override, emergency stop

- Energy connections: compressed air 4–6 bar (G¼)

Paintwork:

Base color RAL 7004 signal grey, functional units RAL 7016 anthracite grey and RAL 9011 graphite black, silk matte, oil & soda resistant.

Listing

Oelde

Oelde

6,920 km

Travelling column milling machine

DECKEL MAHODMF 260 New Design

Call

Condition: used, Year of construction: 2010, x-travel 2.600 mm

y-travel 700 mm

z-travel 700 mm

control iTNC 530 Heidenhain

turning speed range - main spindle 20 - 18.000 min/-1

power capacity - main spindel 35 / 25 kW

tool taper SK 40

table surface area 2.900 x 700 mm

max. table load 2.150 kg

number of toolpositions 30 pos.

tool taper SK 40

max. tool diameter 80 mm

max. tool-dia with free toolbox 130 mm

max. tool length 300 mm

max. tool weight 6,0 kg

rapid traverse ( X / Y / Z ) 40 m/min

Bcedpfx Aev Dxxnefhju

feed speeds max. 40.000 mm/min

feed power max. 8 kN

total power requirement 54 kVA

weight of the machine ca. 14,4 t

dimensions of the machine ca. 8,0 x 5,6 x 2,8 m

CNC - Travel Column Milling Machine

DECKEL MAHO - DMF 260 New Design

- NC dividing head (A-axis)

- Operating hours: 18.709h spindle run

- overhauld spindle installed (Dec 2023)

- Z-axis weight compensation changed (Feb 2023)

- Production package

- Option: tool clamping for tightening bolts

- WITHOUT vices!

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Czech Republic

Czech Republic

6,311 km

Milling machine with moving column

TOS KUŘIMFREP-D 20X40A

Call

Condition: excellent (used), Year of construction: 1986, functionality: fully functional, machine/vehicle number: 50166, travel distance X-axis: 9,000 mm, travel distance Y-axis: 2,295 mm, travel distance Z-axis: 2,500 mm, rapid traverse X-axis: 9 m/min, rapid traverse Y-axis: 1 m/min, rapid traverse Z-axis: 2 m/min, feed rate X-axis: 3 m/min, feed rate Y-axis: 1 m/min, feed rate Z-axis: 2 m/min, spindle speed (max.): 710 rpm, spindle speed (min.): 15 rpm, rotational speed (max.): 710 rpm, total width: 8,500 mm, total height: 7,150 mm, total length: 20,720 mm, table length: 9,000 mm, table width: 2,000 mm, torque: 6,500 Nm, clearance between the columns: 2,750 mm, year of last overhaul: 2003, table height: 1,000 mm, table load: 45,000 kg, spindle motor power: 50,000 W, workpiece weight (max.): 45,000 kg, Equipment: documentation/manual, rotational speed infinitely variable, GENERAL MACHINE CHARACTERISTICS

The machine features a rigid gantry design with a movable table. The gantry is equipped with a height-adjustable crossbeam, which can be fitted with one or two vertical spindle heads of type VFS 160. Additionally, the gantry can accommodate one or two lateral (horizontal) spindle heads VFS 160.

The specified spindle head types can be equipped with additional spindle heads, with up to 4 available.

The clamping surface of the machine consists of two connected clamping tables, which can also be used separately when disconnected (only one can be active at a time).

Clamping Table

- Dimensions of one table: 2,000 x 4,000 mm

- Total length of connected tables: 9,000 mm

- Clamping surface of connected tables: 8,500 mm

- Clamping T-slots (width x spacing x quantity): 36mm x 180mm x 11 pcs

- Working table height from base: 1,000 mm

- Load per meter of table length: 5,000 kg

- Table travel: 4,250 mm (connected tables: 9,000 mm)

- Working feed rate: 15 – 3,000 mm/min

- Rapid traverse: 9,000 mm/min

Gantry with Height-Adjustable Crossbeam

- Clearance between columns: 2,750 mm

- Crossbeam vertical adjustment: 2,295 mm

- Crossbeam travel: 750 mm/min

Vertical Spindle Head VFS 160

- Toolholder taper: ISO 60

- Spindle power: 50 kW

- Speed range: 15 – 710 rpm

- Working feed: 10 – 2,000 mm/min

- Rapid traverse: 2,000 mm/min

- Distance from spindle nose to clamping table: 425 – 2,720 mm

Horizontal Spindle Head VFS 160

- Toolholder taper: ISO 60

- Spindle power: 50 kW

- Speed range: 15 – 710 rpm

- Working feed: 5 – 1,000 mm/min

- Rapid traverse: 1,000 mm/min

- Distance from spindle nose to table centering T-slot: 377 – 1,177 mm

Overall Machine Dimensions (L x W x H):

20,720 mm x 8,500 mm x 7,150 mm

Additional Spindle Heads:

NVS Head (Extension Adapter)

- Toolholder taper: ISO 60

- Speed: 15 – 710 rpm

- Max. transmitted power from 60 rpm = 40 kW

- Max. torque: 6,500 Nm

HFUS Head (Universal Milling Head)

Bjdpsxpudtefx Afhscu

- Toolholder taper: ISO 60

- Speed: 15 – 710 rpm

- Max. transmitted power from 80 rpm = 22 kW

- Max. torque: 2,700 Nm

- Swivel range vertical axis: 360°

- Swivel range horizontal axis: 360°

- Quill adjustment: 50 mm

HFOS Head (Double-Sided Right-Angle Milling Head)

- Toolholder taper: ISO 60

- Speed: 15 – 710 rpm

- Max. transmitted power from 60 rpm = 40 kW

- Max. torque: 6,500 Nm

Listing

Babberich

Babberich

7,060 km

Bed milling machine SORALUCE SP-6000

SoraluceSP 6000

Call

Condition: good (used), Year of construction: 1995, travel distance X-axis: 4,500 mm, travel distance Y-axis: 1,200 mm, travel distance Z-axis: 1,600 mm, table length: 6,000 mm, table width: 1,000 mm, table load: 16,500 kg, ATC Chain Tool Changer 30 Positions

Automatic head 2.5 x 2.5 ( Overhauled in 2023)

AME Chip conveyor new 2013

HeidenHain HR410 Handwheel

Under power

X-Axis: 4500mm

Y-Axis: 1200mm

Z-Axis: 1600mm

Table Length: 6000mm

Table Width: 1000mm

Table load: 16500

Power on spindle: 32kW

Spindle speeds: 3000Rpm

Spindle Taper: 50ISO/Bt/Mk

Feed rate X-Axis: 25000mm/min.

