Used Milling Center for sale (19,973)

Sort results

- Lowest price Highest price

- Newest listings Oldest listings

- Shortest distance Farthest distance

- Newest year of manufacture Oldest year of manufacture

- Latest update Oldest update

- Manufacturer A to Z Manufacturer Z to A

- Relevance

- Lowest price

- Price

- Highest price

- Price

- Newest listings

- Release date

- Oldest listings

- Release date

- Shortest distance

- Distance

- Farthest distance

- Distance

- Newest year of manufacture

- Year of construction

- Oldest year of manufacture

- Year of construction

- Latest update

- Update

- Oldest update

- Update

- Manufacturer A to Z

- Manufacturer

- Manufacturer Z to A

- Manufacturer

- designation from A to Z

- Description

- designation from Z to A

- Description

- Model from A to Z

- Model

- Model from Z to A

- Model

- Lowest reference

- Ref.No.

- Highest reference

- Ref.No.

- Shortest runtime

- Runtime

- Longest duration

- Runtime

- Relevance

- Relevance

Listing

Freiburg im Breisgau

Freiburg im Breisgau

6,942 km

CNC turning and milling center

SpinnerTC300-52

Call

Condition: excellent (used), Year of construction: 2014, operating hours: 43,000 h, functionality: fully functional, For sale is a high-precision CNC turning and milling center Spinner TC300-52, manufactured in 2014. The machine is in very well-maintained condition and was primarily used for prototype and small batch production. It has never been subjected to heavy-duty, maximum-load 3-shift continuous operation, which is reflected in its excellent mechanical condition. The machine is under power and ready for demonstration at the Freiburg location! The spindle hours are significantly lower than the total operating hours!

This machine is sold including a comprehensive tooling package and a wide range of tool holders, numerous collets for main and sub spindle, as well as several reduction sleeves. The tooling and accessories alone (including numerous driven double tool holders) have a new replacement value of approximately €15,000 to €20,000. This makes the machine the ideal solution for companies aiming to start highly complex production immediately, without lengthy additional investments.

Documentation: The original order confirmation, detailing the complete equipment specification, is available for inspection.

- Location: 79115 Freiburg (DE)

- Availability: The machine is under power, available for demonstration, and can be delivered immediately.

- Scope of delivery: Includes tool holders, collets, and complete documentation.

• Year of manufacture: 2014

• Control: Siemens 840D-SolutionLine with 15" color display and ShopTurn (conversational programming)

• Working area: X 180 mm / Z 450 mm / Y +/- 40 mm

• Spindles: main spindle (5,000 rpm) & sub spindle (7,000 rpm), both liquid-cooled motor spindles

• Tool turret: 12 stations (VDI25), all driven (up to 6,000 rpm)

• Bar capacity: up to Ø 52 mm

• Coolant package: Switchable 15 bar high-pressure pump for internally cooled tools

• Measurement systems: Integrated tool probe arm for quick setup

• Workholding: Collet chucks from SMW Autoblok (185E and 164E) incl. reduction sleeves

• Safety & convenience: Clamping force regulation via differential pressure on the sub spindle (ideal for delicate parts), parts catcher with catch box, and hinged belt chip conveyor

Hnodpfsx Sr Uwjx Adweg

• Precision guide concept: Unlike standard machines, Spinner utilizes hardened and ground slideways on all axes, providing superior vibration damping, excellent surface finishes, and longer tool life

• Fully equipped (All-Inclusive): The machine features a Y-axis (+/- 40 mm) and a full-fledged sub spindle, enabling complete machining of complex parts in a single setup

• Advanced measurement technology: Absolute measuring systems (glass scale in X1) eliminate the need for referencing after startup

Listing

Germany

Germany

6,760 km

CNC turning and milling center

DOOSANPuma MX2100 LST

Call

Condition: used, Year of construction: 2014, CNC turning and milling center (9 axes) with Y-axis, B-axis, sub-spindle, and tool turret

CNC control FANUC 31iTA with Manual Guide i

Swing diameter over bed: 750 mm

Swing diameter over cross slide: 600 mm

Collision-free turning diameter: 210 mm

Max. turning diameter main spindle: 540 mm

Max. turning length: 1,520 mm

Main spindle left and right (sub-spindle)

Chuck diameter: 210 mm

Spindle bore: 76 mm

Bar capacity: 66 mm

Speed range up to: 5,000 rpm

Max. torque: 318 Nm

Turning/milling spindle (swivel head, B-axis)

Speed range up to: 12,000 rpm

Torque: 81 Nm

Drive power: 18.5 kW

Positioning: 0.001°

Swivel range: 240° (+120°)

Hnodox Hy R Njpfx Adwjg

Tool magazine ATC

Number of magazine stations: 40

Tool holder: CAPTO C6

Lower turret

Tool stations: 12

Drill holder diameter: 40 mm

Tool shank cross-section: 25x25 mm

Tool holder type: BMT 55P

Motor drive power: 5.5 kW

Tool speed: 5,000 rpm

- Chip conveyor

- Parts removal with conveyor belt

- Tool measurement arm

- Internal coolant supply through sub-spindle

- Chuck cleaning

- Air/water through turret

- Knoll compact filter unit

- Automatic workpiece measurement

Listing

Hattingen

Hattingen

6,987 km

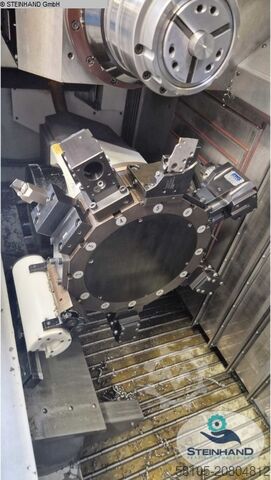

CNC Turning- and Milling Center

SPINNERTTS 65 Triplex

Call

Condition: used, Year of construction: 2015, turning diameter 250 mm

turning length 600 mm

control FANUC Series 31i-Model A

travel -x axis 180 mm

travel -y axis +/-45 mm

- - - - - Main spindle - - - - - - - - - - -

turning speeds 0 - 5.000 U/min

bar capacity 65 mm

--- Subspindle --- - - - - - -

turning speeds 0 - 7.000 U/min

bar capacity 42 mm

--- upper turret 1 --- - - - - - -

numbers of positions in the tool changer 12

tool taper BMT 45

Number of axles X1 / Y1 / Z1 St.

Hsdpfx Adsx I Shpowong

Tools speed 8.000 U/min

--- upper turret 2 --- - - -

numbers of positions in the tool changer 12

tool taper BMT 45

Tools speed 8.000 U/min

Number of axles X3 /Y3 / Z3 St.

--- lower turret 3 --- - - -

numbers of positions in the tool changer 12

tool taper BMT 45

Number of axles X2 / Z2 St.

Tools speed 8.000 U/min

CNC Turning- and Milling Center | SPINNER - TTS 65 Triplex equipped with a main spindle and a sub-spindle, each including a C-axis, three triplex turrets designed for driven tools, as well as a bar feeder (Top Automazioni X-Files-S Series 3000, SX version).

The machine has only 3.500h processing time hours.

The machine is in good condition and can be inspected under power.

Please refer to further technical details in the attachement of the offer.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

#Tags: TTS65Triplex | TTS 65Triplex | TTS-65-Triplex | TTS-65 Triplex

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month

Listing

Germany

Germany

6,955 km

CNC Turning- and Milling Center

NILES-SIMMONSN30 - 3MC-2500

Call

Condition: used, Year of construction: 2007, turning diameter 470 mm

turning length 2500 mm

control Siemens Sinumerik 840 D

work height max. 1300 mm

swing diameter over bed slide 750 mm

swing over bed 780 mm

diameter of quill 160 mm

taper bore MK 5

tool numbers 48

weight of tools max. 15 kg

tool length - max. 500 mm

total power requirement 123 kVA

weight of the machine ca. 27 t

dimensions of the machine ca. 8,4 x 4,0 x 3,3 m

C-axis:

Hnedpfx Adow Rf Tijwog

- Speed range - 30 rpm

- Max. torque at rotary spindle (60% duty cycle) 930 Nm

- Positioning accuracy 0.005 degrees

Slide travel:

- X-axis 720 mm

- Z-axis 4072 mm

Rapid traverse:

- X-axis 18 m/min

- Z-axis 30 m/min

Feed rates:

- X-axis mm/min

- Z-axis - mm/min

Workpiece spindle:

- Spindle head according to DIN 55026: A 11

- Through bore: 123 mm

- Diameter in front bearing: 200 mm

- Oriented spindle stop: 0–359 degrees

Workpiece spindle drive with 2-stage gearbox:

- Drive power at 100/60% duty cycle: 37/45 kW

- Total speed range: 10–2,500 rpm

- Number of speed ranges: 2

- Speed range I: 10–775 rpm

- Speed range II: 20–2,500 rpm

- Max. torque at 60% duty cycle: 2,083 Nm (up to 186 rpm)

Equipment/accessories:

- Forkardt power chuck with one set of hard and soft jaws each

- Hydraulic steady rest

- Tailstock with center point

- Chip conveyor

- Coolant device

- 5 HSK 100 A holders

- Technical documentation

Listing

Düsseldorf

Düsseldorf

7,016 km

CNC turning and milling center

EMCOEMCOTURN E 45

Call

Condition: like new (used), Year of construction: 2018, Technical Data:

• Swing diameter over cross slide: 430 mm (max. turning diameter 220 mm)

• Turning length: max. 670 mm

• Spindle bore (clearance diameter): 45 mm

• HS spindle interface DIN 55026 A2-5

• Main drive power: 13 kW

• Max. torque: 78 (100) Nm

• Speed range: 0–6300 rpm

• Counter spindle interface: DIN 55026 A2-4

• Number of tools: 12 driven tools, max. speed: 0–6000 rpm

• Tool holder: VDI 25

• Pressure boost station E45 for central coolant system; centrifugal pump 14 bar; lifting pump min. 1.5 bar