Feed rate Y-Axis: 25000mm/min.

Feed rate Z-Axis: 25000mm/min.

Millinghead auto-index:2.5 x 2.5°

Length: 10100mm

Bedpfx Aexf Hitsfhecu

Width: 6300mm

Height: 4350mm

Weight: 28500kg

Listing

Landsberg am Lech

Landsberg am Lech

6,716 km

Travelling column milling machine

MetbaMB 1

Call

Condition: used, functionality: fully functional, Metba MB1

Bcjdpfx Ajv H Ukrefheu

Tool milling machine Metba MB-1

€6,900,-- / net

Location: 86928 Hofstetten

Listing

Sheffield

Sheffield

7,565 km

Milling Machine

SoraluceSP10000

Call

Condition: good (used), Year of construction: 2002, functionality: fully functional, USED Soraluce Soramill Model SP 10000 Travelling Column, Table Type CNC Milling Centre, with Automatic Oil Mist Lubricated Orthogonal Milling Head with 1 X 1 Degree Indexing and HEIDENHAIN TNC 430 M Control System. Year 2002 SN 8647

Table Area - 10000 x 1100 mm

Column Traverse (X) - 8500 mm

Vertical Traverse (Y) - 1600 mm

Ram Traverse (Z) - 1200 mm

Spindle Motor - 28 kW

Spindle Taper - Standard ISO 50 BT50 tooling

Pullstud - DIN 6987 2-Form A. ISO 7388/2-Form A

Independent Gearbox with 2 Ranges

Speed Range - 20 to 4000 RPM

Feed Range - 5 to 5000 mm/min

Rapid traverse rate - (X, Y, Z) 15,000 mm/min

Preloaded double nuts and recirculating ballscrews to each axis.

Linear Guiding System with recirculating cylindrical rollers and steel guideway assemblies in X, Y and Z axes

Independent A.C Drive motor to each axis.

Linear Transducer in X, Y and Z-axes with air purge system.

Automatic tool clamping. Automatic hydraulic tool releasing device.

CNC Control HEIDENHAIN TNC-430-M. (Flat TFT screen with digital drives) 9 axes CNC and 1 spindle, 5 of them simultaneously interpolated.

Working area lighting

Bodpfxjr Hr Ars Afhscu

Electrical cabinet cooling system

Electrical cabinet lighting

Heidenhain HR410 portable electronic handwheel with 3m spiral cable

Horizontally articulated pendant for CNC control

Orthogonal head 28KW, 800Nm, 1deg x 1 deg, 4000rpm oil lubricated Price includes oil cooling unit for both head and gearbox. Option G2, Ram prepared for 4000rpm, is also included.

Coolant through the spindle type AD.

Coolant system with 500l capacity tank with two pumps providing low and high pressure of 3 and 8 bars and 50l/min flow. The system includes a combined paper and magnetic drum-filtering unit.

Standard operators platform fixed to the column

40 tools capacity toolchanger magazine, BT50

Max. Tool length = 400 mm.

Max. Tool diameter: - With full magazine = 120 mm. With adjacent position empty = 250 mm.

Max. Tool weight = 20 kg.

Mean tool weight with full magazine = 10 kg.

Max. Permitted total weight = 20 kg.

Swarf Conveyor

Hinge type conveyor belt

Machine preparation for the addition of a 4th axis electro-mechanical table.

Splash Guarding against swarf at the table front and both sides. Consists of four sliding front doors with a height from the floor of 2.100mm and a length of 1.700mm each one. Manually operated opening and closing with mechanical interlock. The doors can be opened for the full longitudinal traverse. The rear of the table is open.

Protection in the back and both lateral sides of the machine column.

Listing

Sheffield

Sheffield

7,565 km

Travelling Column Milling Machine

SoraluceSP10000

Call

Condition: good (used), Year of construction: 2002, functionality: fully functional, USED Soraluce Soramill Model SP 10000 Travelling Column, Table Type CNC Milling Centre, with Automatic Oil Mist Lubricated Orthogonal Milling Head with 1 X 1 Degree Indexing and HEIDENHAIN TNC 430 M Control System. Year 2002 SN 8647

Table Area - 10000 x 1100 mm

Column Traverse (X) - 8500 mm

Vertical Traverse (Y) - 1600 mm

Ram Traverse (Z) - 1200 mm

Spindle Motor - 28 kW

Spindle Taper - Standard ISO 50 BT50 tooling

Pullstud - DIN 6987 2-Form A. ISO 7388/2-Form A

Independent Gearbox with 2 Ranges

Speed Range - 20 to 4000 RPM

Feed Range - 5 to 5000 mm/min

Rapid traverse rate - (X, Y, Z) 15,000 mm/min

Preloaded double nuts and recirculating ballscrews to each axis.

Linear Guiding System with recirculating cylindrical rollers and steel guideway assemblies in X, Y and Z axes

Bsdpouv Hrdefx Afhecu

Independent A.C Drive motor to each axis.

Linear Transducer in X, Y and Z-axes with air purge system.

Automatic tool clamping. Automatic hydraulic tool releasing device.

CNC Control HEIDENHAIN TNC-430-M. (Flat TFT screen with digital drives) 9 axes CNC and 1 spindle, 5 of them simultaneously interpolated.