• Chip conveyor: hinge belt conveyor, discharge height 1200 mm

• Swing loader Emcoturn E45 with loading and unloading system; 2-finger parallel gripper / 90° rotating module

• Belt conveyor for RT parts feeding: length 1300 mm / width 567 mm; chain pitch 27.1 mm (1800L)

• Control: Siemens 828 D

⸻

• Connected load: approx. 46 kVA

• Voltage: 400 V / 50 Hz

Hedpfjwl Uu Hsx Adweng

• Weight: approx. 4,300 kg

• Space requirement: approx. 15 m²

Listing

Neuss

Neuss

7,023 km

CNC turning and milling center

SAMSUNG SMECSAMSUNG SMEC PL-60L

Call

Condition: used, SAMSUNG SMEC PL-60L Ø1,030 x 3,200 mm / 2016 Model

Machining Capacity / Fanuc Oi TD CNC Controller

• Swing over bed: Ø 1,030 mm (32 inch hydraulic chuck)

• Swing over cross slide: Ø 800 mm

• Maximum turning diameter: 530 mm

• Maximum machining diameter: Ø 900 mm

Hjdjx Scpropfx Adwong

• Maximum turning length: 3,200 mm (Ø 45~310 mm with hydraulic steady rest)

• Maximum chuck machining diameter: 139.5 mm

Axis Travel

• X-axis travel: 470 mm

• Z-axis travel: 3,270 mm

Spindle

• Spindle bore: 1,500 mm

• Spindle nose size: 21"

• Spindle nose type: A2-15

• Spindle through hole diameter: Ø152 mm

Turret (Standard)

• Number of tool stations: 12 (Standard)

• Tool shank size: □32 mm

• Boring bar shank size: Ø80 mm

Tailstock

• Tailstock travel: 3,270 mm

• Quill diameter: Ø180 mm

• Tailstock taper: MT-6 (built-in)

• Tailstock stroke: 150 mm

Power & Installation

• Power requirement: 65 kVA

• Machine dimensions (L × W): 7,400 × 2,760 mm

• Machine weight: 22,000 kg

Listing

Bremen

Bremen

6,883 km

CNC turning and milling center

TRAUBTNX 65/42 DGY

Call

Condition: good (used), Year of construction: 2012, functionality: fully functional, Description follows

Hjdpfx Adex A Hdfeweng

Listing

Schwindegg

Schwindegg

6,615 km

CNC turning and milling center

GildemeisterCTX-500 E

Call

Condition: used, Year of construction: 1998, operating hours: 40,519 h, functionality: fully functional, machine/vehicle number: 315546, turning length: 1,000 mm, turning diameter: 440 mm, spindle speed (max.): 3,600 rpm, spindle bore: 80 mm, travel distance X-axis: 220 mm, travel distance Z-axis: 1,000 mm, type of input current: three-phase, bar passage: 72 mm, total height: 1,900 mm, total length: 5,560 mm, total width: 2,190 mm, overall weight: 7,500 kg, We are offering this used Gildemeister CTX-500 E CNC turning and milling center, year of manufacture 1998.

Machine type: CTX-500 E

Serial number: 315546

Year of manufacture: 1998

Well-maintained machine in original paint.

Accessories:

Chip conveyor

Exhaust air filter

Hnsdpox Rhttjfx Adwog

3 driven tools

Various tool holders

Various jaws

If you have any questions or require further information, please feel free to send us a message or call us.

Listing

Alblasserdam

Alblasserdam

7,161 km

CNC turning and milling center

Cnc lathe Hyundai WIAL200Y

Call

Condition: used, Year of construction: 2012, functionality: fully functional, machine/vehicle number: G3169-0110, turning length: 530 mm, turning diameter: 420 mm, spindle speed (min.): 20 rpm, spindle speed (max.): 4,000 rpm, spindle bore: 65 mm, travel distance X-axis: 220 mm, travel distance Y-axis: 80 mm, travel distance Z-axis: 550 mm, overall weight: 4,700 kg, turning diameter over bed slide: 800 mm, HYUNDAI WIA L200SY CNC TURNING CENTER

Hnedpfx Adox I A Hcjweg

Year: 2012 | Fanuc 18i-TB CNC Control

SN: G3169-0110

• 5-Axis CNC Turning Center – Hyundai WIA L200SY

• Main Chuck: 8″ | Sub Spindle: 5″

• Live Tooling & Y-Axis + C-Axis indexing

• Max Turning Diameter: approx. 419–420 mm / 16.5″

• Max Turning Length: approx. 520–530 mm / ~20.5–20.9″

• Swing Over Bed: approx. 800 mm / 31.5″

• X Travel: approx. 220 mm / 8.7″

• Z Travel: approx. 550 mm / 21.7″

• Y Travel: approx. 80 mm / 3.1″

• Max Spindle Speed: up to 4,000 rpm

• Main Spindle Power: ~20 HP (~15 kW)

• Sub Spindle Speed up to 6,000 rpm

• C-Axis indexing: 0.001° possible

• Tool Stations: approx. 12

• Coolant system and chip conveyor included

• Approx. Dimensions: 120″ × 68″ × 80″

• Approx. Weight: ~10,500 lbs (~4,760 kg)

NOTE: MACHINE WAS REMOVED FROM GOOD WORKING CONDITION 2 YEARS AGO. PLANNED TO PUT BACK IN SERVICE BUT SELLER WILL NO LONGER BE DOING MACHINING.