Working area lighting

Electrical cabinet cooling system

Electrical cabinet lighting

Heidenhain HR410 portable electronic handwheel with 3m spiral cable

Horizontally articulated pendant for CNC control

Orthogonal head 28KW, 800Nm, 1deg x 1 deg, 4000rpm oil lubricated Price includes oil cooling unit for both head and gearbox. Option G2, Ram prepared for 4000rpm, is also included.

Coolant through the spindle type AD.

Coolant system with 500l capacity tank with two pumps providing low and high pressure of 3 and 8 bars and 50l/min flow. The system includes a combined paper and magnetic drum-filtering unit.

Standard operators platform fixed to the column

40 tools capacity toolchanger magazine, BT50

Max. Tool length = 400 mm.

Max. Tool diameter: - With full magazine = 120 mm. With adjacent position empty = 250 mm.

Max. Tool weight = 20 kg.

Mean tool weight with full magazine = 10 kg.

Max. Permitted total weight = 20 kg.

Swarf Conveyor

Hinge type conveyor belt

Machine preparation for the addition of a 4th axis electro-mechanical table.

Splash Guarding against swarf at the table front and both sides. Consists of four sliding front doors with a height from the floor of 2.100mm and a length of 1.700mm each one. Manually operated opening and closing with mechanical interlock. The doors can be opened for the full longitudinal traverse. The rear of the table is open.

Protection in the back and both lateral sides of the machine column.

Auction

Auction ended

Nordrhein-Westfalen

Nordrhein-Westfalen

6,855 km

Travelling column milling machine

ANAYAKHVM 6000 P

Condition: ready for operation (used), Year of construction: 2004, operating hours: 8,087 h, functionality: fully functional, travel distance X-axis: 5,300 mm, travel distance Y-axis: 1,500 mm, travel distance Z-axis: 2,000 mm, spindle speed (max.): 5,000 rpm, table height: 925 mm, The machine has undergone a complete inspection, with the milling head and the telescopic cover of the X-axis repaired. Additionally, the control panel and the polycarbonate doors have been renewed, and the machine has been thoroughly cleaned.

TECHNICAL DETAILS

Travel distances

X-axis: 5,300 mm

Y-axis: 1,500 mm

Z-axis: 2,000 mm

A-axis: +45° to −225°

B-axis: +165° to −18°

Spindle data

Spindle speed range: 60 – 5,000 rpm

Tool holder: SK 50 DIN 69871

Spindle outer diameter (front bearing): 140 mm

Bsdpfx Afsxbd A Njhscu

Spindle bore: 90 mm

Table dimensions

Clamping area: 6,000 × 1,200 mm

Table height: 925 mm

Feed rate: 10 – 6,000 mm/min

Rapid traverse (X & Y): 15,000 mm/min

Rapid traverse (Z): 10,000 mm/min

MACHINE DETAILS

Control system

Manufacturer: HEIDENHAIN

Model: TNC 530

Operating hours

Spindle hours: 8,087 h

Control system on-time: 3,785 h

Machine on-time: 30,238 h

Note: The machine has already been dismantled.

Listing

Babberich

Babberich

7,060 km

Bed type milling machine ANAYAK HVM 3800

ANAYAKHVM 3800

Call

Condition: good (used), Year of construction: 2001, travel distance X-axis: 3,200 mm, travel distance Y-axis: 1,200 mm, travel distance Z-axis: 1,460 mm, table length: 3,800 mm, table width: 1,000 mm, table load: 30,000 kg, Chip conveyor

Double doors front side

Chain Tool chnager 30 positions

Central lubrication

IKZ 16 Bar and 2,2 kW Flow 16L/Min

Tool blocking power 1968 daN

Full set books and 1e owner machine

X-Axis: 3200mm

Y-Axis: 1200mm

Z-Axis: 1460mm

Table Length: 3800mm

Table Width: 1000mm

Table load: 30000

Bcedpfxexc Hh Do Afhsu

Power on spindle: 41kW

Spindle speeds: 3000Rpm

Spindle Taper: 50ISO/Bt/Mk

Feed rate X-Axis: 10000mm/min.

Feed rate Y-Axis: 10000mm/min.

Feed rate Z-Axis: 10000mm/min.

Millinghead auto-index:2.5 x 2.5°

Working hours: 10659H

Length: 8820mm

Width: 6250mm

Height: 3910mm

Weight: 33000kg

Please Note: The information on this page has been obtained to the best of our ability and belief, and from the manufacturers where possible. It is given in good faith, but its accuracy can not be guaranteed. Accordingly, it will not form a representation or constitute contractual terms. We advise you to check any vital details!

Listing

Babberich

Babberich

7,060 km

Travelling column milling machine 8000 3300 1500

SoraluceFS 8000

Call

Condition: excellent (used), Year of construction: 2006, travel distance X-axis: 8,000 mm, travel distance Y-axis: 3,300 mm, travel distance Z-axis: 1,500 mm, Manufacturer: SORALUCE

Type: FS 8000

Control: HeidenHain iTNC 530

Year of manufacture: 2006

ATC Chain 40 positions

Max. tool size Ø 125 x 400 mm

Machine prepared for rotary table

Chip conveyor

Central lubrication

Stroke with vertical head rotated 3300 mm

Specifications

Metric US Standard

X-Axis

8000 mm

Y-Axis

2800 mm

Z-Axis

1500 mm

Spindle power

30 kW

Spindle speed

5000 Rpm

Tool holder

50 ISO/Bt/Mk

X - Axis feed

15000 mm/min.

Y - Axis feed

15000 mm/min.

Z - Axis feed

15000 mm/min.

Milling head auto-index

2.5 x 2.5 °

Dimensions (approximate)

Length

17500 mm

Width

4050 mm

Height

5020 mm

Bedpexc Emxsfx Afhscu

Weight

38400 kg

Please note: The information on this page was provided to the best of our knowledge and, where possible, obtained from the manufacturer. The information is given in good faith, but accuracy cannot be guaranteed. Accordingly, they do not constitute representation or contractual terms. We recommend that you check all important details.