Listing

Hilden

Hilden

7,005 km

CNC Turning- and Milling Center

NILES-SIMMONSN20-2 MC

Call

Condition: used, Year of construction: 2013, turning diameter . mm

turning length 2000 mm

control Siemens 840 D sl

mainspindle: turning speed max. 3800 1/min

mainspindle: torque max. 1200 Nm

diameter of quill 140 mm

center point MK6

quill power 5 - 30 kN

feed rate Z-axis mm/min

rapid traverse Z-axis 40 m/min

feed rate X-axis - mm/min

Hsdovu E R Sspfx Adwsng

rapid traverse X-axis 25 m/min

total power requirement 125 kW

weight of the machine ca. 20 t

The machine can still be inspected under power at the production plant.

The condition of the machine is good, the accuracy during turning operation

is very good.

The milling drive is not functional. A quotation from Niles for the repair

of the milling drive is available on request.

Including hydraulic steady rest.

Listing

Velbert

Velbert

6,998 km

CNC turning and milling center

DMG MORICLX 450 TC

Call

Condition: excellent (used), Year of construction: 2023, CNC Milling and Turning Center

Machine type: DMG Mori CLX 450 TC

Control: Siemens 840 D sl Operate Slimline

Year of manufacture: 2023

TECHNICAL DATA:

Max. turning length: 1,100 mm

Turning diameter: 400 mm

Main spindle: ISM 65

Speed range: 5,000 rpm

Drive power: 14 / 17 kW

Torque: 275 / 345 Nm

Spindle nose: A2-8

Bar capacity: 67 mm

C-axis

CNC spindle swiveling for milling and turning operations

Max. speed: 12,000 rpm

Drive power: 8.8 / 10.5 kW

Torque: 73 / 90 Nm

Tool holder: HSK 63

Tool positions: 60

Counter spindle: ISM 65

Spindle nose: A2-8

Max. speed: 5,000 rpm

Hodsx Ryw Repfx Adwsng

Drive power: 14 / 17 kW

Torque: 275 / 345 Nm

C-axis

X-axis: 750 mm

Y-axis: +/- 100 mm

Z-axis: 1,100 mm

B-axis: +/- 120 mm

Features:

Chip conveyor

Direct position measuring system

Chip flushing gun

3-jaw chuck: SMW-Autoblok BBD 250/78 mm

3-jaw chuck: SMW BBD 250/78 mm

Tailstock function on counter spindle

High-pressure pumps: 8 bar / 20 bar

Coolant tank: 600 l

Oil mist extraction

Probe: Renishaw RMP 40

Listing

Düsseldorf

Düsseldorf

7,016 km

CNC turning-drilling-milling center

KlaaßenSDM15-5

Call

Condition: ready for operation (used), Year of construction: 2019, functionality: fully functional, turning diameter: 1,500 mm, Versatile turning and machining center for full-scale turning and complex drilling and milling.

Turning diameter 1500 mm

Center distance 4500 mm

X travel 1000 mm

Y travel 350 mm

Z travel 5000 mm

- 4-track bed-type machine

- Powerful headstock with backlash-free C-axis

- Full-featured milling in 3 axes (Y-axis = 340 mm)

Hnedjwkqhgopfx Adwog

- Direct measuring system on each CNC axis

- Continuously adjustable motorized milling spindle

- Klaassen motorized milling spindle 37 kW/4000 rpm/330 Nm (S1)

- Automatic tool change for turning and milling tools

- Steady rests and tailstock fully traversable

- Internal milling head

- Grinding support

- Extensive range of accessories available

The machine has been regularly serviced and is in very good technical condition.

Technical drawings and parts lists are available for the machine's components and assemblies.

Documentation and technical data are available for all components of the machine.

Listing

Bremen

Bremen

6,883 km

CNC turning and milling center

TRAUBTNA 480

Call

Condition: used, Year of construction: 1987, operating hours: 80,678 h, functionality: fully functional, Description follows

Hjdpfx Aox A Hl Asdwjng

Listing

Ciserano

Ciserano

6,809 km

CNC turning and milling center

DOOSANPuma 280 LM

Call

Condition: good (used), Year of construction: 2008, Year: 2008

FANUC 0i Series Control

Swing over saddle: 500 mm

Bar capacity: 76 mm

Spindle size: 315 mm (12″)

Maximum turning diameter: 410 mm

Maximum turning length: 1030 mm

Swing diameter: 630 mm

Tailstock quill diameter: 100 mm

Tailstock quill stroke: 100 mm

Taper MT #5

Turret positions: 12 stations

Hnedsx Rrf Tjpfx Adwsg

Driven turret speed: 5000 rpm

Rapid traverse XZ: 20 x 24 m/min

Spindle motor power: 22 kW

Spindle nose: A2 #8

Spindle speed: 3500 rpm

Boring bar holder diameter: 50 mm

Tool dimensions: 25 x 25 mm

X-axis travel: 242 mm

Z-axis travel: 1100 mm

Machine dimensions: 3418 x 1670 x 1735 mm

Machine weight: 4700 kg

Listing

Hlavní město Praha

Hlavní město Praha

6,464 km

CNC turning and milling center

DoosanPuma TT 1800 SY

Call

Condition: used, Upper driven head with Y axis, lower driven head, twin spindles. Max. swing over bed: 300 mm. Max. swing over support: 230 mm. Max. swing over bed with upper head: 230 mm. Max. swing over bed with lower head: 230 mm. Max. turning length: 600 mm. Max. distance between the face of the right and left spindle: 980 mm. Milling range outside the turning axis via Y axis: 100 mm (+/-50 mm). Max. turned bar diameter (left spindle): 65 mm. Max. turned bar diameter (right spindle): 65 mm. Max. permissible workpiece weight without counter spindle (including chuck weight = 23 kg): 12 kg. Total weight: 7800 kg. Accessories: Feeder SS 2500, length 200-1525 mm.

Hnsdpfx Aox Np U Aedwjg

Listing

Hilden

Hilden

7,005 km

CNC Turning- and Milling Center

WFL-MILLTURNM100 MILLTURN / 6500

Call

Condition: used, Year of construction: 2010, longitudinal traverse (z-axis) 6870 mm

cross movement. (x-axis) 920 mm

centre distance 6500 mm

swing diameter over slide rest 900 mm

Control Siemens Sinumerik 840D

tool taper CAPTO C8

7352 mm

max. workpiece weight 9000 kg

tools in tool magazin 72

total power requirement 145 kW

weight of the machine ca. 47 t

dimensions of the machine ca. 11 x 3,2 x 3,5 m

Rotary spindle

-Spindle diameter - 320 mm

-Spindle bore - 245 mm

Main drive:

-Max. spindle speed - 1600 rpm

-Max. torque at the spindle - 4472 Nm

C-axis servo-controlled main spindle:

-Max. speed - 20 rpm

-Max. torque at the spindle - 3000 Nm

-Holding torque of the disc brake - 6000 Nm

Tailstock:

-Quill diameter - 180 mm

Hsdpsxzuvtsfx Adwsng

-Quill stroke - 200 mm

-Quill force (adjustable) - 5400 to 40000 N

Tool holder:

-AC drive power - 30 kW

-Max. spindle speed - 6000 rpm

-Max. torque at the spindle - 315 Nm

-Travel perpendicular to the X/Z plane (y-axis) - 500 mm [-200/+300]mm

-Milling spindle diameter in the front bearing - 100 mm

Equipment/accessories:

-with internal coolant supply

-chip conveyor

-paper belt filter system

-boring bar with device

-measuring equipment

-clamping sleeves

-tool holders

-spare parts

-technical documentation

Listing

Germany

Germany

6,760 km

CNC Turning- and Milling Center

DMG MORICTX Beta 1250 TC 4A

Call

Condition: used, Year of construction: 2013, Control Heidenhain iT Plus

Dimensions (L x W x H) 6,55 x 3,46 x 2,40 m

weight of the machine 14.500 kg

--> Technical details Operating hours: 43,506 h

Hnodpfsxpizgex Adweg

--> Spindle hours: 25,244 h

--> Spindle box left:

--> Chuck diameter: 315 mm

--> Spindle flange diameter: 1705 mm

--> Spindle bore: 104 mm

--> Spindle diameter in front bearing: 130 mm

--> Drive power (100% duty cycle): 25 kW

--> Drive power (40% duty cycle): 32 kW

--> Torque (100% duty cycle): 280 Nm

--> Torque (40% duty cycle): 360 Nm

--> Speed range: 0–5,000 rpm

--> Speed of C-axis: 2,000 rpm

--> Spindle box on the right:

--> Chuck diameter: 315 mm

--> Spindle flange diameter: 1,705 mm

--> Spindle bore: 87 mm

--> Spindle diameter in front bearing: 130 mm

--> Drive power (100% duty cycle): 25 kW

--> Drive power (40% duty cycle): 32 kW

--> Torque (100% duty cycle): 280 Nm

--> Torque (40% duty cycle): 360 Nm

--> Speed range: 2,000 rpm

--> Right spindle housing:

--> Chuck diameter: 315 mm

--> Spindle flange diameter: 1705 mm

--> Spindle bore: 87 mm

--> Spindle diameter in front bearing: 130 mm

--> Drive power (100% duty cycle): 25 kW

--> Drive power (40% duty cycle): 32 kW

--> Torque (100% duty cycle): 280 Nm

--> Torque (40% duty cycle): 360 Nm

--> Speed range: 2,000 rpm

--> Slide 1:

--> Longitudinal travel: 1,200 mm

--> Cross travel: 490 mm

--> Vertical travel Y: ±100 mm

--> Slide 2:

--> Longitudinal travel: 1,200 mm

--> Cross travel: 195 mm

--> Slide 3:

--> Longitudinal travel: 1,200 mm

--> Turning/milling spindle:

--> Tool holder: Capto C6

--> Spindle speed: 12,000 rpm

--> Drive power (100% duty cycle): 20 kW

--> Drive power (40% duty cycle): 22 kW

--> Torque (100% duty cycle): 79 Nm

--> Holding torque, locked: 1,000 Nm

--> Swivel range: ±110 degrees

--> Tool magazine:

--> Number of tools: 120

--> Max. tool length: 300 mm

--> Max. tool diameter: 80 mm

--> Max. tool weight: 7 kg

--> Tool carrier 2:

--> Number of tool stations: 12

--> Shank diameter according to DIN 69880: 40 mm

--> Number of driven tool stations: 12

--> Max. speed: 4,000 rpm

--> Max. power: 11.3 kW

Listing

Wishaw

Wishaw

7,699 km

CNC turning and milling center

MazakE-650H

Call

Condition: good (used), Year of construction: 2004, turning length: 2,000 mm, Model: E-650H

Control: Mazatrol 640M Pro

Year: 2004

Distance Between Centres: 2000mm

Swing Over Bed: 905mm

Machine With:

C Axis

Y Axis

Live Tooling/Milling

Hsdjxvyq Eepfx Adwong

B Axis

800mm Power Chuck

Manual Steady 375mm

Open Steady 600mm

Air Filer Mist

Listing

Cascina Faustina

Cascina Faustina

6,860 km

Cnc turning and milling center

SpinnerTC77 SMCY

Call

Condition: good (used), Year of construction: 2006, functionality: fully functional, The used SPINNER TC77 SMCY counterspindle Y-axis motorized cnc lathe is a robust CNC tilting lathe with ASA 8" size flat guideways, with BARUFFALDI automatic 2-speed gear-driven range change, equipped with a counterspindle and spindle both with "C" axis and a motorized Y-axis turret with 120mm travel (+60/-60 mm) VDI 50.

Completing the configuration is the FANUC i-series cnc with color lcd and Manual Guide i conversational programming, ethernet interface, RS 232 port and memory card for program entry, chip evacuation, 315mm BB 3-jaw hydraulic chuck, a set of motorized toolholders (10 pieces) and several fixed ones, and a large set of clamps.

Main features:

Maximum turning diameter 690 mm

Max. standard turning diameter 500 mm

Max. workpiece length 800 mm

Max. main spindle bar diameter 77 mm

Max. secondary spindle bar diameter 52 mm

Hjdpfjuizukex Adwong

Main spindle chuck self-centering 315mm

Secondary spindle chuck chuck 210mm

Max. x-axis travel 360mm

Max. Y-axis travel 120 mm (-55/+65)

Max. z-axis travel 980 mm

Main spindle ASA 8" 26kW main spindle up to 1030 Nm torque and max. 4000 rpm.

ASA 6" 18kW secondary spindle ASA 6" up to 113 Nm torque and rpm of maximum 4000 rpm.

12-position VDI 50 tool changer turret (rotating 4,000 rpm).

Machine weight: approx. 6,000 kg

Year of construction 2006, installed 2008, with about 5,800 working hours; "CE" compliant complete with manuals.

Listing

Savonlinna

Savonlinna

5,966 km

CNC turning and milling center

DMG MORIGMX 200

Call

Condition: good (used), Year of construction: 2004, operating hours: 4,900 h, functionality: fully functional, turning length: 1,070 mm, turning diameter over cross slide: 400 mm, turning diameter: 560 mm, spindle motor power: 37 W, spindle speed (max.): 4,500 rpm, Gildemeister GMX 200 Linear (2004)

KUKA KR 150-2 Robot (2004)

Automated Mill-Turn Production Cell

For sale: High-performance automated machining cell comprising a Gildemeister GMX 200 Linear mill-turn center and a KUKA KR 150-2 industrial robot. The system is engineered for efficient, flexible, and unmanned production operations.