Listing

Heidenheim an der Brenz

Heidenheim an der Brenz

6,769 km

Travelling column milling machine 7x1.6x1.4m

ScharmannEcoCut 1.6 XZ

Call

Condition: refurbished (used), Year of construction: 2007, functionality: fully functional, travel distance X-axis: 7,000 mm, travel distance Y-axis: 1,600 mm, travel distance Z-axis: 1,400 mm, feed length X-axis: 7,000 mm, feed length Y-axis: 1,600 mm, feed length Z-axis: 1,400 mm, Complete with all assemblies required for installation and commissioning

x = 7 m y = 1.6 m z = 1.4 m (800 mm + quill = 600 mm) General overhaul in 2007, year of manufacture 1991

Rapid traverse: 12,000 mm/min; w-axis: 6,000 mm/min

Fitted with new Siemens Sinumerik 840D control system, new drive motors, refurbished guideways, and new control cabinets. ECOCUT 1 was only operated for a few hours thereafter.

TDV 2 rotary table, max. workpiece weight 6 t / clamping area 1,000 x 1,000 mm

TDV 3 rotary table, max. workpiece weight 12 t / clamping area 1,250 x 1,600 mm

Accessories: 2 right-angle milling heads / chain-type automatic tool changer / platen table / full enclosure / Knoll hopper feeding system / extraction unit / coolant system with belt filter. Supplied with all BWF fixtures required for installing the machine bed and clamping plate.

Bjdpfxsw Dhm Hj Afhjcu

Listing

Bächingen an der Brenz

Bächingen an der Brenz

6,758 km

Travelling column milling machine

DonauDanusys 1510 S

Call

Condition: refurbished (used), Year of construction: 2005, functionality: fully functional, travel distance X-axis: 1,500 mm, travel distance Y-axis: 1,000 mm, travel distance Z-axis: 700 mm, spindle speed (max.): 8,000 rpm, Travelling column machine

Completely overhauled in 2025

Work table clamping area mm 1500 x 1000

Bsdpfxsw I Tm Se Afhecu

Table height mm 750

Number of T-slots 7

T-slot size to DIN 650 mm 18

Travels

X-axis mm 1500

Y-axis mm 1000

Z-axis mm 700

Distance table top – spindle nose min/max mm 150 / 850

Main spindle drive for speed 8000 rpm

Tool holder SK 40

AC motor, frequency controlled kW 26 at 44% duty cycle

Speed range: rpm 15 – 8000

Torque Nm 245

Internal coolant supply (IKZ)

Chip conveyor with belt filter

Feed drives

X-axis AC servo motor kW 3.5

Y-axis AC servo motor kW 2.0

Z-axis AC servo motor kW 3.5

Rapid traverse speeds (X/Y/Z): m/min 30/30/20

Indirect measuring system

Accuracy

Positioning accuracy X, Y axis over 1000 mm: mm ± 0.0150

Repeatability X, Y axis: mm ± 0.0075

Positioning accuracy Z axis: mm ± 0.0150

Repeatability Z axis: mm ± 0.0075

Tool magazine 24 positions

mounted on the left side of the machine

- Tool stations 24

- Tool shank (DIN 69871 / 69872) SK 40

- Max. tool diameter mm 76

- Max. tool length mm 250

- Max. tool weight kg 8

Machine control: Heidenhain iTNC530

Auction

Auction ended

Niedersachsen

Niedersachsen

6,757 km

CNC portal travelling column machining center

MATEC30 P

Condition: not inspected (used), Year of construction: 1998, functionality: unexamined, machine/vehicle number: 0112, travel distance X-axis: 1,500 mm, travel distance Y-axis: 3,500 mm, travel distance Z-axis: 1,000 mm, spindle speed (max.): 9,000 rpm, Equipment: documentation/manual, No reserve price – guaranteed sale to the highest bidder!

Loading can take place on 08.09.2025 or 09.09.2025!

TECHNICAL DETAILS

Travel distances

Travel X: 1,500 mm

Travel Y: 3,500 mm

Travel Z: 1,000 mm

Worktable dimensions: 4,500 x 1,600 mm

Spindle and Tooling

Max. spindle speed: 9,000 rpm

Swivel range of angular head (B-axis): ±90°

Tool holder: SK 40

MACHINE DETAILS

Dimensions & Weight

Dimensions (L x W x H): 8,000 x 5,000 x 3,700 mm

Weight: 32,000 kg

EQUIPMENT

Bcjdpfxew Hrh He Afhju

2 ALMATIC machine vices

Various clamping devices for the machine

Technical documentation

Listing

Ellwangen (Jagst)

Ellwangen (Jagst)

6,769 km

Gantry-type milling machine X = 4,000 mm

SHWPowerSpeed 5 - Heidenhain iTNC 530

Call

Condition: excellent (used), functionality: fully functional, travel distance X-axis: 4,000 mm, travel distance Y-axis: 2,100 mm, travel distance Z-axis: 1,300 mm, rapid traverse X-axis: 30 m/min, rapid traverse Y-axis: 30 m/min, rapid traverse Z-axis: 30 m/min, feed rate X-axis: 30 m/min, feed rate Y-axis: 30 m/min, feed rate Z-axis: 30 m/min, spindle speed (max.): 6,000 rpm, spindle speed (min.): 36 rpm, table length: 4,000 mm, table width: 1,500 mm, tank capacity: 500 l, SHW PowerSpeed 5

Travel Ranges

• X-axis (bed): 4,000 mm

• Y-axis (vertical): 2,100 mm

• Z-axis (spindle horizontal): 1,300 mm

Control System

• CNC control: Heidenhain iTNC 530

Feed Speed

• X, Y, and Z axes: 2 - 30,000 mm/min

• Acceleration: 3.5 m/s²

Universal Milling Head in Orthogonal Design

• Milling head swivel range (mounting): 360 x 1 degree

• Milling head swivel range: 180 x 1 degree

• Tool holder: SK 50 DIN 69871

• Speed range: 36 – 4,000 rpm

o Short-term: 36 – 6,000 rpm

Automatic Tool Changer

• Tool magazine for 48 tools

Clamping Plate

• Clamping surface: 4,000 x 1,500 mm

Chip Conveyor

• Fork length: 4,000 mm

Coolant System

• Tank capacity: 500 l

Splash and Chip Protection

• One-sided, with 2 manually sliding doors

Bedpfxjw I Rz Ho Afhecu

About the Company MBM

MBM Maschinenservice & Gebrauchtmaschinen GmbH is an independent specialist for SHW machine tools. Our main focus is on tool milling machines. Our services include, among others, spare parts delivery, on-site customer service, machine overhauls, and control system modernization.

Services:

- Used machines

- Spare parts

- Customer service

- Machine servicing

- Machine overhauls

- CNC control modernization

-----

_____

Used machine – used milling machine – used traveling column milling machine – orthogonal milling head – metalworking – tool milling machine – milling head – SHW machine – SHW spare parts – used milling machine – used cnc milling machine – used boring and milling machine – used metal milling machine – used metal mill – used metal machining center – used cnc mill – cnc milling machines – milling machinery – large part machining – cnc large part machining – milling – shw – PS5 – PS 5 – Powerspeed – SHW PSZ 5 – SHW Powerspeed – SHW Powerspeed 5 – PSZ 5 – Heidenhain – MBM milling machine – MBM machine – column-type milling machine

Listing

Bächingen an der Brenz

Bächingen an der Brenz

6,758 km

Travelling column milling machine

vaumatecVBF 1500 H

Call

Condition: new, Year of construction: 2025, functionality: fully functional, travel distance X-axis: 1,500 mm, travel distance Y-axis: 1,000 mm, travel distance Z-axis: 700 mm, spindle speed (max.): 8,000 rpm, Traveling column machine

New machine

Work table clamping area mm 1500 x 1000

Table height mm 750

Number of T-slots 6

Size of T-slots DIN 650 mm 18

Travel paths

X-axis mm 1500

Y-axis mm 1000

Z-axis mm 700

Distance table top edge -

spindle bottom edge min/max. mm 150 / 850

Main spindle drive for speed 8000 min-1

AC motor, frequency controlled kW 16 at 44% ED

Speed range: min -1 15 – 8000

Torque at 44% ED Nm 104

constant up to min -1 1500

Feed drives

X-axis AC servo motor kW 3.5

Y-axis AC servo motor kW 2.0

Z-axis AC servo motor kW 3.5

Rapid traverse speeds (X/Y/Z): m/min. 30/30/20

Indirect position measuring system.

Accuracy

Positioning accuracy X, Y axis

to 1000 mm mm ± 0.0150

Repeatability X, Y axis mm ± 0.0075

Positioning accuracy Z axis mm ± 0.0150

Repeatability Z axis mm ± 0.0075

Tool magazine 24-way

- Tool positions 24

- Tool shaft (DIN 69871 / 69872) SK 40

Bcedpfx Afovwip Dohou

- Max. tool diameter mm 76

- Max. tool length mm 250

- Max. tool weight kg 8

Machine control Heidenhain TNC 620

Listing

Bächingen an der Brenz

Bächingen an der Brenz

6,758 km

Travelling column milling machine

DonauDanusys 1510 L

Call

Condition: refurbished (used), Year of construction: 2006, functionality: fully functional, machine/vehicle number: 65039, travel distance X-axis: 1,500 mm, travel distance Y-axis: 1,000 mm, travel distance Z-axis: 700 mm, spindle speed (max.): 8,000 rpm, Traveling column machine

Generally overhauled 2023

Work table clamping area mm 1500 x 1000

Bjdpfx Afswv Nl Uohecu

Table height mm 750

Number of T-slots 6

Size of T-slots DIN 650 mm 18

Travel paths

X-axis mm 1500

Y-axis mm 1000

Z-axis mm 700

Distance table top edge -

spindle bottom edge min/max. mm 150 / 850

Main spindle drive for speed 8000 min-1

AC motor, frequency controlled kW 16 at 44% ED

Speed range: min -1 15 – 8000

Torque at 44% ED Nm 104

constant up to min -1 1500

Feed drives

X-axis AC servo motor kW 3.5

Y-axis AC servo motor kW 2.0

Z-axis AC servo motor kW 3.5

Rapid traverse speeds (X/Y/Z): m/min. 30/30/20

Indirect position measuring system.

Accuracy

Positioning accuracy X, Y axis

to 1000 mm mm ± 0.0150

Repeatability X, Y axis mm ± 0.0075

Positioning accuracy Z axis mm ± 0.0150

Repeatability Z axis mm ± 0.0075

24-way tool magazine

mounted on the right-hand side of the traveling column

- Tool positions 24

- Tool shaft (DIN 69871 / 69872) SK 40

- Max. tool diameter mm 76

- Max. tool length mm 250

- Max. tool weight kg 8

Machine control Heidenhain iTNC530 optional 620

Listing

Bächingen an der Brenz

Bächingen an der Brenz

6,758 km

Travelling column milling machine

DonauDanusys 2910 L

Call

Condition: good (used), Year of construction: 2003, functionality: fully functional, travel distance X-axis: 2,900 mm, travel distance Y-axis: 1,000 mm, travel distance Z-axis: 700 mm, spindle speed (max.): 8,000 rpm, Work table

Clamping surface mm 3000 x 1000

Table height mm 750

Number of T-slots 6

Size of T-slots mm 18

Travel distance

X-axis mm 2900

Y-axis mm 1000

Z-axis mm 700

Distance top edge of table - bottom edge of spindle

Spindle lower edge min/max. mm 150 / 850

Main spindle drive for speed 8000 min-1

AC motor, frequency-controlled kW 16 at 44% duty cycle

Speed range: min -1 15 - 8000

Torque at 44% ED Nm 96

constant up to min -1 1500

Feed drives

X-axis AC servo motor kW 3.5

Y-axis AC servo motor kW 2.0

Z-axis AC servo motor kW 3.5

Rapid traverse speeds (X/Y/Z): m/min. 30/30/20

Indirect measuring system.