CNC Lathe / Mill-Turn Center

Gildemeister GMX 200 Linear – Technical Specifications

General

Manufacturer: Gildemeister

Model: GMX 200 Linear

Year of manufacture: 2004

Machine type: CNC mill-turn center

Control system: Siemens Sinumerik 840D

Drive technology: Linear motors on X, Y, and Z axes

Turning

Maximum turning diameter: 560 mm

Turning diameter over cross slide: 400 mm

Maximum turning length: 1,070 mm

Bar capacity: 65 mm

Axes and Travels

X-axis travel: 485 mm

Y-axis travel: 160 mm

Z-axis travel: 1,070 mm

B-axis swivel range: ±110°

Main Spindle

Spindle speed: 5,000 rpm

Spindle power: 37 kW

Tool interface: HSK-A63

Milling

Milling spindle speed: 12,000 rpm

Tool holder: HSK-A63

Tool System

Number of tool positions: 48

Automatic tool changer

Equipment

Y-axis

B-axis milling unit

Linear motor technology

Chip conveyor

Central coolant system

Full CNC integration for robotic automation

Industrial Robot

KUKA KR 150-2 – Technical Specifications

General

Manufacturer: KUKA

Model: KR 150-2

Robot type: 6-axis industrial robot

Year of manufacture: 2004

Application: Part handling / automation

Load and Reach

Maximum payload: 150 kg

Maximum reach: 2,700 mm

Axes

Number of axes: 6

Axis Motion range

A1 ±185°

A2 −155° / +35°

A3 −120° / +158°

A4 ±350°

A5 ±125°

A6 ±350°

Axis Speeds

A1: 120 °/s

A2: 110 °/s

A3: 110 °/s

A4: 190 °/s

A5: 180 °/s

A6: 260 °/s

Accuracy

Repeatability: ±0.2 mm

Controller and Electrical

Controller: KUKA KRC2

Power supply: 3 × 400 V / 50 Hz

Installation

Mounting: Floor-mounted

Installation position: Freely programmable

Weight

Robot weight: 1,245 kg

Production Cell Advantages

- Turning and milling in a single setup

- Automated part loading and unloading

Hnjdpfx Adex Iflhoweg

- Suitable for serial production and unmanned operation

- High precision and productivity

- Ideal for CNC job shops and industrial manufacturing

📍 Location: Finland

🚚 Delivery: Transportation can be arranged

📄 Condition: Used

ℹ️ Note:

Technical specifications to be verified with the seller prior to purchase.

Listing

Karlsbad

Karlsbad

6,889 km

CNC turning and milling center

INDEXG 200 YB

Call

Condition: good (used), Year of construction: 1998, functionality: fully functional, turning length: 400 mm, turning diameter: 60 mm, spindle speed (max.): 6,000 rpm, overall weight: 4,800 kg, Equipment: documentation/manual, rotational speed infinitely variable, Main spindle Ø 60 mm

Counter spindle Ø 42 mm

2 turrets with 14 stations each

Milling spindle on upper turret

LNS Hydrobar – bar feeder

Hedpfx Aox Ez Ndsdwong

Trust Seal

Dealers certified through Machineseeker

Listing

L'Hospitalet de Llobregat

L'Hospitalet de Llobregat

7,447 km

CNC turning and milling center

DOOSANPUMA 3100 ULY

Call

Condition: excellent (used), Year of construction: 2012, functionality: fully functional, DOOSAN PUMA 3100ULY (2012)

CNC LATHE WITH ROTARY TOOLS AND “Y” AXIS – “Z” TRAVEL: 3,000 mm

SPECIFICATIONS:

- FANUC i Series CNC, 10.4” LCD Color Manual Guide

- Swing over bed: 850 mm

- Swing over saddle: 670 mm

- Maximum turning diameter: 420 mm

- Maximum turning length: 3,125 mm

- Axis travel: X 210 mm, Y ±60 mm, Z 3,125 mm

- Chuck size: 400 mm (*)

- Bar capacity: 102 mm

- Spindle nose: ASA A2#11

- Main spindle: 2,800 rpm, 22 kW

- Turret: 12 stations (indexing time per position: 0.25 sec)

- Rotary tool motor: 7.5 kW, 5,000 rpm

- C-axis indexing: 0.001 mm

- Tailstock travel: 3,135 mm

INCLUDED EQUIPMENT:

- Samchully MH-212 315 mm hydraulic chuck

- C axis: 360° (0.001° increments)

- Automatic tool setter

Hedpfxsx Sqkws Adwsng

- Built-in tailstock

- Programmable tailstock

- High-pressure pump

- Chip conveyor

- Mechanical, hydraulic, and electrical preparation for automatic steady rest

- SMW AUTOBLOK SLU-X-4-ZS hydraulic steady rest

- Complete standard toolholder set for internal and external machining, including 4 rotary holders (2 straight, 2 angular)

- Set of manuals (Doosan and Fanuc)

(All specifications to be confirmed)

CONDITION:

Under power, in excellent condition. Ready for inspection. Immediate delivery.