Positioning accuracy

Positioning accuracy X-,Y-axis

to 1000 mm mm ± 0.0150

Repeat accuracy X-, Y-axis mm ± 0.0075

Positioning accuracy Z-axis mm ± 0.0150

Repeat accuracy Z-axis mm ± 0.0075

Tool magazine 2x 24-fold

Design as disk magazine

- Tool positions 16

- Tool shank (DIN 69871 / 69872) SK 40

- Max. tool diameter Tool diameter mm 76

- Max. Tool length mm 300

- Max. Tool weight kg 8

Machine control Heidenhain TNC 426

Splash guard cladding

Covering of the entire work area, designed as partial area protection in accordance with the valid guidelines of the German accident prevention regulations (UVV) and the European standard

EN 12417, with manually operated work area door including electrical protection and interlock. Machine door with polycarbonate glazing.

30 bar high-pressure coolant unit (IKZ)

for the use of tools with internal coolant supply,

switchable to 19 liters/min at 30 bar or 19 liters/min at 15 bar

complete with separate paper band filter.

Internal cooling is also possible with air

Clean tank capacity l 500

Degree of filtration my 30

Filter capacity l/min. 120

Hinged belt chip conveyor

instead of the chip collection tray with integrated coolant tank,

ejecting to the right

Discharge width approx. mm 300

Discharge height approx. mm 1050

incl. coolant system

Tank capacity liters approx. 150

Delivery rate l/min. 30

Pump capacity bar 2.0

HR 410 HEIDENHAIN hand-held control unit

External hand-held control unit with built-in electronic handwheel,

connected to the machine via cable,

for manual movement of the axes, with emergency stop button

Grease - central lubrication

documentation

Operating and programming instructions

Hydraulic and pneumatic diagram

Circuit diagram

Bedjw E Ey Hepfx Afhjcu

Test log

Listing

Germany

Germany

6,760 km

Travelling column milling machine

SORALUCEFP 6000

Call

Condition: excellent (used), Year of construction: 2009, x-travel 6000 mm

y-travel 2100 mm

z-travel 1500 mm

control HEIDENHAIN iTNC 530

feed 2- 20 m/min

spindle turning speed range 20 -4000 U/min

table dimension - longitudinal 7000 mm

table dimension - cross 2000 mm

total power requirement 79 kW

weight of the machine ca. 55 t

dimensions of the machine ca. 15 x 7 x 4,6 m

The SORALUCE FP6000 is in very good condition.

accessories as option:

# clamping angle: 5'000.-€

# Clamping cube: 2'000.-€

# Div. tools & workbench: 2'000.-€

Description:

- CNC control: HEIDENHAIN ITNC 530

Orthogonal milling head:

- Tool holder: ISO 50, DIN69871 AD

- Automatic tool clamping: Clamping force 20,000 N

- Indexing accuracy / repeatability: ± 3 sec. == ± 0.002 mm

- Tightening bolt: DIN 69872 form A

- Number of swivel positions: 1 x 1 ° milling head ( 360 positions rear plane,

270 positions front plane)

270 positions front plane)

- Diameter spindle bearing: 90

- Sealing air: 0,7 bar

Main drive:

- Drive type: three-phase motor

- Drive power: 100 % ED 32 kW

spindle:

- Spindle speed: 20 - 4000 rpm

- Full power from: 340 rpm

- Torque at 32 kW/S1: 910 Nm

- Speed control: 2 ranges infinitely variable via star/delta connection

Rapid traverse: max. 35000 mm/min

Bedpfx Afjvwgl Ajhscu

Listing

La Grand-Croix

La Grand-Croix

7,203 km

MOBILE MOUNTING MILL

TOS KUŘIMFraiseuse TOS FFQ 100 KR/A 14

Call

Condition: excellent (used), Year of construction: 1998, CN Heidenhain TNC 430 PA

Maximum spindle torque: 900 Nm

Maximum feed force in the X, Y, Z axes: 25,000 N

Maximum workpiece weight: 2,500 kg (at 1 m table length)

Table dimensions: 1,000 × 14,000 mm

Number of T-slots in the table: 7

T-slot width × spacing: 22H7 × 140 mm

Longitudinal travel (X): 12,000 mm

Cross travel (Y): 1,000 mm

Vertical travel (Z): 1,500 mm

Horizontal spindle:

Minimum distance between the horizontal spindle axis and table surface: 275 mm

Maximum distance between the horizontal spindle axis and table surface: 1,775 mm

Vertical spindle:

Minimum distance between the vertical spindle face and the table: 50 mm

Maximum distance between the vertical spindle face and the table: 1,550 mm

Spindle taper: ISO 50

Spindle diameter: 85 mm

Tool clamping force in the spindle: 16,500 N

Main machine dimensions:

Length: 17,850 mm

Width: 5,640 mm

Width with enclosure: 6,720 mm

Height: 4,350 mm

Bcjdpfxsxdwkfo Afhou

Floor space required: 73 m²

Total machine weight: approx. 34,000 kg

Electrical cabinet weight: approx. 820 kg

Mains voltage: 50 V (3 × 400)

Total machine power: 100 kVA

Fuses to be provided by the customer outside the machine for 400 V

Hydraulic unit weight without oil: 150 kg

Listing

Ellwangen (Jagst)

Ellwangen (Jagst)

6,769 km

Travelling column milling machine

SHWUF 6 Doppelständer X = 22.000 mm

Call

Condition: excellent (used), travel distance X-axis: 22,000 mm, travel distance Y-axis: 1,500 mm, travel distance Z-axis: 2,600 mm, table length: 22,000 mm, table width: 2,000 mm, rotary table diameter: 2,000 mm, Double-column milling machine

Technical Data

Travel paths per machine

• X-axis (bed): 22,000 mm

• Y-axis (vertical): 2,600 mm

• Z-axis (spindle carrier horizontal): 1,500 (1,200) mm

Control

• CNC control: Heidenhain TNC 430

Automatic tool changer

• Tool robot

• 90 magazine positions

Universal milling head in orthogonal design

• Swivel range toolholder: 360 x 1 degree

• Swivel range milling head: 180 x 1 degree

• Tool holder: SK 50 DIN 69871

• Speed: 3,200 rpm

2x chip conveyors

• Discharge height above floor: 1,250 mm

• Feed length: 24,000 mm

Table field

• Clamping area: 22,000 x 2,000 mm

Rotary table

• Clamping area: diameter 2,000 mm

About us:

Bedpfxewi Iaqo Afhjcu

MBM Maschinenservice & Gebrauchtmaschinen GmbH is an independent specialist for SHW machine tools. Our main focus is on tool milling machines. Our services include, among others, spare parts supply, on-site customer service, machine overhauls as well as control system upgrades.

Services:

- Used machines

- Spare parts

- Customer service

- Machine service

- Machine overhauls

- Control system modernization

_____ _____ _____

Used machine - used milling machine - used travelling column milling machine - orthogonal milling head - metalworking - tool milling machine - milling head - SHW machine - SHW spare parts - used milling machine - used milling machine (alt. spelling) - used CNC milling machine - used drill-milling machine - used metal milling machine - used metal mill - used metal milling machine - used CNC milling machine - CNC milling machines - CNC milling machines - milling machine - large part machining - large part machining (alt. spelling) - large part machining - CNC large part machining - milling - shw - uf6 - uf 6 - Uniforce - SHW UF - SHW Uniforce - SHW Uniforce 6 - UFZ 6 - UFZ6L - UFZ 6 L - Heidenhain - MBM milling machine - MBM machine - column milling machine

Trust Seal

Dealers certified through Machineseeker

Listing

Ellwangen (Jagst)

Ellwangen (Jagst)

6,769 km

Travelling column milling machine

SHWUniForce 6 X = 10.000 mm

Call

Condition: excellent (used), functionality: fully functional, travel distance X-axis: 10,000 mm, travel distance Y-axis: 1,500 mm, travel distance Z-axis: 2,600 mm, table length: 10,000 mm, table width: 2,000 mm, Travelling Column Milling Machine

Bjdpfx Aswuy Nbjfhjcu

Technical Specifications

Travel Axes

• X-axis (bed): 10,000 mm

• Y-axis (vertical): 2,600 mm

• Z-axis (horizontal ram): 1,500 (1,200) mm

Control

• CNC control: Heidenhain TNC 430

Automatic Tool Changer

• Tool robot

• 90 magazine slots

Universal Milling Head in Orthogonal Design

• Swivel range tool holder: 360 x 1 degree

• Swivel range milling head: 180 x 1 degree

• Tool holder: SK 50 DIN 69871

• Spindle speed: 3,200 rpm

Chip Conveyor

• Discharge height above floor: 1,250 mm

• Feed length: 10,000 mm

Table

• Clamping area: 10,000 x 2,000 mm

About us:

MBM Maschinenservice & Gebrauchtmaschinen GmbH is an independent specialist for SHW machine tools. Our core business focuses on tool milling machines. Our services include spare parts delivery, on-site customer service, machine overhauls, and CNC control upgrades.

Services:

- Used machines

- Spare parts

- Customer service

- Machine service

- Machine overhauls

- Control modernization

_____ _____ _____

Used machine - used milling machine - used travelling column milling machine - orthogonal milling head - metalworking - tool milling machine - milling head - SHW machine - SHW spare parts - used milling machine - used cnc milling machine - used boring milling machine - used metal milling machine - used metal mill - used metal milling machine - used cnc mill - cnc milling machines - milling machine - large workpiece machining - cnc large part machining - milling - shw - uf6 - uf 6 - Uniforce - SHW UF - SHW Uniforce - SHW Uniforce 6 - UFZ 6 - UFZ6L - UFZ 6 L - Heidenhain - MBM milling machine - MBM machine - column milling machine

Listing

Ellwangen (Jagst)

Ellwangen (Jagst)

6,769 km

Traveling column milling machine / Heidenhain 530

SHWUniForce 6 X = 8.000mm

Call

Condition: excellent (used), travel distance X-axis: 8,000 mm, travel distance Y-axis: 2,600 mm, travel distance Z-axis: 1,600 mm, rapid traverse X-axis: 20 m/min, rapid traverse Y-axis: 24 m/min, rapid traverse Z-axis: 24 m/min, feed rate X-axis: 20 m/min, feed rate Y-axis: 24 m/min, feed rate Z-axis: 24 m/min, spindle speed (max.): 3,200 rpm, rotational speed (max.): 3,200 rpm, pivoting range: 360 °, year of last overhaul: 2022, coolant supply: 16 bar, ejection height: 1,250 mm, tank capacity: 800 l, Technical Specifications

Travel Paths

• X-axis (bed): 8,000 mm

• Y-axis (vertical): 2,600 mm

• Z-axis (headstock horizontal): 1,600 mm

Control System

• CNC control: Heidenhain iTNC 530

Feed Rate

• Y- and Z-axis continuously adjustable from: 2 – 24,000 mm/min

• X-axis continuously adjustable from: 2 – 20,000 mm/min

Universal milling head with orthogonal design

• Milling head swivel range: 360 x 1 degree

• Milling head swivel range: 180 x 1 degree

• Tool holder: SK 50 DIN 69871

• Speed: 3,200 rpm

Chip Conveyor

• Ejection height above floor: 1,250 mm

• Feed length: 8,000 mm mm

• Feed width: 350 mm

Coolant system

• Paper belt filter system

o Tank capacity: 800 l

o Pump capacity on the machine: 16 bar

o Approx. 32 l/min

Year of manufacture: 2005

• 2016: General overhaul of the headstock unit

• 2022: General overhaul of the milling head

Bodpfxjwfdale Afhscu

About us:

MBM Maschinenservice & Gebrauchtmaschinen GmbH is an independent specialist for SHW machine tools. Our focus is on tool-milling machines. Our services include spare parts deliveries, on-site customer service, machine overhauls, and control system upgrades.