Listing

Creazzo

Creazzo

6,663 km

CNC turning and milling center

Mori SeikiNL2000 SY

Call

Condition: used, Year of construction: 2011, CNC LATHE MORI SEIKI NL 2000 SY

Year: 2011

Machine Condition: EXCELLENT

Control: Mori Seiki MSX-850

Spindle Bar Capacity: Ø 65 mm

Max Turning Diameter: 360 mm

X-Axis Travel: 260 mm

Z-Axis Travel: 590 mm

Y-Axis Travel: ± 50 mm

B-Axis + C-Axis

Rapid Traverse Rate (X, Z, B, Y): 30-30-30-10 m/min

Main Spindle Nose: A2-6

Main Spindle Speed: 5,000 rpm

Main Spindle Power: 15 kW

Sub-Spindle Nose: A2-5

Number of Driven Tool Stations: 12

Sub-Spindle Speed: 6,000 rpm

Sub-Spindle Power: 11 kW

Machine Dimensions (LxWxH): approx. 2,700 x 1,900 x 2,100 mm

INCLUDED ACCESSORY:

Hnodpfx Aex Nivaodwjg

- Chip conveyor

USED MACHINE IN EXCELLENT WORKING CONDITION, FREE OF DEFECTS OR UNDISCLOSED DAMAGE, CE COMPLIANT.

AVAILABILITY: IMMEDIATE, SUBJECT TO PRIOR SALE.

Second-hand machine in excellent condition, CE marked, free from defects or hidden damages. Delivery: Ready for dispatch, subject to prior sale.

Exclusions: VAT, services, warranty, transport, loading/unloading from truck, packaging, insurance.

Listing

Bienne

Bienne

6,984 km

CNC turning and milling machining center

DMG MORINTX 1000 -ZSM

Call

Condition: excellent (used), Year of construction: 2015, operating hours: 11,100 h, functionality: fully functional, machine/vehicle number: NTX1150102, Year 2015 with F31iB5 control and CELOS

Hsdpfxow T Snfj Adwsng

Country of manufacture: JP

Voltage: 380V/50Hz/3ph

Dimensions: 4169x2543x2543 mm

Net machine weight: 10,000 kg

TECHNICAL SPECIFICATIONS

Control: Fanuc F31iB5 with CELOS

Main spindle:

X1 axis: 455 mm

Y axis: +/- 105 mm

Z1 axis: 800 mm (+165 for ATC)

B axis: 240°

Turret 2:

X2 axis: 160 mm

Z2 axis: 730 mm

Spindle 1 / Spindle 2:

C axis: 360° / 360°

Tailstock:

A axis: 820 mm

Max. distance between centres: 1,050 mm

Max. turning diameter

Main spindle: Ø 430 mm

Turret 2: Ø 274 mm

Max. turning length: 800 mm

Bar diameter: Ø 52 mm . Ø 65 mm

Unless otherwise specified or in case of errors or omissions, the technical data is provided without commitment.

Listing

Bienne

Bienne

6,984 km

CNC turning and milling machining center

DMG MORINLX1500SY/500

Call

Condition: excellent (used), Year of construction: 2020, operating hours: 4,800 h, functionality: fully functional, machine/vehicle number: NL154200702, Manufacturing origin: JP

Voltage: 380 V / 50 Hz / 3-phase

Net weight: 5,400 kg

Customs tariff number: 8458.9100

TECHNICAL DATA

Maximum turning diameter: 350 mm

Turning length: 515 mm

CNC control: M730UM MAPPS Celos

Swing over bed: 923.8 mm

Swing diameter above carriage: 755 mm

Standard turning diameter: 260 mm

Bar capacity: 34 mm

Main spindle:

Spindle speed range: 100 – 8,000 rpm

Spindle motor power: 11 / 7.5 kW

C-axis resolution: 0.001°

Chuck diameter: 210 mm

Subspindle:

Maximum speed: 8,000 rpm

Spindle nose: A2-5

Axis travels:

X-axis travel: 260 mm

Z-axis travel: 580 mm

Y-axis travel: 100 mm (±50 mm)

Turret:

Number of turret stations: 20

Driven stations: 20

Tool shank diameter: 25 mm

Maximum driven tool speed: 10,000 rpm

Hnjdpfx Adew T Sn Eewog

Driven tool motor power: 5.5 / 3.7 kW

Feed rates:

Rapid traverse X-axis: 30 m/min

Rapid traverse Z-axis: 30 m/min

Rapid traverse subspindle: 30 m/min

Rapid traverse Y-axis: 10 m/min

Rapid traverse C-axis: 400 rpm

Total power requirement: 31 kVA

Approximate machine weight: 5.4 t

Approximate machine dimensions: 4.0 x 3.0 x 3.2 m

Errors and omissions excepted – data provided without obligation.

We make it easier for you to find: "milling center"

You will receive new offers immediately and free of charge via e-mail

You can easily terminate the search request at any time

Used Milling Center (19,973)

Search Machineseeker now with more than 2,00,000 used machines:Browse through the most popular machine descriptions:

- Bed Type Milling

- Center

- Center Lathe

- Centering

- Cnc Center

- Cnc Milling Center

- Cnc Milling Machining Center

- Cnc Turning And Milling Center

- Cnc Vertical Milling Center

This may be of interest to you

Get information now

+44 20 806 810 84

+44 20 806 810 84

List now

*per listing / month