Services:

- Used machines

- Spare parts

- Customer service

- Machine service

- Machine overhauls

- Control system modernization

_____ _____ _____

Used machine - used milling machine - used traveling column milling machine - orthogonal milling head - metalworking - tool milling machine - milling head - SHW machine - SHW spare parts - used milling machine - used milling machine - used CNC milling machine - used drilling and milling machine - used metal milling machine - used metal milling machine - used metal milling machine - used CNC milling machine - CNC milling machines - CNC milling machines - milling machine - large-part machining - large-part machining - large-part machining - CNC large-part machining - milling - SHW - UF6 - UF 6 - Uniforce - SHW UF - SHW Uniforce - SHW Uniforce 6 - UFZ 6 - UFZ6L - UFZ 6 L - Heidenhain - MBM milling machine - MBM machine - column milling machine

Listing

Ellwangen (Jagst)

Ellwangen (Jagst)

6,769 km

Travelling column milling machine

SHWUniForce 6 X = 12.000 mm + Rundtisch

Call

Condition: excellent (used), functionality: fully functional, travel distance X-axis: 12,000 mm, travel distance Y-axis: 1,500 mm, travel distance Z-axis: 2,600 mm, table length: 12,000 mm, table width: 2,000 mm, Travelling Column Milling Machine

Technical Specifications

Travel ranges

• X-axis (bed): 12,000 mm

• Y-axis (vertical): 2,600 mm

• Z-axis (spindle head horizontal): 1,500 (1,200) mm

Bcsdpjwuy Udjfx Afheu

Controller

• CNC control: Heidenhain TNC 430

Automatic tool changer

• Tool robot

• 90 magazine positions

Universal milling head in orthogonal design

• Swivel range, milling head mount: 360 x 1 degree

• Swivel range, milling head: 180 x 1 degree

• Tool interface: SK 50 DIN 69871

• Spindle speed: 3,200 rpm

Chip conveyor

• Discharge height above floor: 1,250 mm

• Conveying length: 12,000 mm

Table area + rotary table

• Clamping surface: 13,000 x 2,000 mm, including rotary table with a clamping surface of 2,000 mm

About us:

MBM Maschinenservice & Gebrauchtmaschinen GmbH is an independent specialist for SHW machine tools. Our main focus is on tool milling machines. Our services include, among others, spare parts supply, on-site customer service, machine overhauls, as well as control retrofits.

Services:

- Used machines

- Spare parts

- Customer service

- Machine service

- Machine overhauls

- Control retrofits

_____ _____ _____

Used machine – used milling machine – used travelling column milling machine – orthogonal milling head – metalworking – tool milling machine – milling head – SHW machine – SHW spare parts – used milling machine – cnc milling machine used – drill milling machine used – used metal milling machine – metal mill used – used metal milling machine – used cnc mill – cnc milling machines – large part machining – cnc large part machining – milling – SHW – UF6 – UF 6 – Uniforce – SHW UF – SHW Uniforce – SHW Uniforce 6 – UFZ 6 – UFZ6L – UFZ 6 L – Heidenhain – MBM milling machine – MBM machine – column milling machine

Listing

Ellwangen (Jagst)

Ellwangen (Jagst)

6,769 km

Travelling column milling machine

SHWPowerSpeed 5 - Heidenhain iTNC 530

Call

Condition: reconditioned (used), travel distance X-axis: 10,000 mm, travel distance Y-axis: 1,300 mm, travel distance Z-axis: 2,100 mm, rapid traverse X-axis: 30 m/min, rapid traverse Y-axis: 30 m/min, rapid traverse Z-axis: 30 m/min, feed rate X-axis: 30 m/min, feed rate Y-axis: 30 m/min, feed rate Z-axis: 30 m/min, spindle speed (max.): 6,000 rpm, spindle speed (min.): 36 rpm, rotational speed (max.): 6,000 rpm, tank capacity: 1,200 l, SHW Powerspeed 5

Travel paths

• X-axis (bed): 10,000 mm

• Y-axis (headstock): 1,300 mm

• Z-axis (vertical): 2,100 mm

Control

• CNC control: Heidenhain iTNC 530

Feed rate

• X, Y and Z axes: 30,000 mm/min

• Acceleration: 3.5 m/s²

Universal milling head in orthogonal design

• Milling head holder swivel range: 360 x 1 degree

• Milling head swivel range: 180 x 1 degree

• Tool holder: SK 50 DIN 69871

• Speed range: 36 - 6,000 rpm

Chip conveyor

• Feed length: 10,000 mm

Coolant system

• Container capacity: 1,200 Liter

ATTENTION the images are comparison images

Bodpfx Afev Dhw Tshscu

About us:

MBM Maschinenservice & Gebrauchtmaschinen GmbH is an independent specialist for SHW machine tools. Our main focus is on tool milling machines. Our services include spare parts deliveries, on-site customer service, machine overhauls and control system modernizations.

Services:

- Used machines

- Spare parts

- Customer service

- Machine service

- Machine overhauls

- Control system modernization

_____

Used machine - used milling machine - used traveling column milling machine - orthogonal milling head - metalworking - tool milling machine - milling head - SHW machine - SHW spare parts - used milling machine - used milling machine - used CNC milling machine - used drilling and milling machine - used metal milling machine - used metal milling machine - used metal milling machine - used CNC milling machine - CNC milling machines - CNC milling machines - milling machine - large part machining - large part machining - large part machining - CNC large part machining - milling - shw - PS5 - PS 5 - Powerspeed - SHW PSZ 5 - SHW Powerspeed - SHW Powerspeed 5 - PSZ 5 - PSZ 5 - Heidenhain - MBM milling machine - MBM machine - column milling machine

We make the search easier for you

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used travelling column milling machines (108)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

- Automatic Milling Machine

- Bed Type Milling

- Bed Type Milling Machine

- Double Column

- Double Column Mill

- End Mill Machine

- German

- Manual Mill

- Milling Center

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month